Machining method of deep and narrow arc grooves for nickel-based superalloy turbine guide vanes

A turbine guide vane, nickel-based high-temperature alloy technology, applied in metal processing equipment, manufacturing tools, bonded grinding wheels, etc., can solve the problem that the surface integrity of the workpiece is difficult to be guaranteed, the surface technical requirements cannot be met, and the surface of the workpiece is deeply ground. Marks and other problems, to achieve the effect of solving the problem of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

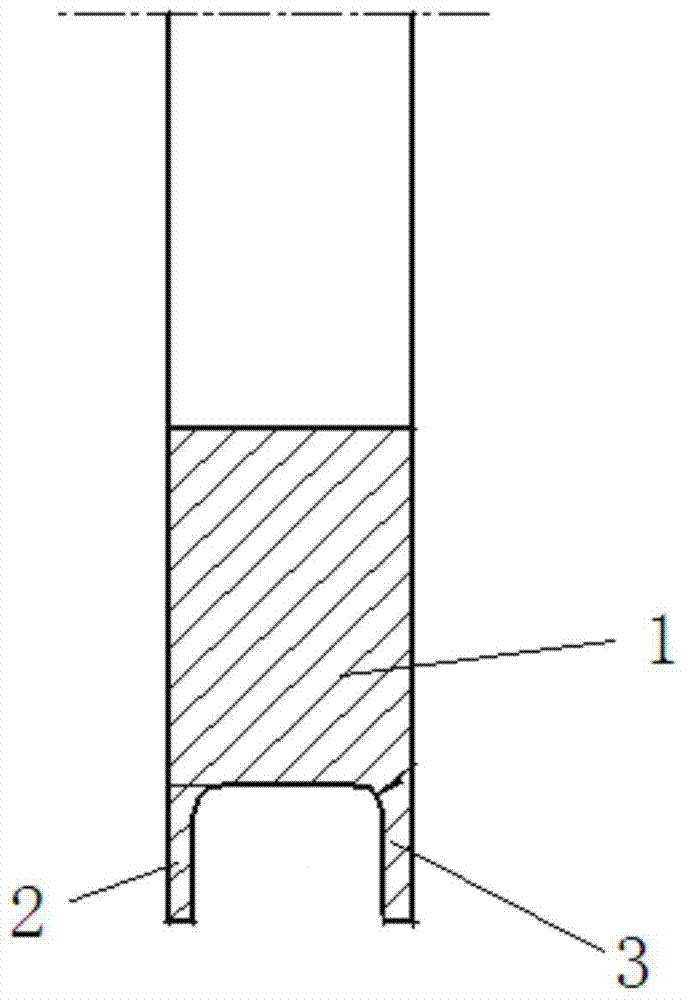

Image

Examples

Embodiment 1

[0012] Production preparation, lower abrasive formula, simultaneous rough turning of aluminum base with mixed materials, grinding wheel blank forming, rough turning of grinding wheel base, fine turning of grinding wheel base, outer circle dressing of grinding wheel, appearance treatment, final inspection. The material of the primary grinding wheel is proportioned by volume: superfine white corundum 9 with a particle size of 40 μm, and SiO with a particle size of 0.5 μm 2 11. Nano TiO with a particle size of 0.05 μm 2 1, FeS 3; polycrystalline diamond 10, CBN25; the material ratio of the secondary grinding wheel is as follows: the particle size is 20 μm superfine white corundum 8, the particle size is 0.1 μm SiO 2 11-12, the particle size is 0.03μm nano TiO 2 1, FeS1; polycrystalline diamond 1, CBN15;

Embodiment 2

[0014] Production preparation, lower abrasive formula, simultaneous rough turning of aluminum base with mixed materials, grinding wheel blank forming, rough turning of grinding wheel base, fine turning of grinding wheel base, outer circle dressing of grinding wheel, appearance treatment, final inspection. The material of the primary grinding wheel is proportioned by volume: superfine white corundum 8 with a particle size of 30 μm, and SiO with a particle size of 0.3 μm 2 12. Nano TiO with a particle size of 0.03 μm 2 10, FeS 1; polycrystalline diamond 1, CBN20; the material ratio of the secondary grinding wheel is as follows: the particle size is 10 μm superfine white corundum 5, the particle size is 0.2 μm SiO 2 12. Nano TiO with a particle size of 0.05 μm 2 10, FeS3; polycrystalline diamond 10, CBN10;

Embodiment 3

[0016] Production preparation, lower abrasive formula, simultaneous rough turning of aluminum base with mixed materials, grinding wheel blank forming, rough turning of grinding wheel base, fine turning of grinding wheel base, outer circle dressing of grinding wheel, appearance treatment, final inspection.

[0017] The material of the initial grinding wheel is proportioned by volume: the particle size is 35 μm superfine white corundum 8.5, the particle size is 0.4 μm SiO 2 12. Nano TiO with a particle size of 0.04μm 2 6, FeS 2; polycrystalline diamond 6, CBN23; the material ratio of the secondary grinding wheel is: the particle size is 15 μm ultrafine white corundum 6, the particle size is 0.1 μm SiO 2 11. Nano TiO with a particle size of 0.04 μm 2 6, FeS 1-3; polycrystalline diamond 6, CBN12;

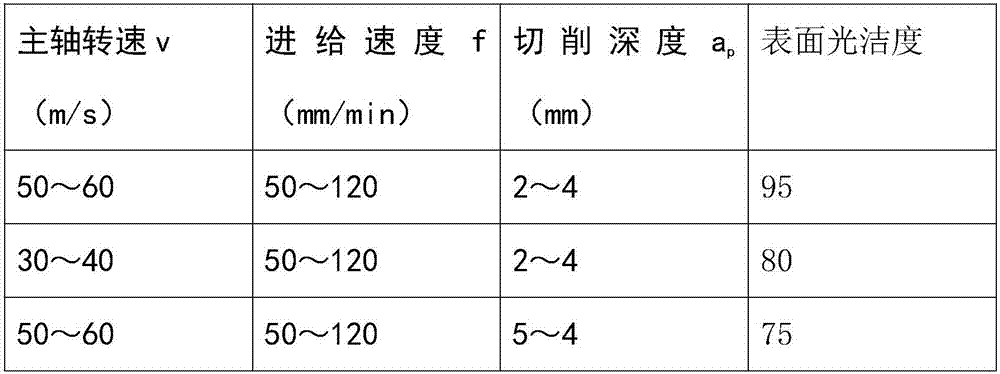

[0018] The grinding parameters of the CBN grinding wheel in the above embodiment are: the spindle speed is 50-60 m / s, the feed rate is 50-120 mm / min, and the cutting depth is 2-4 mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com