One-step synthesis of salicylic acid from phenol and supercritical carbon dioxide

A carbon dioxide and supercritical technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult recovery and recycling of catalysts, complex post-processing, and inability to realize continuous production, etc., to improve selectivity , simple separation, and the effect of simplifying the traditional process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of supported potassium carbonate catalyst:

[0028] In the first step, potassium carbonate is prepared into an aqueous solution with a certain mass fraction; in the second step, the carrier and the binder are uniformly mixed; in the third step, the potassium carbonate solution is added to the mixture of the carrier and the binder, kneaded evenly, and extruded into strips. After the molded catalyst was dried at room temperature for a period of time, it was calcined at 500° C. for 5 hours to obtain a supported potassium carbonate catalyst.

Embodiment 1

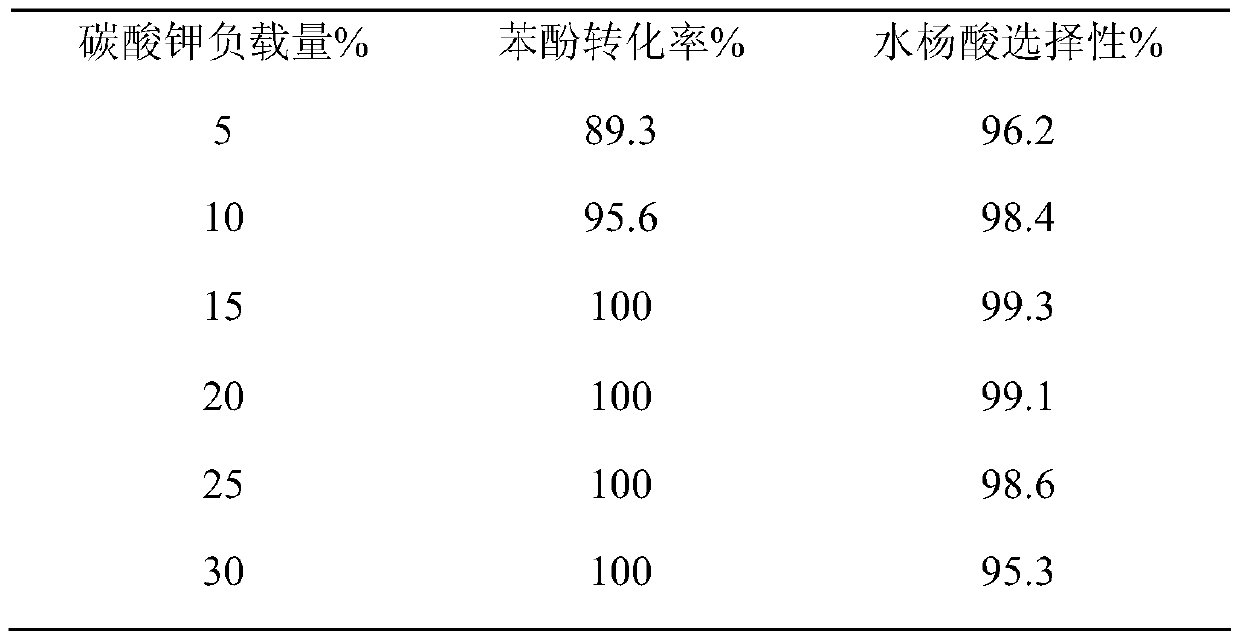

[0030] Catalysts with different loadings of potassium carbonate were prepared with activated carbon as the carrier and aluminum gel as the binder. In a fixed-bed tubular reactor, the temperature is 190°C, the pressure is 8Mpa, and the space velocity is 0.3h -1 Under these conditions, salicylic acid was synthesized from phenol and supercritical carbon dioxide, and the effects of different loadings of potassium carbonate on the conversion of phenol and the selectivity of salicylic acid were investigated. The specific results are shown in Table 1.

[0031] Table 1 Effects of different potassium carbonate loadings on phenol conversion and salicylic acid selectivity

[0032]

Embodiment 2

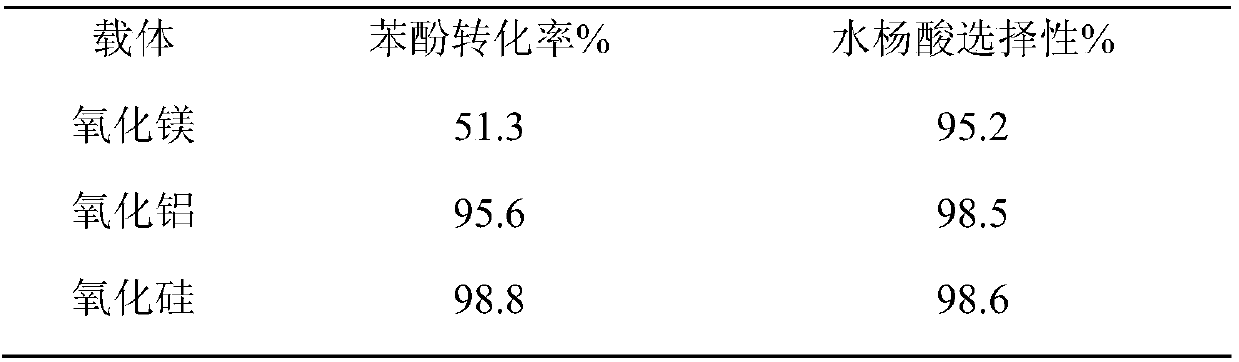

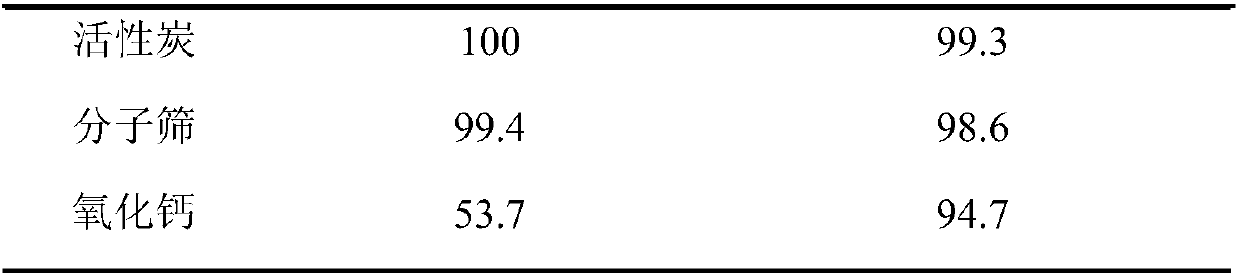

[0034] The load of potassium carbonate was 15%, and the other conditions were the same as in Example 1 to investigate the influence of different carriers on the conversion rate of phenol and the selectivity of salicylic acid. The specific results are shown in Table 2.

[0035] Table 2 Effects of different carriers on the conversion rate of phenol and the selectivity of salicylic acid

[0036]

[0037]

[0038] Salicylic acid synthesis reaction:

[0039] The catalyst prepared by using activated carbon as a carrier with a potassium carbonate load of 15% was packed in a fixed-bed tubular reactor, and phenol and supercritical carbon dioxide passed through the reactor continuously to generate salicylic acid. The effects of different temperatures, pressures and space velocities on the conversion of phenol and the selectivity of salicylic acid were investigated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com