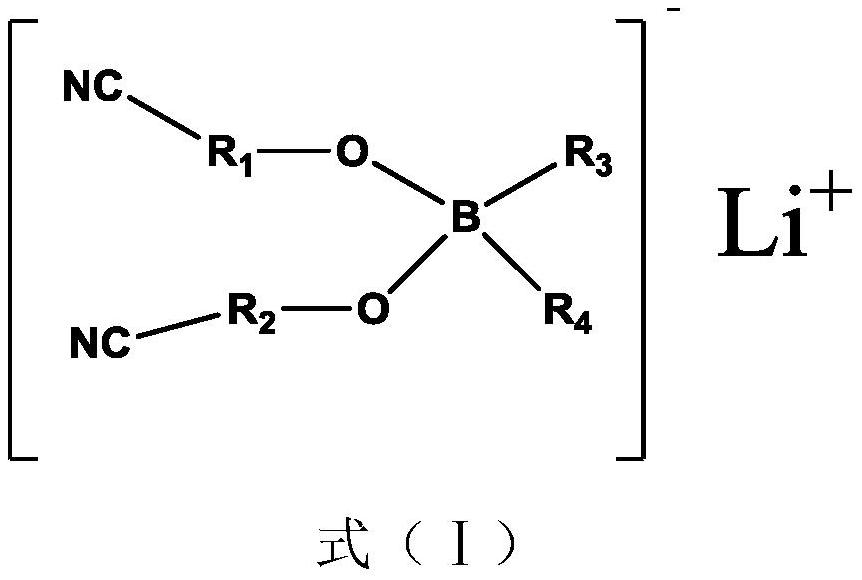

Low-temperature electrolyte and lithium ion battery comprising same

An electrolyte and low temperature technology, which is applied in the field of lithium-ion batteries, can solve the problems of low conductivity of lithium salts, achieve high ion conductivity, enhance wettability, and solve the effect of lithium precipitation on the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Embodiment 1 Electrolyte 1 and Experimental Battery 1

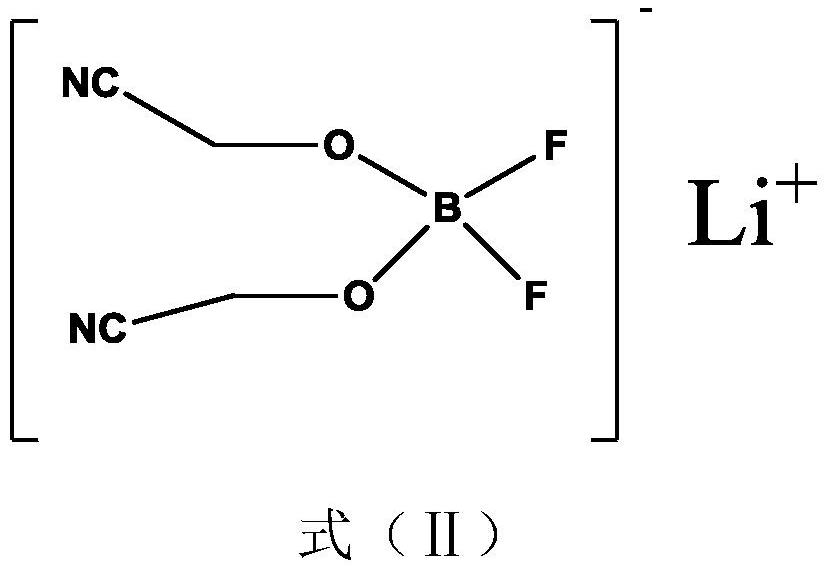

[0024] (1) Preparation of Electrolyte 1: In a glove box filled with argon (moisture <0.1ppm, oxygen <0.1ppm), ethylene carbonate, diethyl carbonate, and dimethyl carbonate were mixed in a weight ratio of 3:2 : 5 to mix evenly, then slowly add lithium dicyanoalkoxy haloborate (formula (II)) accounting for 12% of the total weight of the electrolyte, and add 1% of the total weight of the electrolyte after the lithium salt is completely dissolved. Ethylene carbonate was stirred evenly to obtain electrolyte solution 1.

[0025]

[0026] (2) Preparation of positive electrode material: NCM523, acetylene black and PVDF (binder) are mixed according to the weight ratio of 90:5:5, and N-methylpyrrolidone is added to make a slurry, and the slurry is coated on 12 microns On a thick aluminum foil, after drying, it is rolled to obtain the positive electrode material.

[0027] (3) Preparation of negative electr...

Embodiment 2

[0029] Embodiment 2 Preparation of Electrolyte 2 and Experimental Battery 2

[0030] The only difference from Example 1 is that during the preparation of electrolyte solution 2, lithium dicyanoalkoxy haloborate (formula (III)) accounting for 9% of the total weight of the electrolyte solution was added, and after the lithium salt was completely dissolved, 2% of the electrolyte solution was added. 1% by total weight of fluoroethylene carbonate.

[0031]

Embodiment 3

[0032] Embodiment 3 Preparation of Electrolyte 3 and Experimental Battery 3

[0033] The only difference from Example 1 is that during the preparation of electrolyte solution 3, lithium dicyanoalkoxy haloborate (formula (IV)) accounting for 14% of the total weight of the electrolyte solution was added, and the electrolyte solution was added after the lithium salt was completely dissolved. 1% by total weight of fluoroethylene carbonate.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com