Curable composition for sealing optical semiconductor and optical semiconductor device using the same

A curable composition, optical semiconductor technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of low gas permeability, brightness reduction, etc., to improve reliability, improve yield and production property, the effect of suppressing the reduction of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

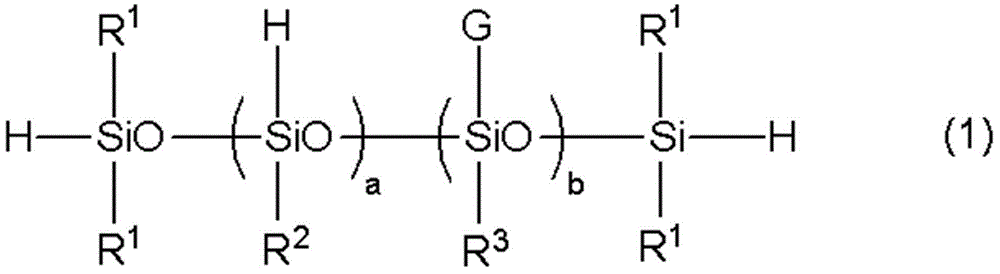

[0218] To 100 parts by mass of a straight-chain polyfluoro compound represented by the following formula (21) (viscosity 10,900 mPa·s, vinyl content 0.0123 mol / 100 g), sequentially add platinum-divinyltetramethyldisilazine 0.15 parts by mass of a toluene solution (platinum concentration: 0.5% by mass) of an oxane complex, 0.20 parts by mass of a 60% toluene solution of 1-ethynyl-1-hydroxycyclohexane, and an organic compound represented by the following formula (22): 2.87 parts by mass of hydrogen polysiloxane (SiH group equivalent: 0.00428 mol / g), 2.5 parts by mass of organopolysiloxane represented by the following formula (23), 0.50 parts by mass of carboxylic anhydride represented by the following formula (24) parts by mass, and mix until uniform. Then, a defoaming operation was performed to prepare a composition.

[0219]

[0220] In formula (21), h' and i' are integers of 1 or more, and the average value of h'+i' is 90.

[0221]

[0222] In formula (22), j' and k' ...

Embodiment 2

[0226] To 100 parts by mass of the straight-chain polyfluorinated compound represented by the above formula (21), 0.15 oz. Parts by mass, 0.20 parts by mass of a 60% toluene solution of 1-ethynyl-1-hydroxycyclohexane, 1.93 parts by mass of organohydrogenpolysiloxane (SiH group equivalent: 0.00636 mol / g) represented by the following formula (25) parts, 2.5 parts by mass of organopolysiloxane represented by the following formula (26), and 0.50 parts by mass of the carboxylic anhydride represented by the above formula (24), and mixed until uniform. Then, a defoaming operation was performed to prepare a composition.

[0227]

[0228] In formula (25), l' and m' are integers of 1 or more, and the average value of l' is 11, and the average value of m' is 3.

[0229]

Embodiment 3

[0231] To 100 parts by mass of a straight-chain polyfluoro compound represented by the following formula (27) (viscosity 4,010 mPa·s, vinyl content 0.0299 mol / 100 g), sequentially add platinum-divinyltetramethyldisilazine 0.15 parts by mass of a toluene solution (platinum concentration: 0.5% by mass) of an oxane complex, 0.20 parts by mass of a 60% toluene solution of 1-ethynyl-1-hydroxycyclohexane, and an organic compound represented by the following formula (28): 5.99 parts by mass of hydrogen polysiloxane (SiH group equivalent: 0.00499 mol / g), 2.0 parts by mass of organopolysiloxane represented by the following formula (29), 0.50 parts by mass of carboxylic acid anhydride represented by the following formula (30) parts by mass, and mix until uniform. Then, a defoaming operation was performed to prepare a composition.

[0232]

[0233] In formula (27), n' and o' are integers of 1 or more, and the average value of n'+o' is 35.

[0234]

[0235] In formula (28), p' and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com