Device for measuring resistivity and seebeck coefficient and usage method

A technique for measuring Seebeck coefficient and measuring resistance, which is applied in measuring devices, measuring resistance/reactance/impedance, and measuring electrical variables, etc. It can solve the problems of objective evaluation affecting product performance, low measurement accuracy, and poor repeatability of measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

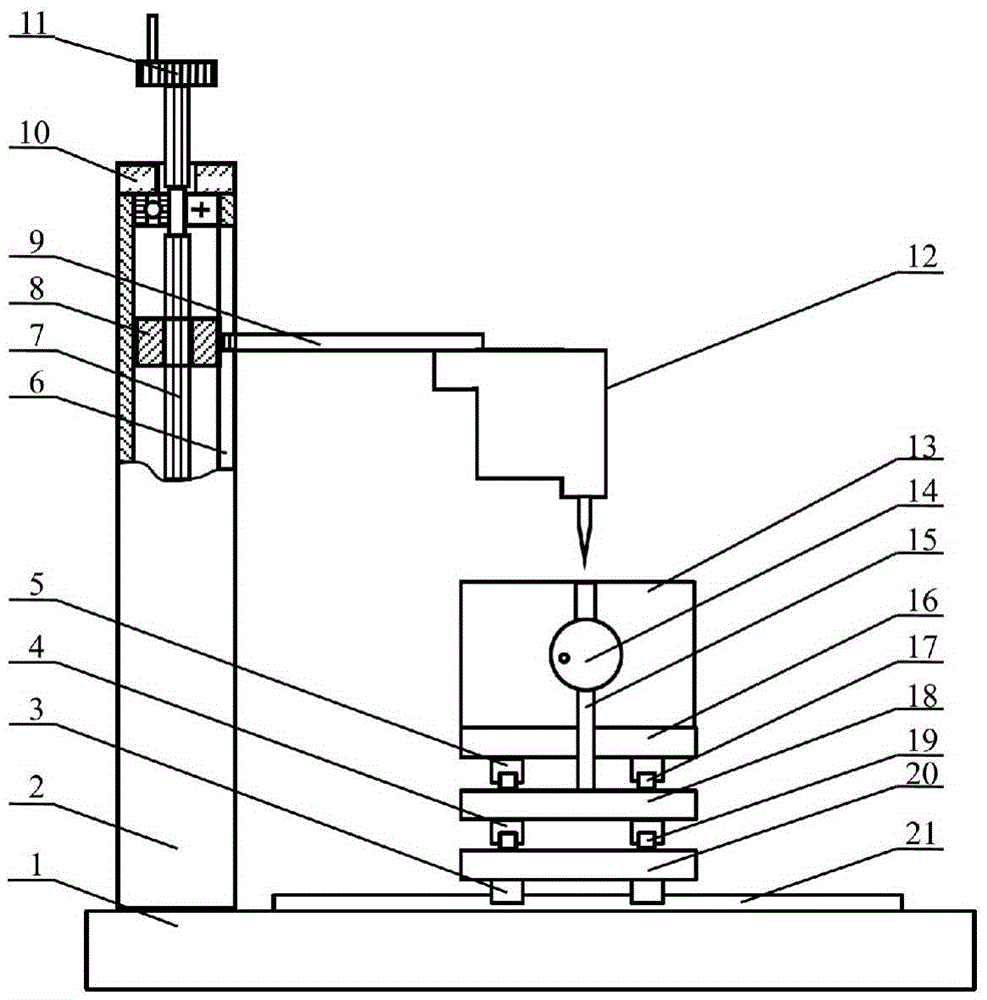

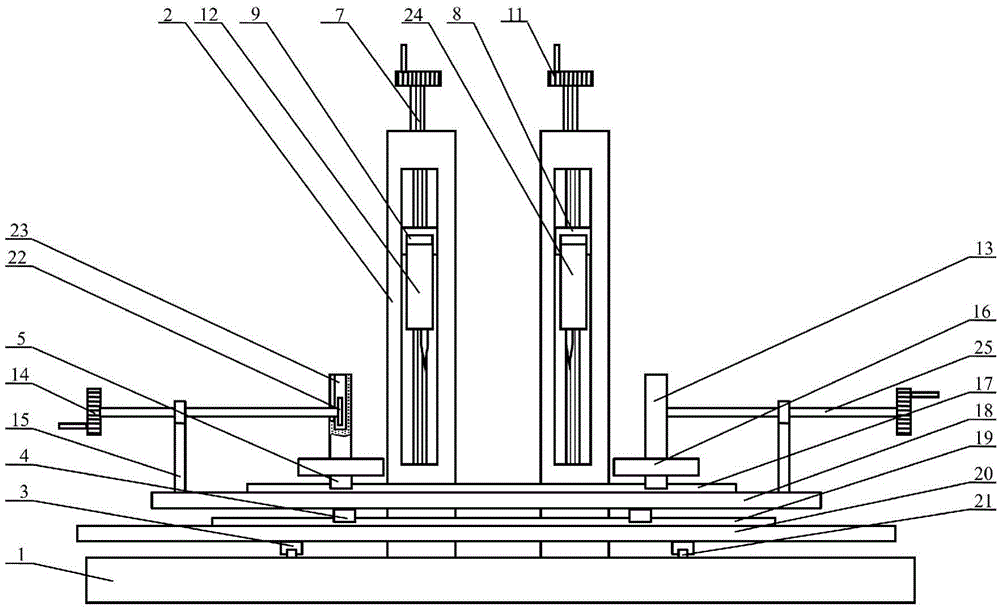

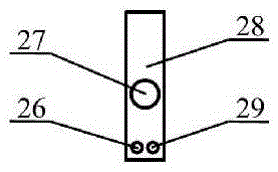

[0063] A device for measuring resistivity and Seebeck coefficient. Such as figure 1 with figure 2 As shown, the device consists of a lifting system, a horizontal moving system and a measuring system. For the convenience of description, this embodiment uses figure 2 the left side of is the left side, figure 1 The left side is the rear side.

[0064] The structure of the lifting system is as follows: Figure 1 ~ Figure 4 Shown:

[0065] Such as figure 1 with figure 2 Shown: two square steel pipes 2 are symmetrically fixed on the rear side of the upper surface of base plate 1, and lower bearing, nut type slide block 8, upper bearing and end cover 10 are successively housed in square steel pipe 2 from bottom to top. The lower end of vertical screw mandrel 7 is installed in the lower bearing, and the middle part of vertical screw mandrel 7 is threadedly connected with nut type slide block 8, and the upper end of vertical screw mandrel 7 passes through upper bearing and e...

Embodiment 2

[0110] A device for measuring resistivity and Seebeck coefficient. The device described in this embodiment is the same as that in Embodiment 1.

[0111] Method for measuring resistivity and Seebeck coefficient using the device.

