Insulator-coated powder for magnetic member

A technology of insulating coating and magnetic components, which is applied in the direction of magnetic materials, magnetic objects, and the magnetism of inorganic materials, and can solve problems such as deterioration of absorption characteristics, reduction of magnetic permeability, and insufficient insulation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

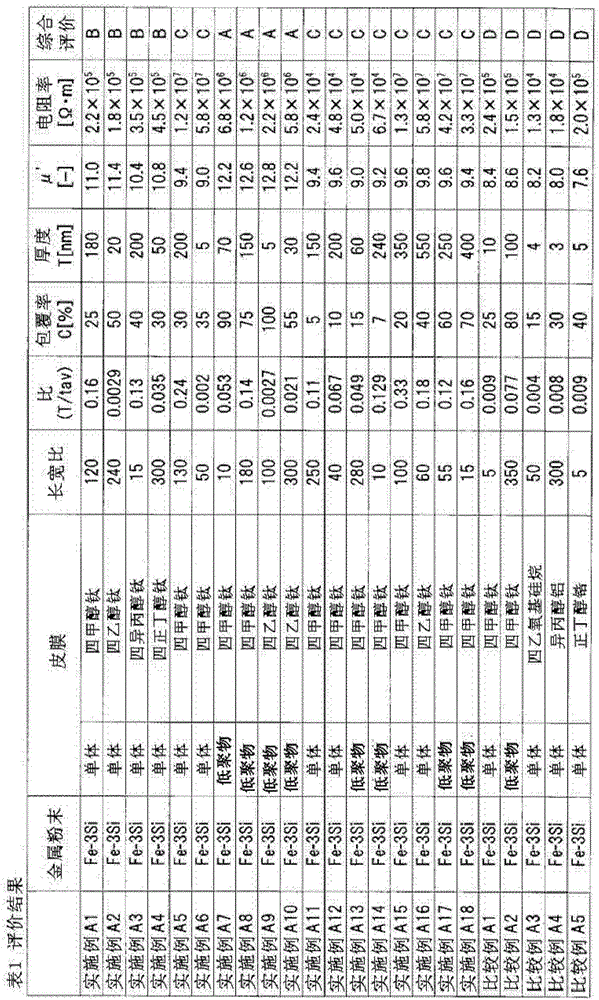

Embodiment A1~A36 and comparative example A1~A10

[0051] Production and evaluation of a magnetic member using the flat powder for a magnetic member whose coating film is composed of a polymer containing a substance containing titanium alkoxides was performed as follows.

[0052] [Production of magnetic sheet (magnetic member)]

[0053] Before the preparation of the magnetic sheet, the powders of the respective examples shown in Tables 1 and 2 below were produced. In the production of this powder, a powder (10 kg) composed of countless metal powders was prepared. This powder was processed with an attritor, and each metal powder was flattened. In addition, as the metal powder, Fe-3mass%Si powder and Fe-9.5mass%Si-5.5mass%Al powder were used.

