Cleaning solution used after IC copper process CMP and preparation method thereof

A technology of cleaning solution and chelating agent, applied in the preparation of detergent mixture composition, chemical instruments and methods, detergent composition, etc., can solve the problem of increased surface roughness, excessive loss of substrate, skin irritation, etc. problems, to achieve the effect of short cleaning time, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

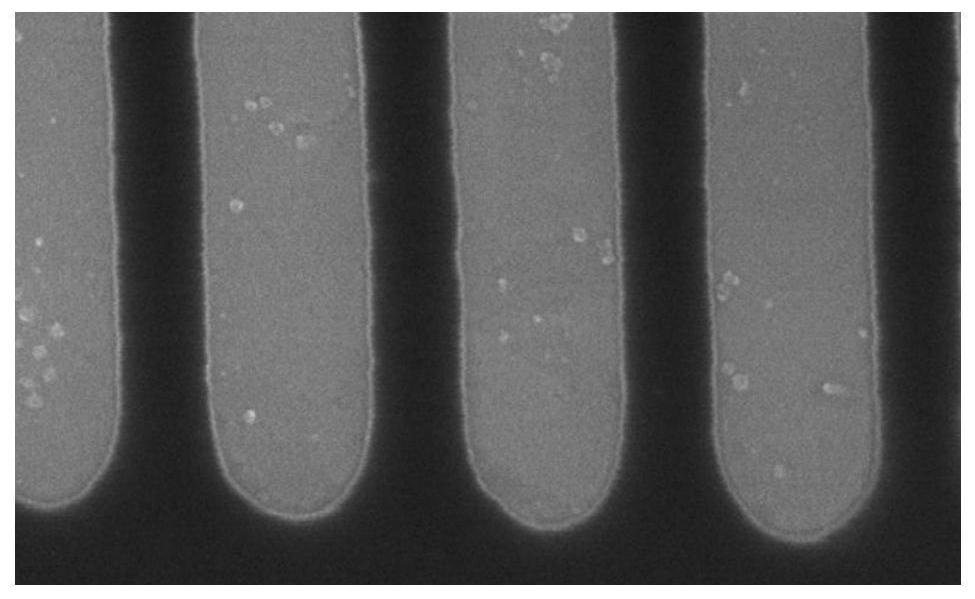

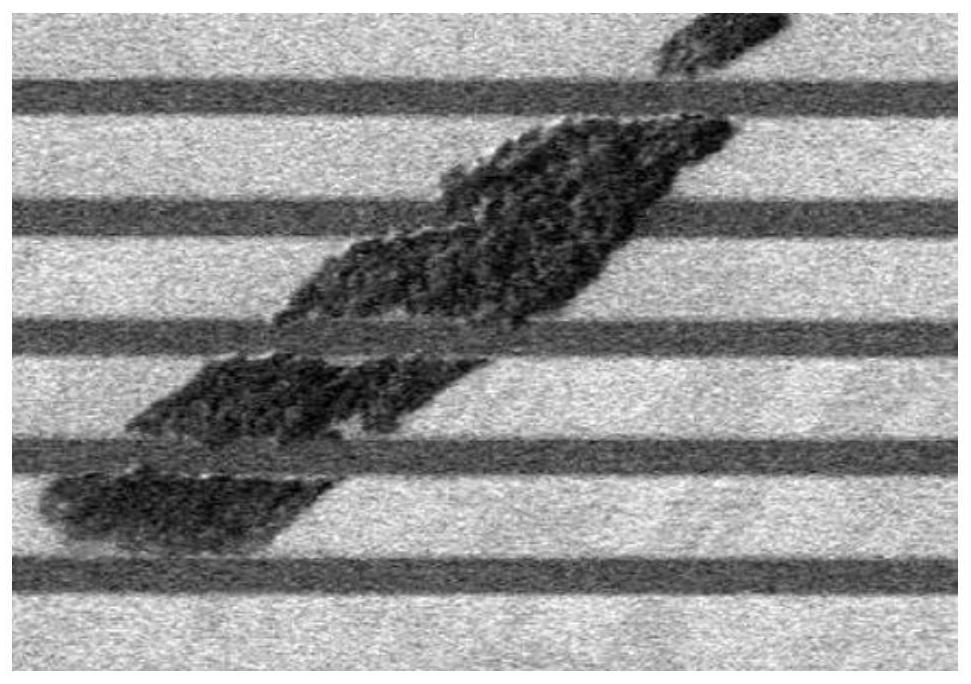

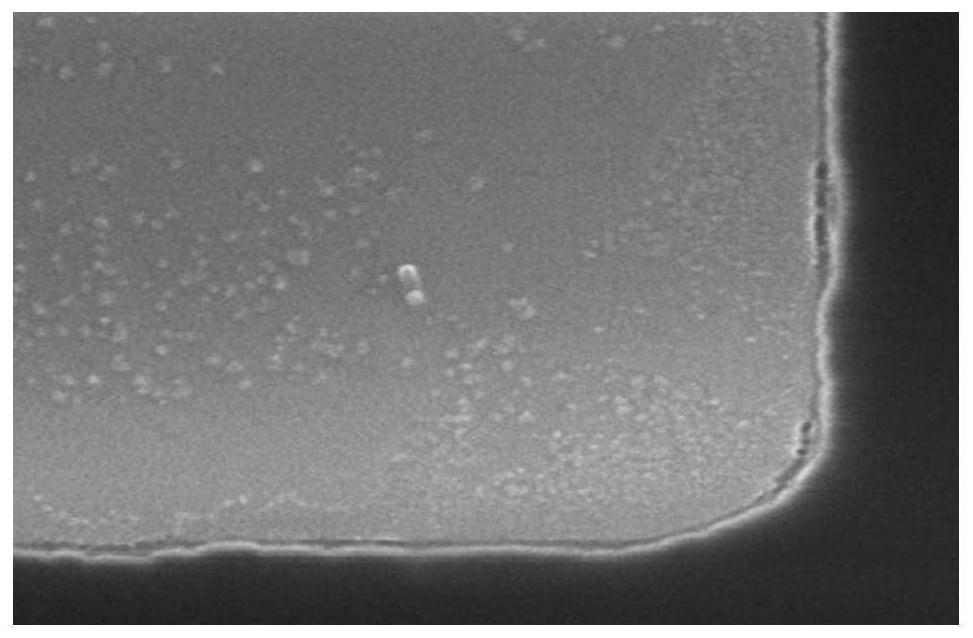

Image

Examples

Embodiment 1

[0060] Add 0.1 parts by weight of PVP, 0.1 parts by weight of acetylene glycol polyether, 0.5 parts by weight of PBTC, 0.3 parts by weight of diethylenetriamine, 5 parts by weight of quaternary ammonium base, and 5 parts by weight of diethylene glycol butyl ether into 89 parts by weight to remove In deionized water, stir evenly to form a transparent solution, then add 10 ppm by weight of modified polysiloxane defoamer and stir evenly, and then use 0.5 weight part of triethanolamine to adjust the pH value of the solution to 12 to prepare a cleaning solution.

Embodiment 2

[0062] Add 0.01 parts by weight of PVP, 0.01 parts by weight of acetylene glycol polyether, 0.1 parts by weight of PBTC, 0.1 parts by weight of diethylenetriamine, 5 parts by weight of quaternary ammonium base, and 5 parts by weight of diethylene glycol butyl ether into 89 parts by weight to remove In deionized water, stir evenly to form a transparent solution, then add 10 ppm by weight of modified polysiloxane defoamer and stir evenly, and then use 0.5 weight part of triethanolamine to adjust the pH value of the solution to 11.0 to prepare a cleaning solution.

Embodiment 3

[0064] Add 0.01 parts by weight of PVP, 0.01 parts by weight of acetylene glycol polyether, 0.5 parts by weight of PBTC, 0.3 parts by weight of diethylenetriamine, 5 parts by weight of quaternary ammonium base, and 5 parts by weight of diethylene glycol butyl ether into 89 parts by weight to remove In deionized water, stir evenly to form a transparent solution, then add 20 ppm by weight of modified polysiloxane defoamer and stir evenly, and then use 0.5 weight part of triethanolamine to adjust the pH value of the solution to 12 to prepare a cleaning solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com