[0112] The sample 36 to be tested in this embodiment is N-type Bi 2 Te 2.7 Se 0.3 Sample, the sample to be tested 36 is a cross-sectional size of 20 × 20mm 2 and a cuboid with a longitudinal dimension of 100mm.

[0113] The measuring method of resistivity described in the present embodiment is:

[0114] Step 1.1, such as Figure 7 As shown, first a surface to be tested of the sample to be tested 36 is divided into 10 regions to be tested; then the surface to be tested of the sample to be tested 36 is placed upwards, placed between the clamping electrodes 13 along the longitudinal direction, and rotated Move the lower hand wheels 14 on both sides to clamp the sample 36 to be tested.

[0115] Step 1.2 to step 1.4 are the same as step 1.2 to step...

Embodiment 3

[0145] A device for measuring resistivity and Seebeck coefficient. The device described in this embodiment is the same as that in Embodiment 1.

[0146] Method for measuring resistivity and Seebeck coefficient using the device.

[0147] The sample 36 to be tested in this embodiment is P-type Bi 0.5 Sb 1.5 Te 3 A test piece, which is a cylinder with a diameter of 40 mm and a longitudinal dimension of 400 mm.

[0148] The measuring method of resistivity described in the present embodiment is:

[0149] Step 1.1, such as Figure 8 As shown, first a surface to be tested of the sample to be tested 36 is divided into 20 regions to be tested; then the surface to be tested of the sample to be tested 36 faces up, and is placed between the clamping electrodes 13 along the longitudinal direction, and rotated Move the lower hand wheels 14 on both sides to clamp the sample 36 to be tested.

[0150] Step 1.2 to step 1.4 are the same as step 1.2 to step 1.4 in Example 1.

[0151] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com