Positive electrode and positive electrode paste with high energy density, and battery containing positive electrode

A high-energy density, positive electrode slurry technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor long cycle life, poor cell rate, low battery energy density, etc., and achieve excellent low-temperature discharge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

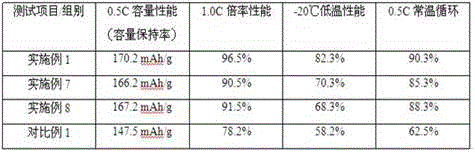

Embodiment 1

[0044] This embodiment provides a positive electrode slurry with high energy density, which includes the following components in parts by weight:

[0045] 100 parts of positive electrode active material;

[0046] Composite conductive agent 0.04 part;

[0047] 0.9 parts of polyvinylidene fluoride;

[0048] 42.4 parts of N-methylpyrrolidone;

[0049] The composite conductive agent includes single-wall carbon nanotubes and graphene, and the mass ratio of single-wall carbon nanotubes and graphene is 3:1;

[0050] Single-walled carbon nanotubes are composed of a single cylindrical graphite layer with a specific surface area of 600m 2 / g, the tube diameter is 1.2nm, the tube length is greater than 5μm, and the electron mobility is greater than 2×10 5 cm2 / V·s.

[0051] The specific surface area of graphene is 2000m 2 / g or more, the electron mobility of graphene is greater than or equal to 1.5×10 5 cm2 / V·s.

[0052] Its preparation method comprises the following steps:

...

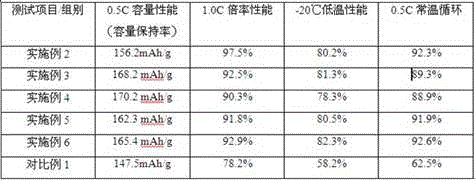

Embodiment 2

[0059] Different from Example 1, the positive electrode slurry with high energy density provided in this example includes the following components in parts by weight:

[0060] 100 parts of lithium nickel cobalt manganate;

[0061] Composite conductive agent 0.08 part;

[0062] 0.9 parts of polyvinylidene fluoride;

[0063] 46.9 parts of N-methylpyrrolidone;

[0064] The mass ratio of single-walled carbon nanotubes to graphene is 2:1; the specific surface area of single-walled carbon nanotubes is 550m 2 / g, the tube diameter is 1.5nm.

[0065] Its preparation method comprises the following steps:

[0066] In the first step, add polyvinylidene fluoride dry powder into N-methylpyrrolidone, and stir evenly in a power mixing device for 3.3 hours to prepare polyvinylidene fluoride glue;

[0067] In the second step, the single-walled carbon nanotube dry powder is mixed with the graphene dry powder, polyethylene glycol is added, and the conductive glue is dispersed in the grind...

Embodiment 3

[0071] Different from Example 1, the positive electrode slurry with high energy density provided in this example includes the following components:

[0072] 100 parts of lithium manganate;

[0073] Composite conductive agent 0.03 part;

[0074] 2.2 parts of polyvinylidene fluoride;

[0075] 47.5 parts of N-methylpyrrolidone;

[0076] The mass ratio of single-walled carbon nanotubes to graphene is 5:1; the specific surface area of single-walled carbon nanotubes is 650m 2 / g, the tube diameter is 1.0nm.

[0077] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com