Method for preparing chromate-free passivation film capable of improving oxidative resistance of chemical plating Ni-P layer

A technology of oxidation resistance and chromium-free passivation, which is applied in the direction of liquid chemical plating, coating, metal material coating process, etc., can solve the problems of high implementation temperature, environmental pollution, technical difficulty, etc., and achieve oxidation resistance Excellent performance, broad market prospects and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

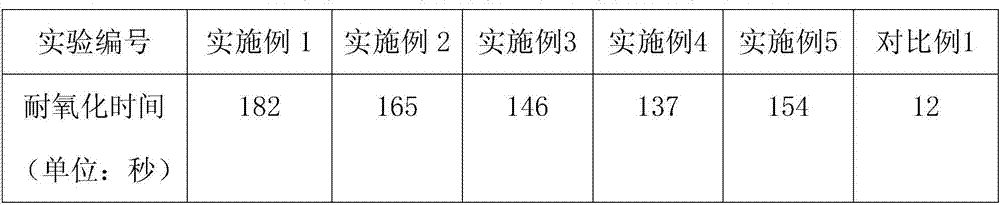

Embodiment 1

[0022] The present invention comprises the following steps:

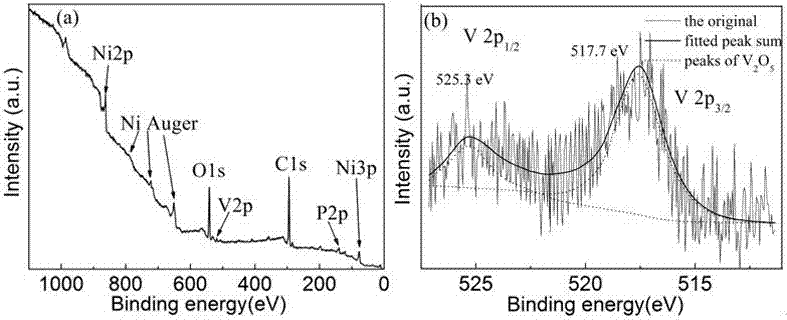

[0023] Step 1. At ambient temperature of 25°C, mix 6.1g of VO 3 - Salt-NaVO 3 Dissolve in 1L deionized water to adjust the content of VO 3 - The molar concentration of the solution is 0.05mol / L, and the molar concentration of 1mol / L nitric acid is used to adjust the concentration of VO 3 - The pH value of the solution is 1.3, and the passivation solution is prepared for subsequent use;

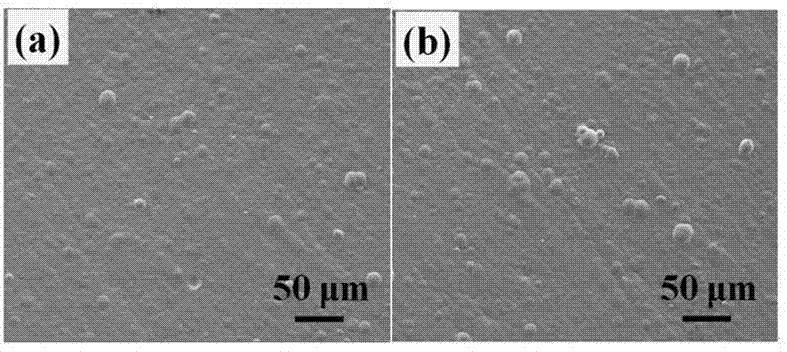

[0024] Step 2. Rinse the electroless Ni-P layer newly made on the surface of the part with deionized water to remove impurities on the surface of the Ni-P layer;

[0025] Step 3. Immerse the parts in step 2 into the passivation solution in step 1 at room temperature with an ambient temperature of 25°C for 30 minutes;

[0026] Step 4. Take the parts out of the passivation solution;

[0027] Rinse the parts with deionized water to form a chromium-free passivation film with strong oxidation resistance on the electroless Ni-P la...

Embodiment 2

[0030] The present invention comprises the following steps:

[0031] Step 1. At ambient temperature of 25°C, mix 12.2g of VO 3 - Salt-NaVO 3 Dissolve in 1L deionized water to adjust the content of VO 3 - The molar concentration of the solution is 0.1mol / L, and the molar concentration of 1mol / L nitric acid is used to adjust the concentration of VO 3 - The pH value of the solution is 1.3, and the passivation solution is prepared for subsequent use;

[0032] Step 2. Rinse the electroless Ni-P layer newly made on the surface of the part with deionized water to remove impurities on the surface of the Ni-P layer;

[0033] Step 3. Immerse the parts in step 2 into the passivation solution in step 1 at an ambient temperature of 25°C for 120 minutes;

[0034] Step 4. Take the parts out of the passivation solution;

[0035] Rinse the parts with deionized water to form a chromium-free passivation film with strong oxidation resistance on the electroless Ni-P layer on the surface of...

Embodiment 3

[0038] The present invention comprises the following steps:

[0039] Step 1. At ambient temperature of 25°C, mix 6.1g of VO 3 - Salt-NaVO 3 Dissolve in 1L deionized water to adjust the content of VO 3 - The molar concentration of the solution is 0.05mol / L, and the molar concentration of 1mol / L nitric acid is used to adjust the concentration of VO 3 - The pH value of the solution is 1.0, and the passivation solution is prepared for subsequent use;

[0040] Step 2. Rinse the electroless Ni-P layer newly made on the surface of the part with deionized water to remove impurities on the surface of the Ni-P layer;

[0041] Step 3. Immerse the parts in step 2 into the passivation solution in step 1 at room temperature with an ambient temperature of 25°C for 10 minutes;

[0042] Step 4. Take the parts out of the passivation solution;

[0043] Rinse the parts with deionized water to form a chromium-free passivation film with strong oxidation resistance on the electroless Ni-P la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com