A kind of filler composition and its application

A composition and mixture technology, which is applied in the field of copper clad laminates, can solve the problems of poor dispersion, low adhesion between adhesive sheets, poor thermal reliability of copper clad laminates, etc., and achieve high dispersion and improved layer quality. Inter-adhesion, the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

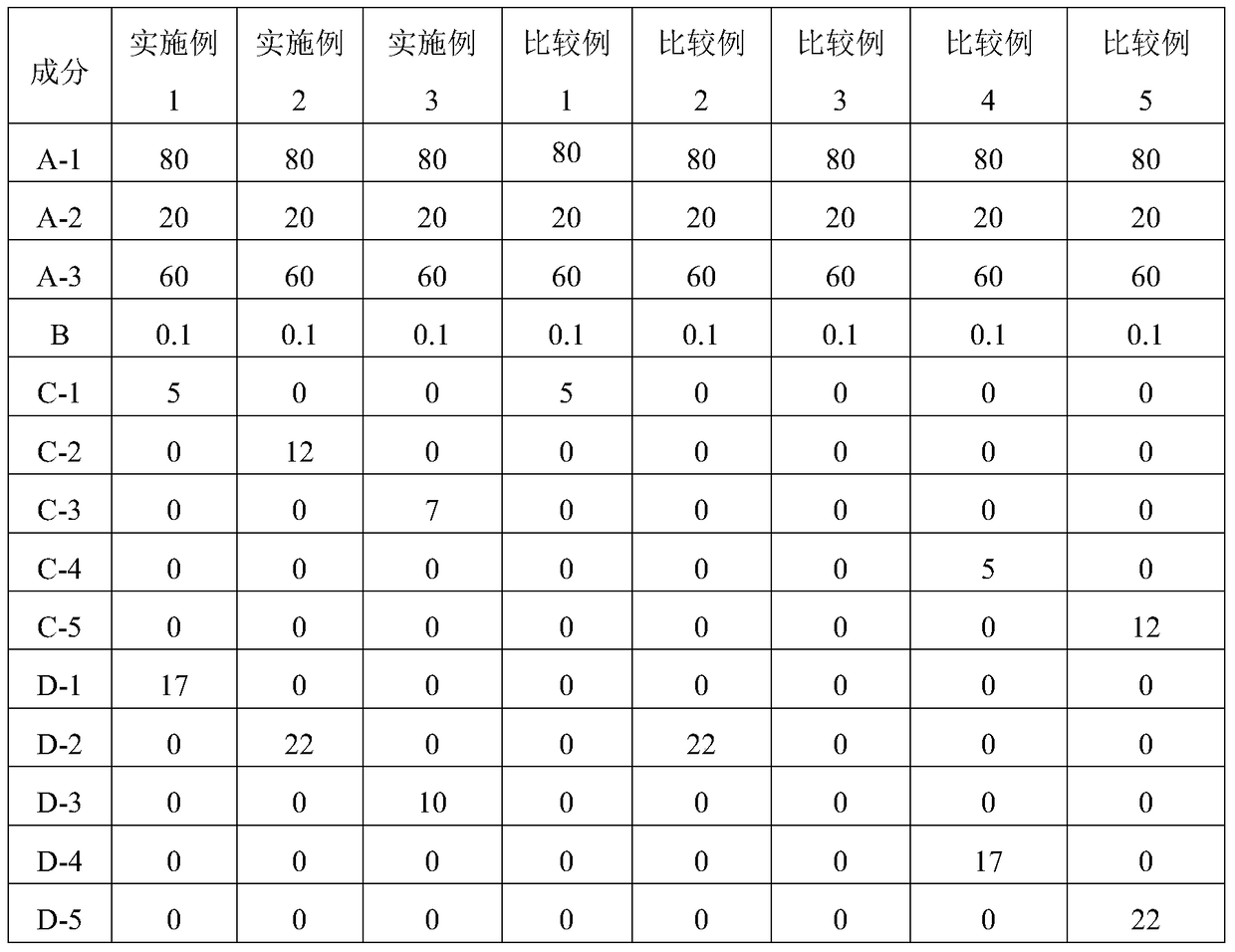

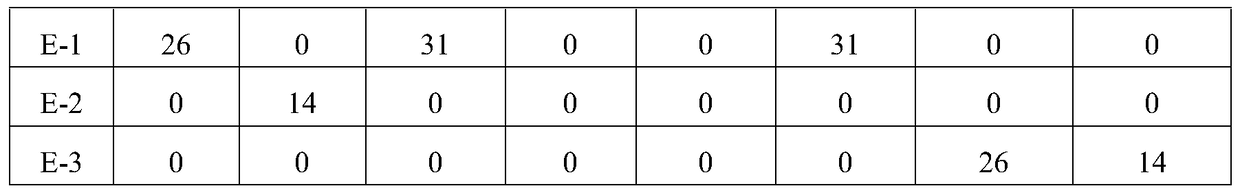

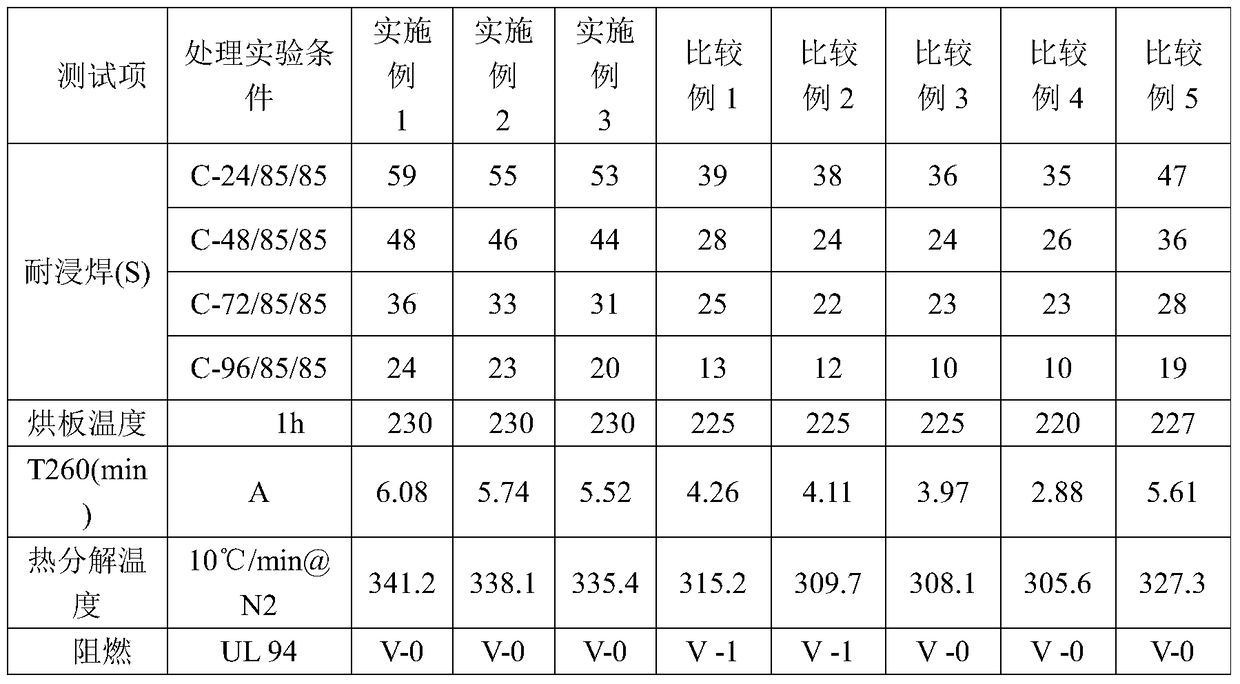

[0022] The manufacturing methods of the copper clad laminates of Examples 1-3 and Comparative Examples 1-5: the specific parameters are shown in Table 1.

[0023] Put low expansion coefficient fillers, thermal conductivity fillers, halogen-free high thermal decomposition temperature flame retardants, thermosetting resins, and curing accelerators into a container and stir evenly to prepare low expansion coefficient fillers, thermal conductivity fillers, and halogen-free high thermal decomposition temperature flame retardants. The total amount of the agent is a composition with a thermosetting resin content of 30wt%, and a solvent is used to adjust the solid content of the solution to 70% to make a glue solution, thereby obtaining the filler composition of the present invention.

[0024] Use wood pulp paper to impregnate the filler composition, dry in an oven to obtain a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com