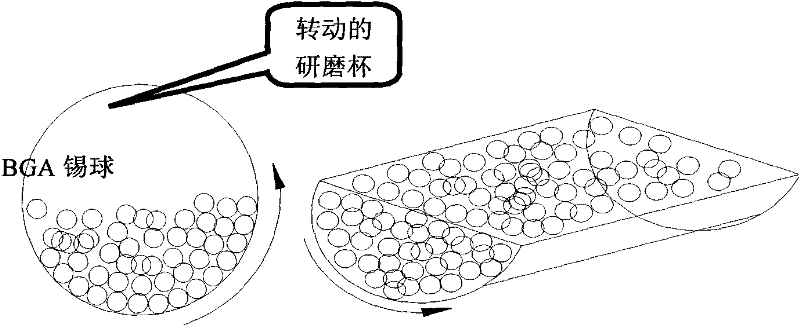

BGA (ball grid array) solder ball surface finish processing method and device

A surface finish and processing equipment technology, applied in the field of solder, to achieve the effect of reducing processing costs, easy maintenance and cleaning, and improving processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

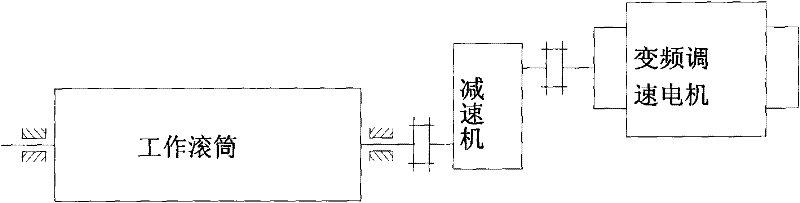

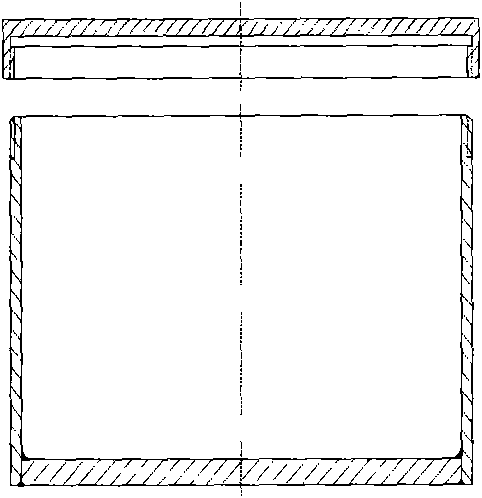

Embodiment Construction

[0029] Such as Figure 1-4 Shown, support 1 is made with two channel steels. The motor 3 is a variable-frequency speed-regulating motor, and is installed on the machine base through the motor bracket 2 . The reducer 5 is a gear reducer, which is installed and fixed on the machine base by the reducer base 17 . Working roller 7 also claims working cup, is installed on the bearing mechanism by the solid shaft at its two ends, and working roller is installed in a straight line on the machine base. The bearing mechanism here is all parts that fix the solid shaft on the axis line and rotate, including tapered roller bearing 9, deep groove ball bearing 10, positioning sleeve 11, bearing housing end cover 12, end cover screw 13, bearing Seat screw 15 and bearing frame 16 etc. A bearing mechanism is provided at both ends of the working roller. The working roller of this example is two. But the working roller that can be installed on the output axis of the same speed reducer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com