Fabric and method for producing same

A technology of stretching nets and webs, which is applied in the direction of textiles and papermaking, papermaking, papermaking machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

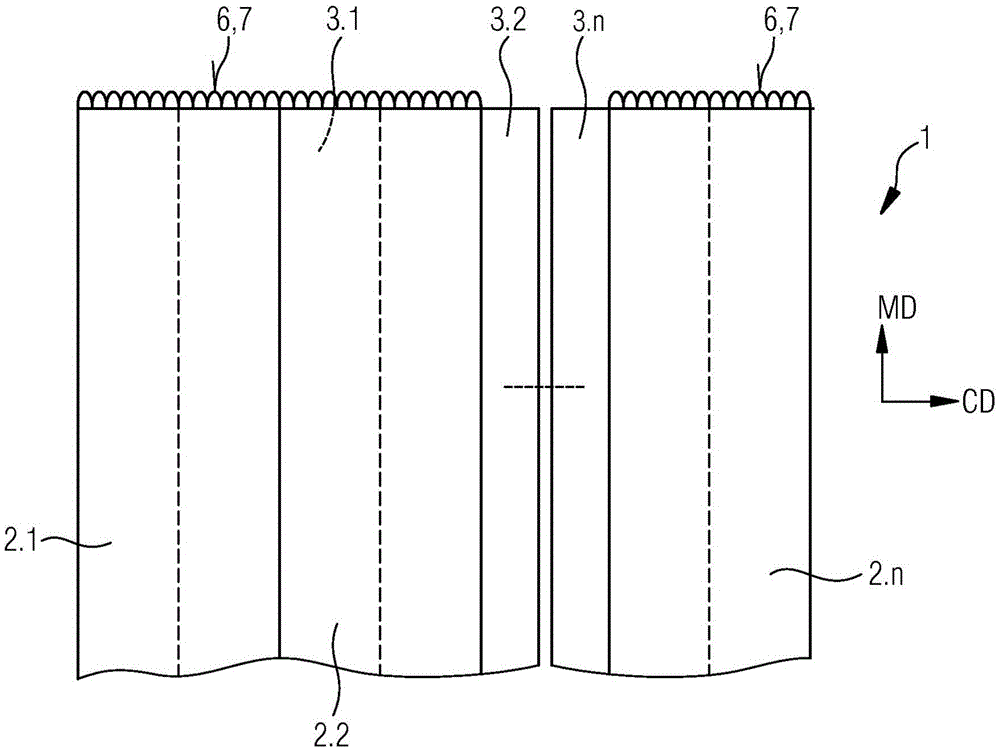

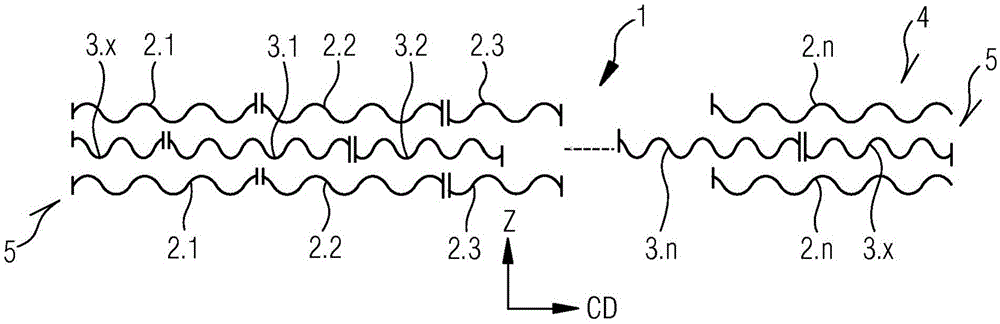

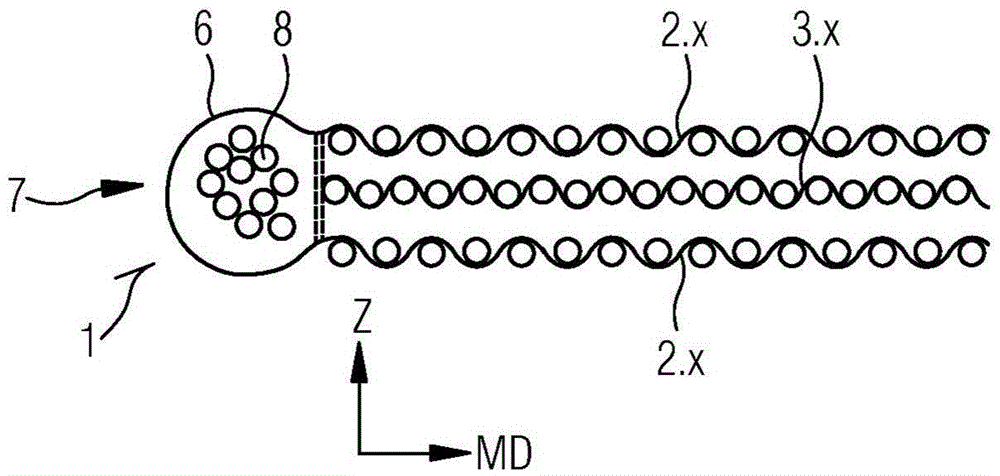

[0047] figure 1 A schematic view of a stretched wire 1 is shown, which can be embodied in particular as a press felt, but can also be implemented in the type according to the invention as forming screens and drying screens and as well as by adding polymer components. other stretched mesh types like the finished conveyor belt.

[0048] In this case, the stretched web 1 consists of a plurality of substantially parallel strips 2.1, 2.2...2.n, which together form the overall width of the stretched web 1 . Here, the strips 2.1, 2.2...2.n are produced in the manner described below. First, a surface is produced, which can be produced, for example, in a known manner as a flat woven fabric of warp threads and weft threads which cross each other in any weaving pattern. Alternatively, it is also possible to use a helical structure which has a plurality of plastic wraps which are interwoven and are connected to each other with patch cords. Prefabricated strips, non-crimp fabrics, warp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com