High-performance nylon composite material and preparation method thereof

A nylon composite material and high-performance technology, applied in the field of high-performance nylon composite materials and their preparation, can solve the problems of decreased heat resistance and thermo-oxidative stability, exposed fibers, and affected smoothness, etc., and achieve improved mechanical properties, physical and chemical properties. Improves, maintains stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

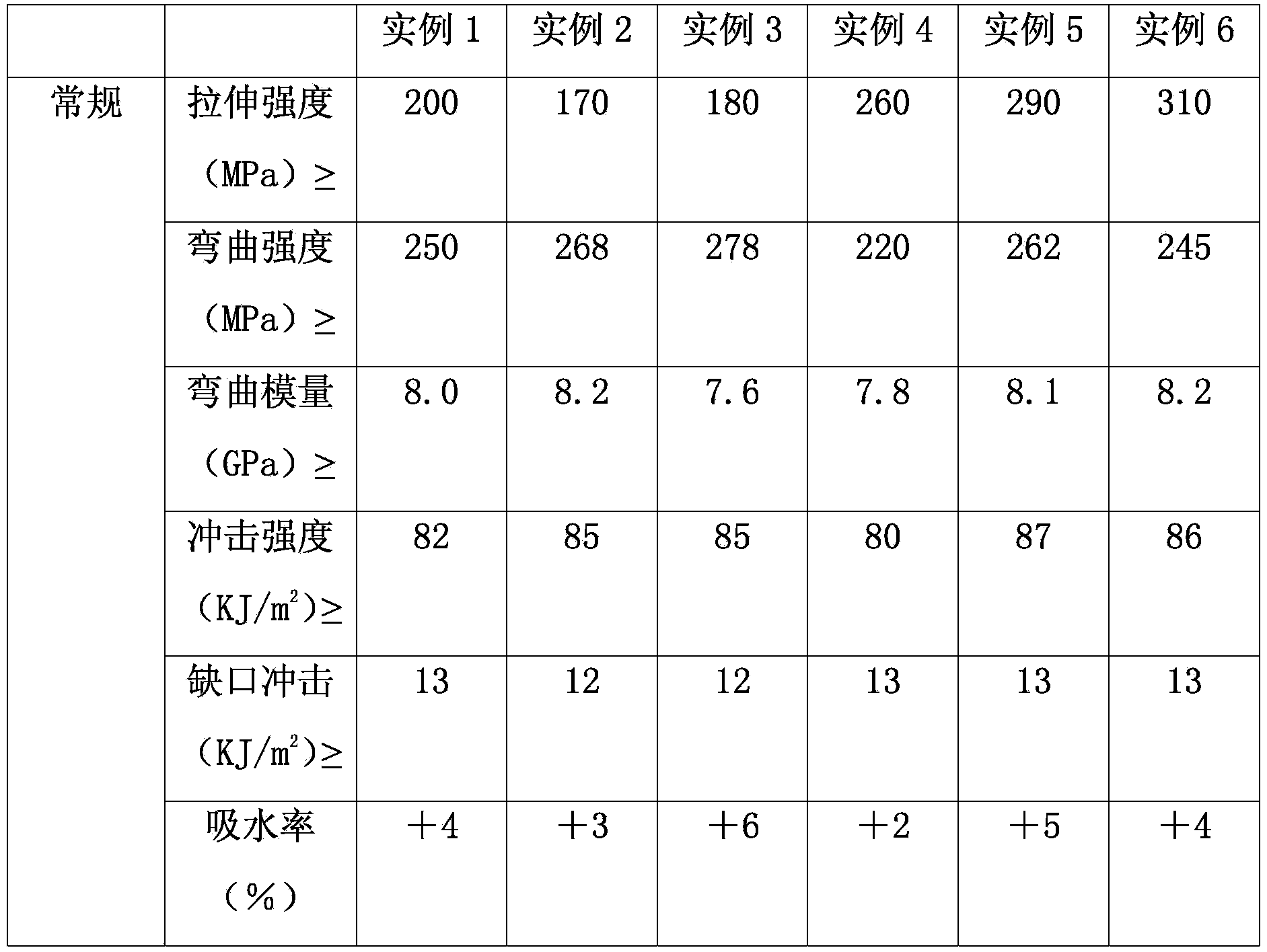

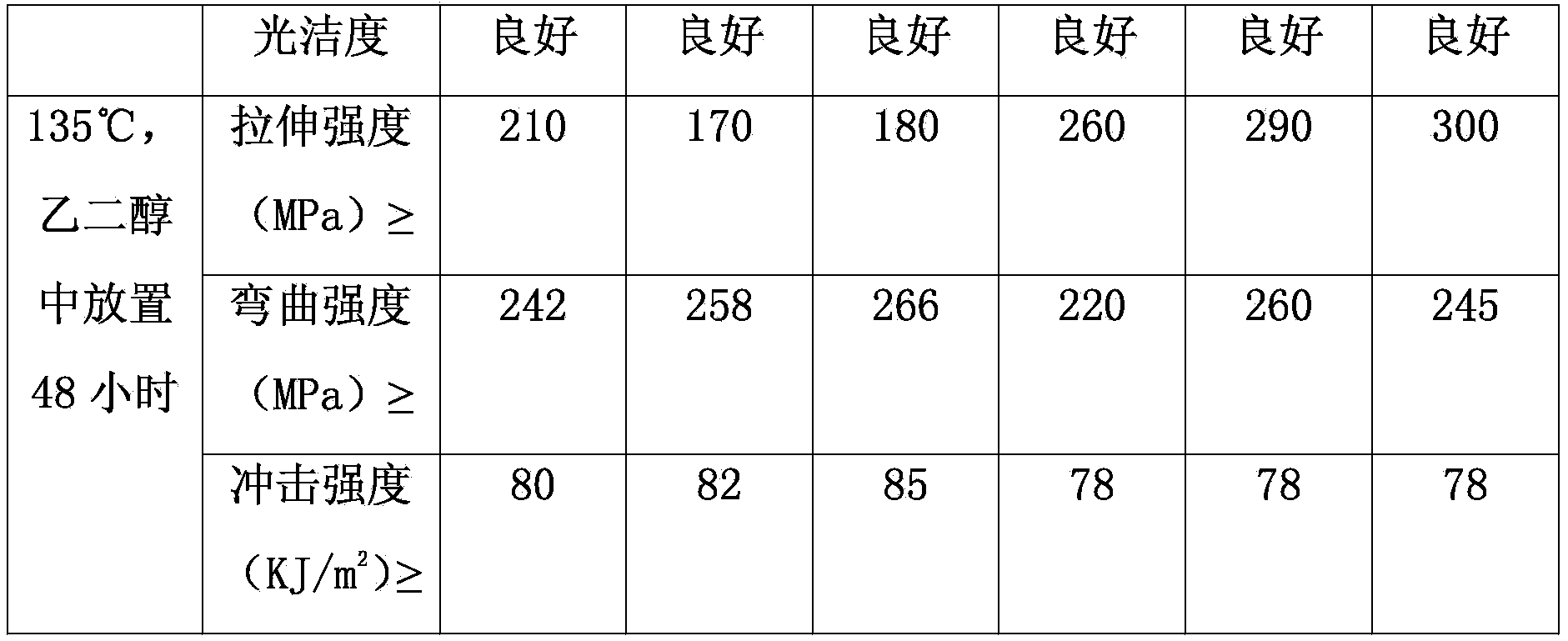

Examples

Embodiment 1

[0036] Example 1: E-glass fiber reinforced nylon composite material, consisting of the following components:

example 1

[0037] Example 1 The mixture of nylon 66 and nylon 6 (weight ratio is 2:1) 55%, alkali-free glass fiber (Chongqing International Composite Materials Co., Ltd., ECS401AD, diameter 13um, length 4mm) 30%, silicone and ethylene double rigid Fatty acid amide (weight ratio of 1:1) 1.0%, montmorillonite nanocomposite material 8%, EPDM 6%.

example 2

[0038] Example 2 The mixture of nylon 66 and nylon 6 (weight ratio is 4:1) 60%, alkali-free glass fiber (length 12mm) 20%, silicone and ethylene bis-stearic acid amide (weight ratio is 1:1) 1.2 %, montmorillonite nanocomposite material 7%, EPDM 6%, dyeing agent (black masterbatch) 0.6%, hydrolysis-resistant agent 0.2% (Bruggerman, hydrolysis-resistant agent H3337).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com