Novel high-efficiency wet-surface antibacterial paint, and preparation method thereof

An antibacterial coating and high-efficiency technology, used in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as poor antibacterial effect, and achieve the effect of easy implementation, reasonable components, and easy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

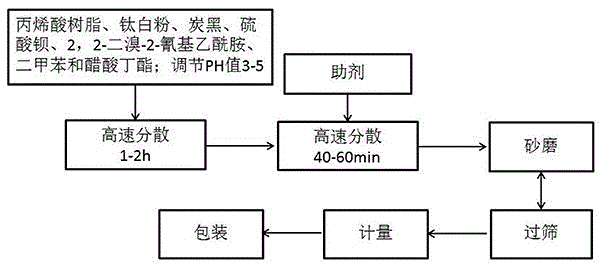

[0038] A kind of preparation method of novel high-efficiency wet surface antibacterial coating, such as figure 1 shown, including the following steps:

[0039] (1) Take 45 parts of acrylic resin, 18 parts of titanium dioxide, 0.4 parts of carbon black, 14 parts of barium sulfate, 4 parts of 2,2-dibromo-2-cyanoacetamide (purity ≥ 99.2%), xylene (purity ≥99%) 10 parts and 2 parts of butyl acetate (purity ≥99.5%) are added to the dispersion tank, and the pH value is adjusted with dilute hydrochloric acid to make the pH value reach 3; stir at 1800r / min at high speed for 1h;

[0040] (2) Add 5 parts of additives and continue to stir at a high speed of 1800r / min for 40 minutes; wherein, the additives are calculated by weight components, including the following components: 1 part of dispersant, 1 part of leveling agent and 0.2 parts of defoamer share;

[0041] (3) Put the material in step (2) into a sand mill for grinding for 1 hour, and pass through a 100-mesh vibrating screen;

...

Embodiment 2

[0045] A kind of preparation method of novel high-efficiency wet surface antibacterial coating, such as figure 1 shown, including the following steps:

[0046] (1) Take 70 parts of acrylic resin, 32 parts of titanium dioxide, 0.8 parts of carbon black, 30 parts of barium sulfate, 5 parts of 2,2-dibromo-2-cyanoacetamide (purity ≥ 99.2%), xylene (purity ≥99%) 20 parts and butyl acetate (purity ≥99.5%) 8 parts into the dispersion tank, use dilute hydrochloric acid to adjust the pH value to 5; stir at 2200r / min at high speed for 2h;

[0047] (2) Add 10 parts of additives and continue to stir at 2200r / min for 60 minutes; wherein, the additives are calculated by weight components, including the following components: 4 parts of dispersant, 4 parts of leveling agent and 2 parts of defoamer share;

[0048] (3) Put the material in step (2) into a sand mill for grinding for 2 hours, and pass through a 150-mesh vibrating screen;

[0049] (4) Grind the unsieved material in step (3) for ...

Embodiment 3

[0052] A kind of preparation method of novel high-efficiency wet surface antibacterial coating, such as figure 1 shown, including the following steps:

[0053] (1) Take 60 parts of acrylic resin, 25 parts of titanium dioxide, 0.5 parts of carbon black, 20 parts of barium sulfate, 4.5 parts of 2,2-dibromo-2-cyanoacetamide (purity ≥ 99.2%), xylene (purity ≥99%) 15 parts and butyl acetate (purity ≥99.5%) 6 parts into the dispersion tank, use dilute hydrochloric acid to adjust the pH value to 4; stir at 2000r / min high speed for 1.5h;

[0054] (2) Add 8 parts of additives and continue to stir at a high speed of 2000r / min for 50 minutes; wherein, the additives are calculated by weight components, including the following components: 3 parts of dispersant, 3 parts of leveling agent and 1 part of defoamer share;

[0055] (3) Put the materials in step (2) into a sand mill for grinding for 1.5 hours, and pass through a 120-mesh vibrating screen;

[0056] (4) Grind the unsieved material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com