High-concentration sodium hypochlorite co-production device and method

A sodium hypochlorite, high-concentration technology, applied in the direction of hypochlorous acid, hypochlorite, chemical instruments and methods, etc., can solve problems such as sodium hypochlorite, blocked tubes, and affecting heat transfer of tubes in falling film absorbers, etc., to achieve The effect of complete reaction and exothermic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

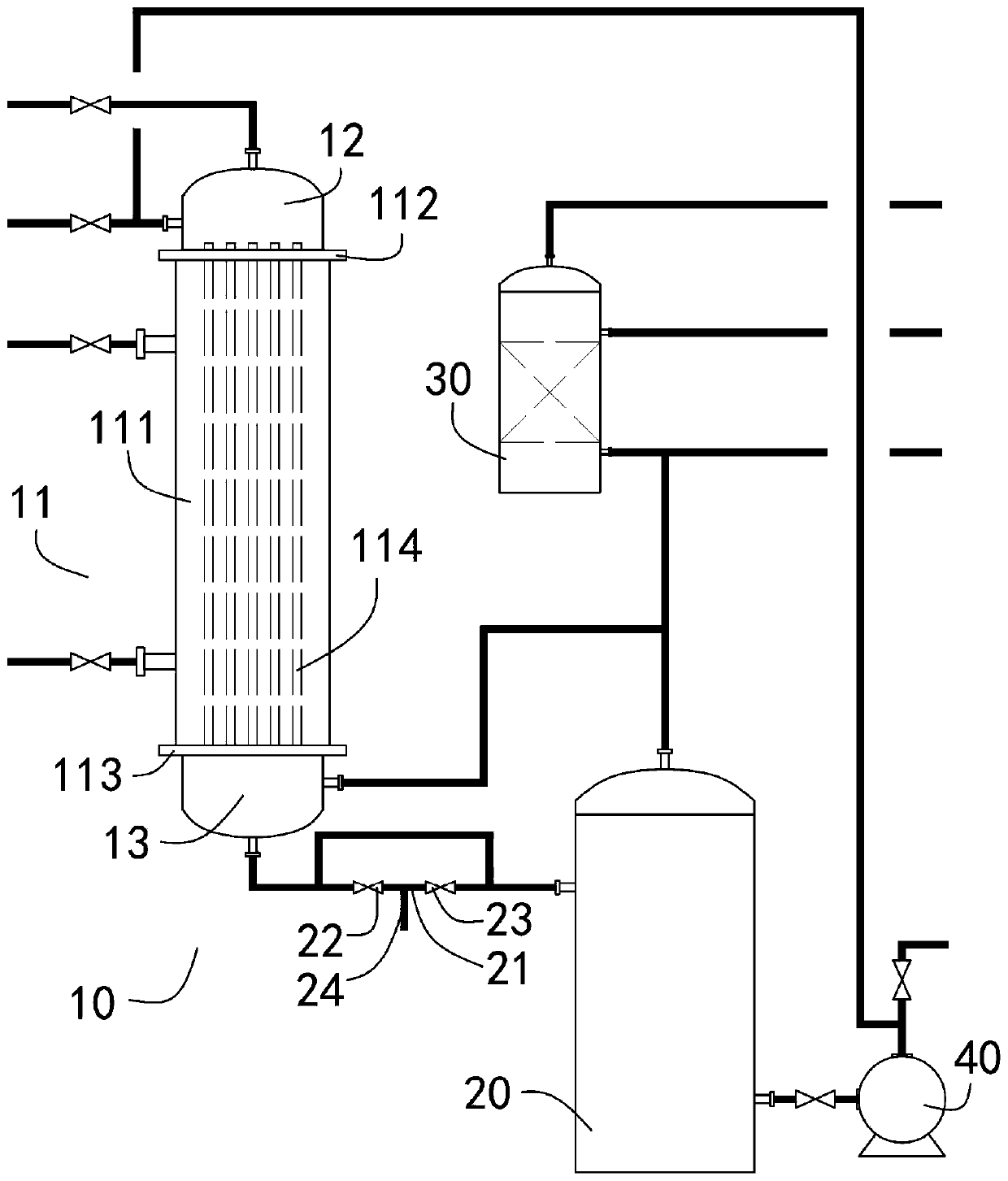

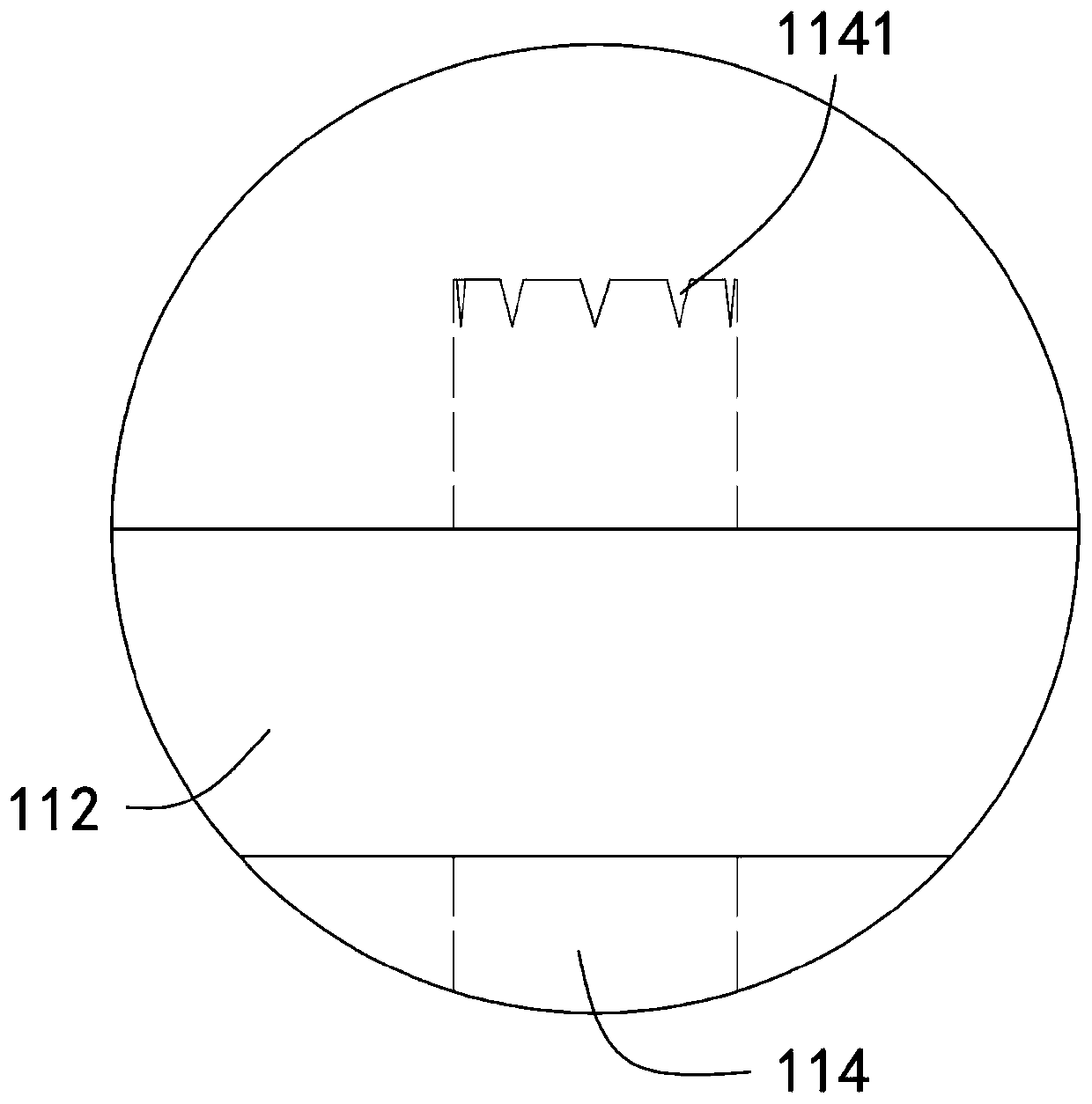

[0048] Embodiment 1: Sodium hydroxide solution is mixed with 5m 3 The flow rate of / h passes into the receiving chamber from the liquid phase inlet of the upper head 12, and after the sodium hydroxide solution fills the bottom surface of the receiving chamber, it flows into the cooling row pipe 114 from a plurality of overflow grooves 1141 densely distributed on the upper end surface of the cooling row pipe 114 In the tube, the sodium hydroxide solution flows down into the collection chamber along the inner wall of the cooling tube 114, and forms a liquid film with a uniform thickness on the inner wall of the cooling tube 114, and passes excess dry chlorine gas from the gas phase inlet of the upper head 12 into the receiving chamber. Chlorine gas flows downward along the inner wall of the cooling tube 114, and reacts with the sodium hydroxide on the inner wall of the cooling tube 114, and sends the reaction product in the collection chamber into the middle tank 20, and detects ...

Embodiment 2

[0049] Embodiment 2: Sodium hydroxide solution is mixed with 5m 3 The flow rate of / h passes into the receiving chamber from the liquid phase inlet of the upper head 12, and after the sodium hydroxide solution fills the bottom surface of the receiving chamber, it flows into the cooling row pipe 114 from a plurality of overflow grooves 1141 densely distributed on the upper end surface of the cooling row pipe 114 In the tube, the sodium hydroxide solution flows down into the collection chamber along the inner wall of the cooling tube 114, and forms a liquid film with a uniform thickness on the inner wall of the cooling tube 114, and passes excess dry chlorine gas from the gas phase inlet of the upper head 12 into the receiving chamber. Chlorine gas flows downward along the inner wall of the cooling tube 114, and reacts with the sodium hydroxide on the inner wall of the cooling tube 114, and sends the reaction product in the collection chamber into the middle tank 20, and detects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com