F19mm large relative aperture mechanical passive type athermalized lens and compensation adjusting method

A relative aperture, passive technology, used in installation, optics, instruments, etc., can solve the problems of reducing the imaging quality of the optical system, the optimal image plane deviation of the optical system, and the complex use environment of the infrared lens, and achieve good sealing performance and ensure sealing. performance, the effect of increasing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

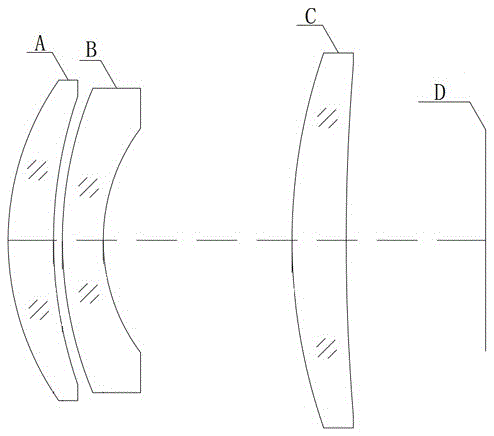

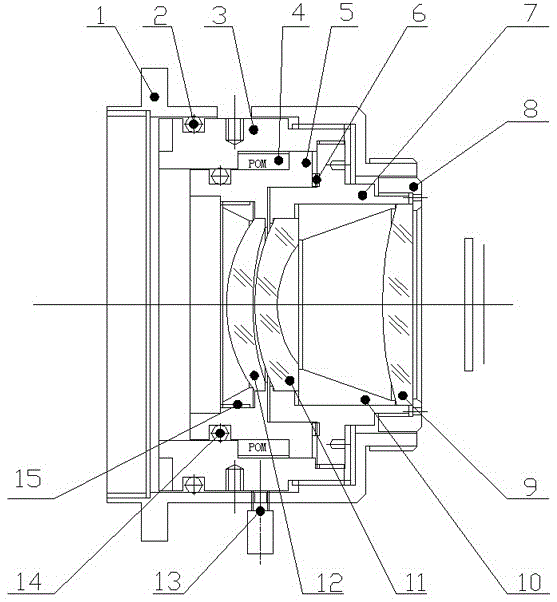

[0023] Such as Figure 1~2 As shown, the f19mm large relative aperture mechanical passive athermalized lens includes an optical system and a mechanical structure. In the optical system of the lens, a positive lens A, a negative lens B, and a positive lens C are sequentially arranged along the incident direction of light. The mechanical structure includes the front group 5 of the main lens barrel and the rear group 7 of the main lens barrel. Between the front group 5 of the main lens barrel and the rear group 7 of the main lens barrel, there is a device for positioning and ensuring the distance, which can be realized by the principle of thermal expansion and contraction. Telescopic telescopic mechanism group.

[0024] In this embodiment, the air space between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com