Rare-earth-cerium-copper-zinc-alloy electroplating solution and electroplating method thereof

A zinc alloy and rare earth cerium technology, which is applied to rare earth cerium-copper-zinc alloy electroplating solution and its electroplating field, can solve the problems of corrosion resistance and lack of color and luster, and achieve beautiful color and luster, excellent compactness and corrosion resistance, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

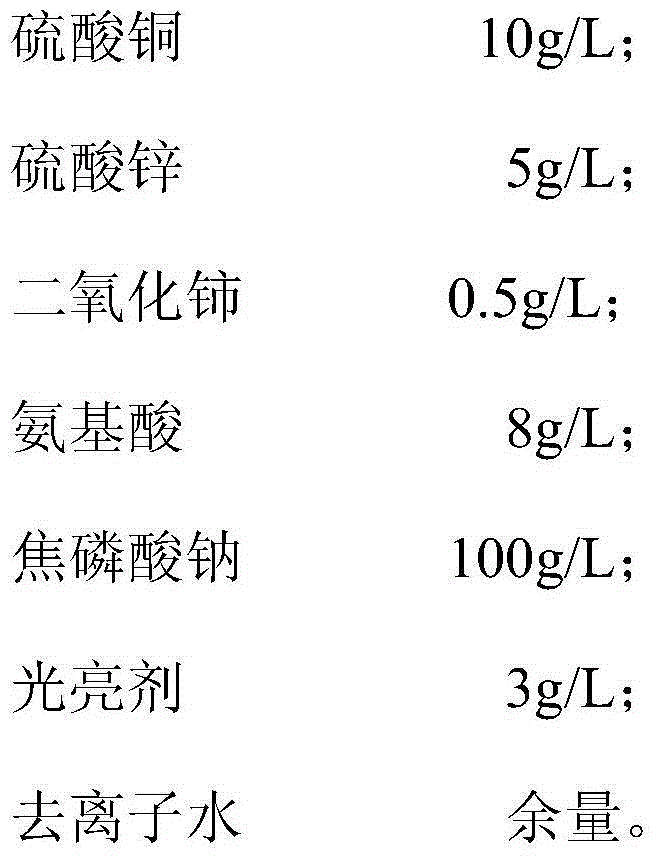

[0020] Embodiment 1: the rare earth cerium-copper-zinc alloy electroplating solution of the present embodiment comprises the following components:

[0021]

[0022] Use this rare earth cerium-copper-zinc alloy plating solution electroplating method as follows:

[0023] Put 100g of sodium pyrophosphate into deionized water to dissolve and form a solution, add 8g of amino acid, 10g of copper sulfate, and 5g of zinc sulfate to the solution, heat and stir to dissolve to form a mixed solution, and continue to add 0.5g of cerium oxide to the mixed solution and brightener 3g, stir to dissolve, add the remaining amount of deionized water to a total volume of 1L to obtain a rare earth cerium-copper-zinc alloy electroplating solution, adjust the pH value to 9-13 with sodium hydroxide;

[0024] Use a carbon electrode as the anode, and make the negative electrode after the workpiece is polished, degreased, and dipped in dilute acid. The area ratio of the cathode to the anode is 1:1. 2...

Embodiment 2

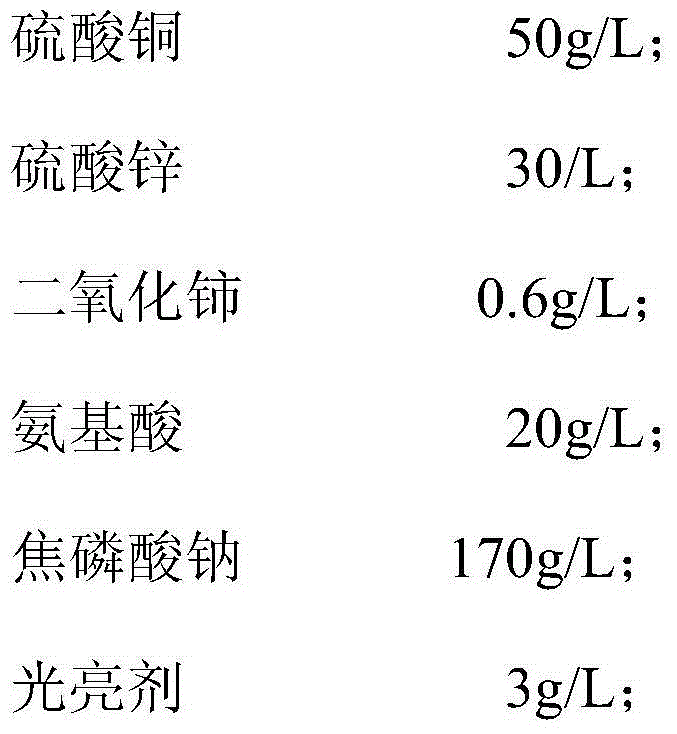

[0025] Embodiment 2: the rare earth cerium-copper-zinc alloy electroplating solution of the present embodiment comprises the following components:

[0026]

[0027]

[0028] Use this rare earth cerium-copper-zinc alloy plating solution electroplating method as follows:

[0029] Put 170g of sodium pyrophosphate into deionized water to dissolve to form a solution, add 20g of amino acid, 50g of copper sulfate, and 30g of zinc sulfate to the solution, heat and stir to dissolve to form a mixed solution, and continue to add 0.6g of cerium oxide to the mixed solution and brightener 3g, stir to dissolve, add the remaining amount of deionized water to a total volume of 1L to obtain a rare earth cerium-copper-zinc alloy electroplating solution, adjust the pH value to 9-13 with sodium hydroxide;

[0030] Use a carbon electrode as the anode, and make the negative electrode after the workpiece is polished, degreased, and dipped in dilute acid. The area ratio of the cathode to the ano...

Embodiment 3

[0031] Embodiment 3: the rare earth cerium-copper-zinc alloy electroplating solution of the present embodiment comprises the following components:

[0032]

[0033] Use this rare earth cerium-copper-zinc alloy plating solution electroplating method as follows:

[0034] Put 200g of sodium pyrophosphate into deionized water to dissolve and form a solution, add 40g of amino acid, 80g of copper sulfate, and 60g of zinc sulfate to the solution, heat and stir to dissolve and make a mixed solution, and continue to add cerium dioxide 1g and Brightener 8g, stir to dissolve, add the remaining amount of deionized water to a total volume of 1L to obtain a rare earth cerium-copper-zinc alloy electroplating solution, adjust the pH value to 9-13 with sodium hydroxide;

[0035] Use a carbon electrode as the anode, and make the negative electrode after the workpiece is polished, degreased, and dipped in dilute acid. The area ratio of the cathode to the anode is 1:1. 2 Electroplating is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com