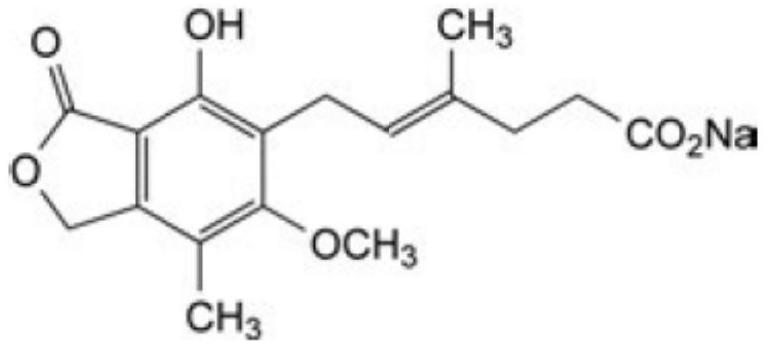

Preparation method of high-purity M2 crystal form mycophenolate sodium

A mycophenolate sodium, high-purity technology, applied in the field of preparation of high-purity M2 crystal form mycophenolate sodium, can solve the problem of not meeting the quality requirements well, not mentioning the influence of crystal form transformation, and not being suitable for preparation production Use and other issues to achieve the effect of easy industrial scale promotion and application, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 A kind of preparation method of high-purity M2 crystal form mycophenolate sodium

[0051] The preparation method of described high-purity M2 crystal form mycophenolate sodium, comprises the steps:

[0052] S1. Use sodium carbonate to adjust the pH of 5L mycolic acid fermentation broth to 11, stir at room temperature for 2 hours, filter to obtain the filtrate, wash with water with pH 11, collect the top washing liquid, combine the top washing liquid and the filtrate, and obtain 5L of mycolic acid containing Mixture A of sodium phenate;

[0053] S2. Cool the mixed liquid A obtained in step S1 to 7°C, add sulfuric acid solution to adjust the pH to 4, let it stand for 1 hour, and filter to obtain 57g of precipitate;

[0054] S3. Dissolve 57g of the precipitate obtained in step S2 in 1000ml of methyl isobutyl ketone at 55°C to obtain a solution; add 4.6g of activated carbon to the solution, stir at 50°C for 20 minutes, and Filter the diatomaceous earth layer, ...

Embodiment 2

[0058] Embodiment 2 A kind of preparation method of high-purity M2 crystal form mycophenolate sodium

[0059] The preparation method of described high-purity M2 crystal form mycophenolate sodium, comprises the steps:

[0060] S1. Adjust the pH of 5L of mycolic acid fermentation broth to 10 with sodium carbonate, stir at room temperature for 2 hours, filter to obtain the filtrate, wash with pH 10 water, collect the top wash, and combine the top wash and filtrate to obtain 5.5 L of wheat-containing Mixture A of Sodium Corfenol;

[0061] S2. Cool the mixed solution A obtained in step S1 to 6° C., add sulfuric acid solution to adjust the pH to 3, let it stand for 1 hour, and filter to obtain 55 g of precipitate;

[0062] S3. Dissolve 55g of the precipitate obtained in step S2 in 1650ml of butyl acetate at 40°C to obtain a solution; add 4.5g of activated carbon to the solution, stir at 40°C for 30 minutes, and pass through a diatomite layer Filter, then wash the diatomite with 11...

Embodiment 3

[0066] Embodiment 3 A kind of preparation method of high-purity M2 crystal form mycophenolate sodium

[0067] The preparation method of described high-purity M2 crystal form mycophenolate sodium, comprises the steps:

[0068] S1. Adjust the pH of 5L of mycolic acid fermentation broth to 12 with sodium carbonate, stir at room temperature for 2 hours, filter to obtain the filtrate, wash with pH 12 water, collect the top wash, combine the top wash and filtrate to obtain 5.5 L of wheat-containing Mixture A of Sodium Corfenol;

[0069] S2. Cool the mixed solution A obtained in step S1 to 9°C, add sulfuric acid solution to adjust the pH to 5, let it stand for 1 hour, and filter to obtain 55g of precipitate;

[0070] S3. Dissolve 55g of the precipitate obtained in step S2 in 1100ml of ethyl acetate at 60°C to obtain a solution; add 5.5g of activated carbon to the solution, stir at 60°C for 15 minutes, and pass through a diatomite layer Filter, then wash the diatomite with 83ml of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com