Method for synthesizing propargylamine derivative with different substituent groups at alkyne terminal

A technology of propargylamine and substituents, which is applied in the field of mutual conversion between different propargylamines, can solve the problems of unsuitable modification of end group of internal alkyne-type propargylamine, and achieves easy commercial purchase or preparation, high yield and moderate price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

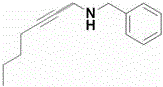

[0030] The preparation of N-benzyl-2-heptynylamine, structural formula is as follows:

[0031]

[0032] Under nitrogen protection, add raw material 1-hexyne (1.5mmol), N-benzyl-2-butynylamine (0.3mmol) and catalyst Lu[N(SiMe 3 ) 2 ] 3 (1mol%), xylene (2ml), reacted at 150°C for 48h, and the isolated yield of the product was 70%.

[0033] 1 HNMR (CDCl 3 ,400MHz,ppm):δ7.35-7.30(m,4H),7.27-7.25(m,1H),3.86(s,2H),3.40(t, J =2.12Hz,2H),2.23-2.19(m,2H),1.62(br,1H),1.52-1.40(m,4H),0.92(t, J =7.21Hz, 3H).

Embodiment 2

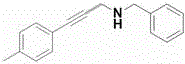

[0035] The preparation of N-benzyl-5-phenyl-2-pentynylamine, structural formula is as follows:

[0036]

[0037] Under nitrogen protection, add raw material phenylethylacetylene (1.5mmol), N-benzyl-2-butynylamine (0.3mmol) and catalyst Lu[N(SiMe 3 ) 2 ] 3 (10mol%), toluene (2ml), reacted at 130°C for 12h, and the isolated yield of the product was 95%.

[0038] 1 HNMR (CDCl 3 ,400MHz,ppm):δ7.31-7.20(m,10H),3.80(s,2H),3.38(t, J =2.14Hz,2H),2.83(t, J =7.51Hz, 2H), 2.52-2.49(m, 2H), 1.47(br, 1H).

Embodiment 3

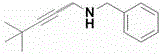

[0040] The preparation of N-benzyl-4,4-dimethyl-2-pentynylamine, the structural formula is as follows:

[0041]

[0042] Under the protection of nitrogen, the raw material tert-butylacetylene (1.5mmol), N-benzyl-2-butynylamine (0.3mmol) and catalyst Sc[N(SiMe 3 ) 2 ] 3 (10mol%), toluene (2ml), reacted at 130°C for 12h, and the isolated yield of the product was 80%.

[0043] 1 HNMR (400MHz, CDCl 3 )δ7.34-7.32 (m, 4H), 7.27-7.24 (m, 1H), 3.86 (s, 2H), 3.39 (s, 2H), 1.65 (br, 1H), 1.24 (s, 9H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com