Super-continuum spectrum optical fiber laser output apparatus and laser system

An output device and fiber laser technology, which is applied in the field of laser optoelectronics, can solve the problems of excessive power density, thermal damage, and damage on the output end face of the fiber, and achieve the effect of reducing the optical power density, high power, and increasing the end face damage threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

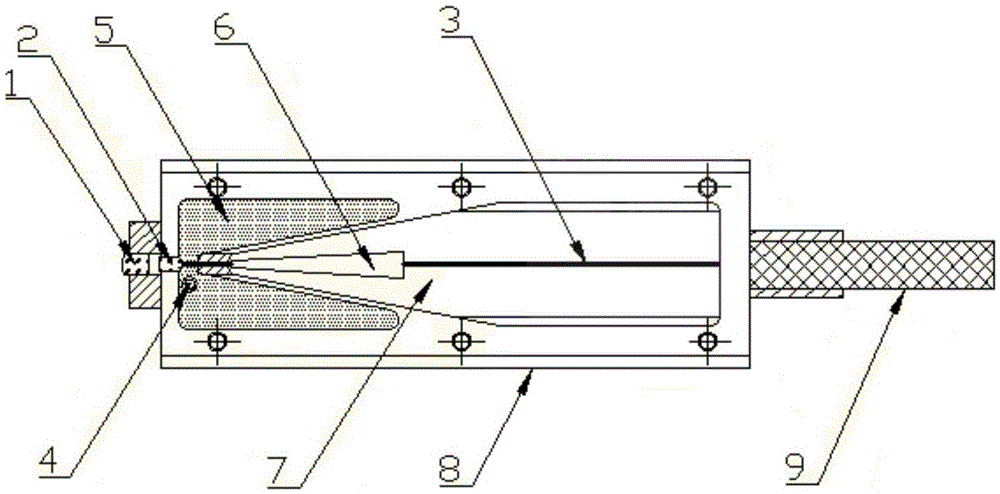

[0019] figure 1 A schematic structural view of the supercontinuum fiber laser output device of the present invention is shown.

[0020] refer to figure 1 , the supercontinuum fiber laser output device of an embodiment of the present invention, specifically includes:

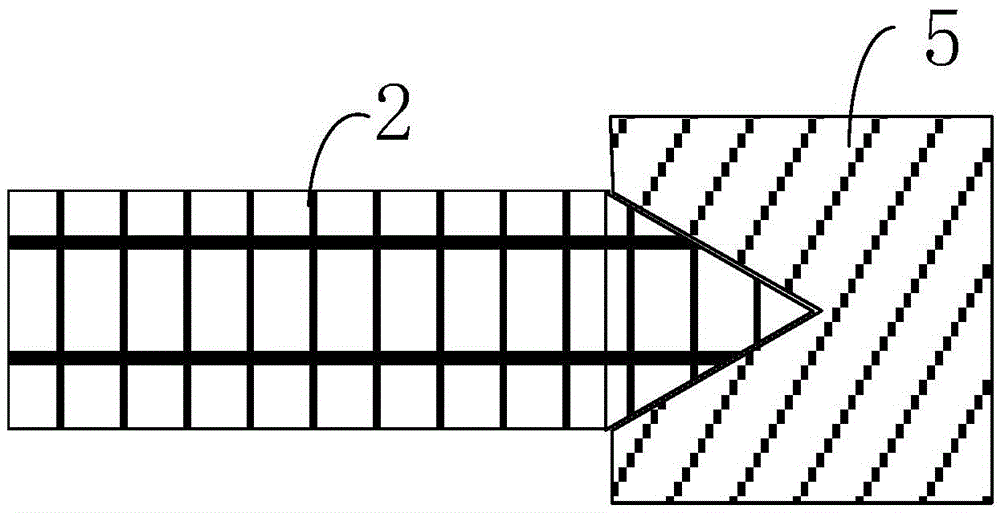

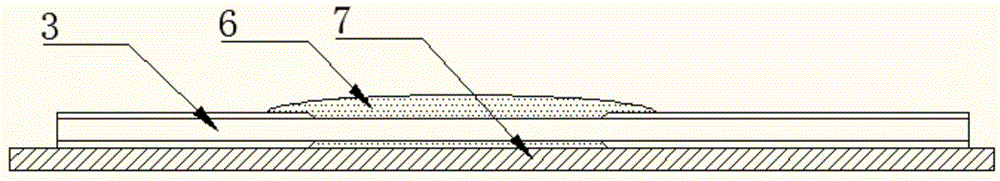

[0021] Laser transmission module, return light processor 5, light stripper 6, heat processor 7 and package module 8, wherein, laser transmission module comprises the transmission optical fiber 3, output end cap 2 and beam focusing and collimating part 1 connected in sequence, and setting A photodetector 4 on the side of the output end cap close to the transmission fiber.

[0022] like fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com