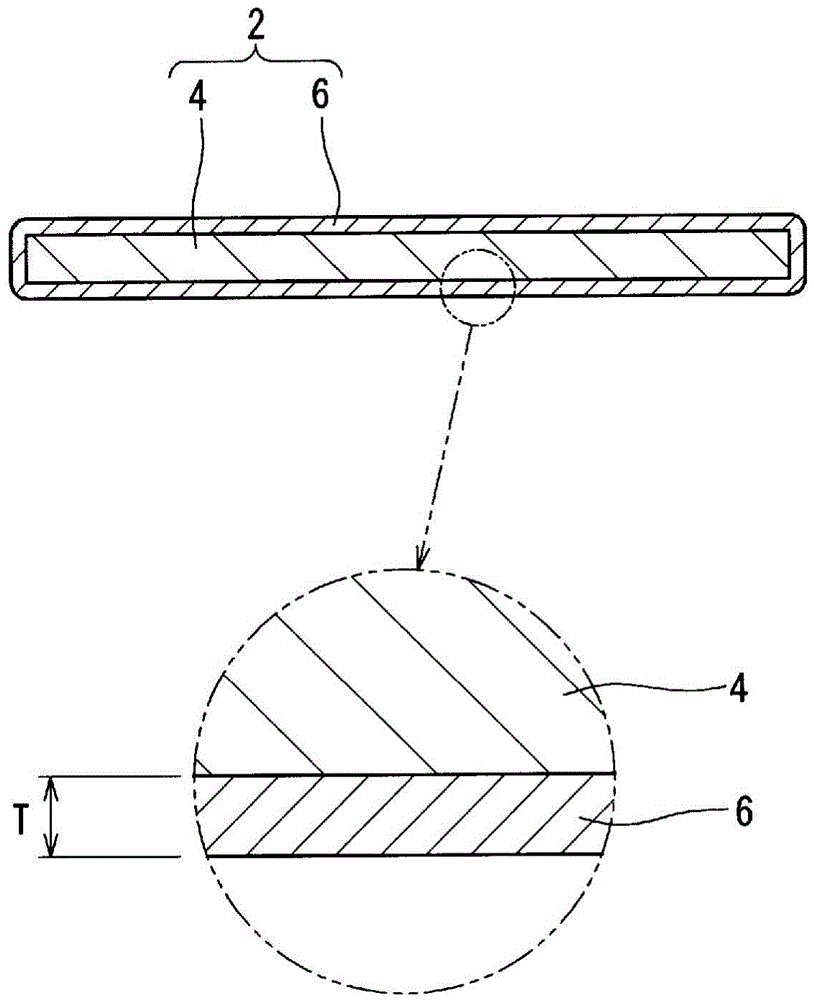

[0054] Using a treatment solution containing titanium alkoxides, a film is formed on flattened metal powder to produce figure 1 Insulation coated flat powder shown. The types of titanium alkoxides used in this production are shown in Tables 1 and 2 below. The titanium alkoxide oligom...

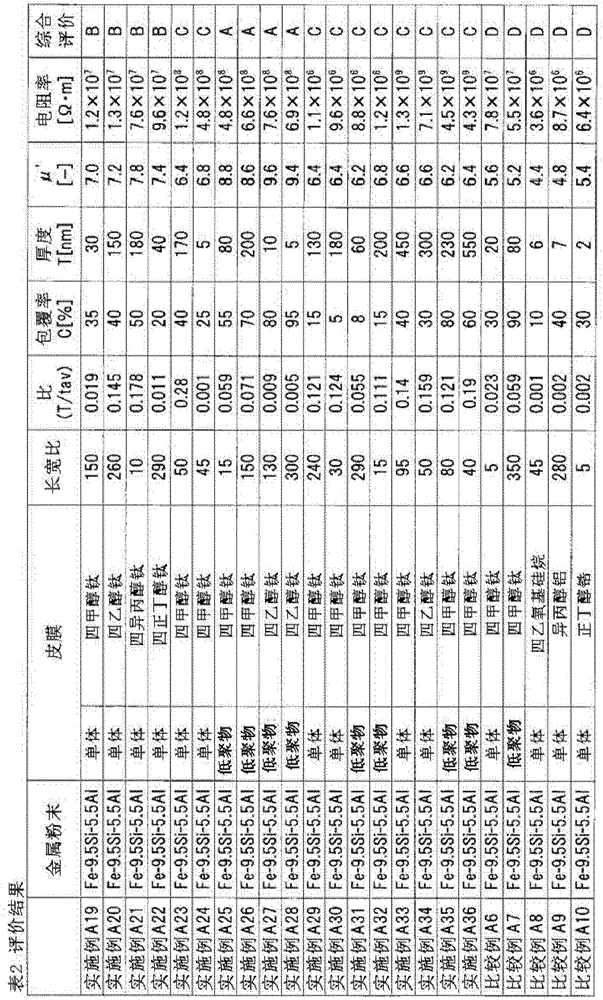

Embodiment B1~B32 and comparative example B1~B4

[0084] Production and evaluation of a magnetic member using a flat powder for a magnetic member whose coating film contains a polymer containing titanium alkoxides and silicon alkoxides was performed as follows.

[0085] [Production of magnetic sheet (magnetic member)]

[0086] Before the preparation of the magnetic sheet, the powders of the respective examples shown in Tables 3 and 4 below were produced. In the production of this powder, a powder (10 kg) composed of countless metal powders was prepared. This powder was processed with an attritor, and each metal powder was flattened. In addition, as the metal powder, Fe-3mass%Si powder and Fe-9.5mass%Si-5.5mass%Al powder were used.

[0087] Using a treatment solution containing titanium alkoxides and silicon alkoxides, a film is formed on flattened metal powder to produce figure 1 Insulation coated flat powder shown. The types of titanium alkoxides and silicon alkoxides used in this production are shown in Tables 3 and 4 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com