Method for preparing high-bulk-density flavor nucleotides disodium mixed crystal

A technology of disodium nucleotide and density, which is applied in food science and other directions, can solve the problems of not being able to meet the preparation requirements of high-quality umami agents, not strictly controlling crystallization nucleation, and low product bulk density, and achieve a solvent system. Green and friendly, the effect of solving the difficulty of GMP crystallization and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Take 7.11 g of crude disodium inosinate and 7.89 g of amorphous disodium guanylate, add them to 250 ml of pure water, keep the solution at 25°C, start stirring at 100 rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 7.5.

[0049] 2) Adjust the stirring to 200rpm, add 75ml of absolute ethanol (V=30%V) within 30min 水 ), after mixing evenly, add 0.075 g of I+G seed crystal (w=0.5% I+G crude product), and grow the crystal for 20 minutes.

[0050] 3) Continue to add 425ml of ethanol dropwise, the time for adding the first 50ml is 2h, and the time for adding the last 375ml is 1h.

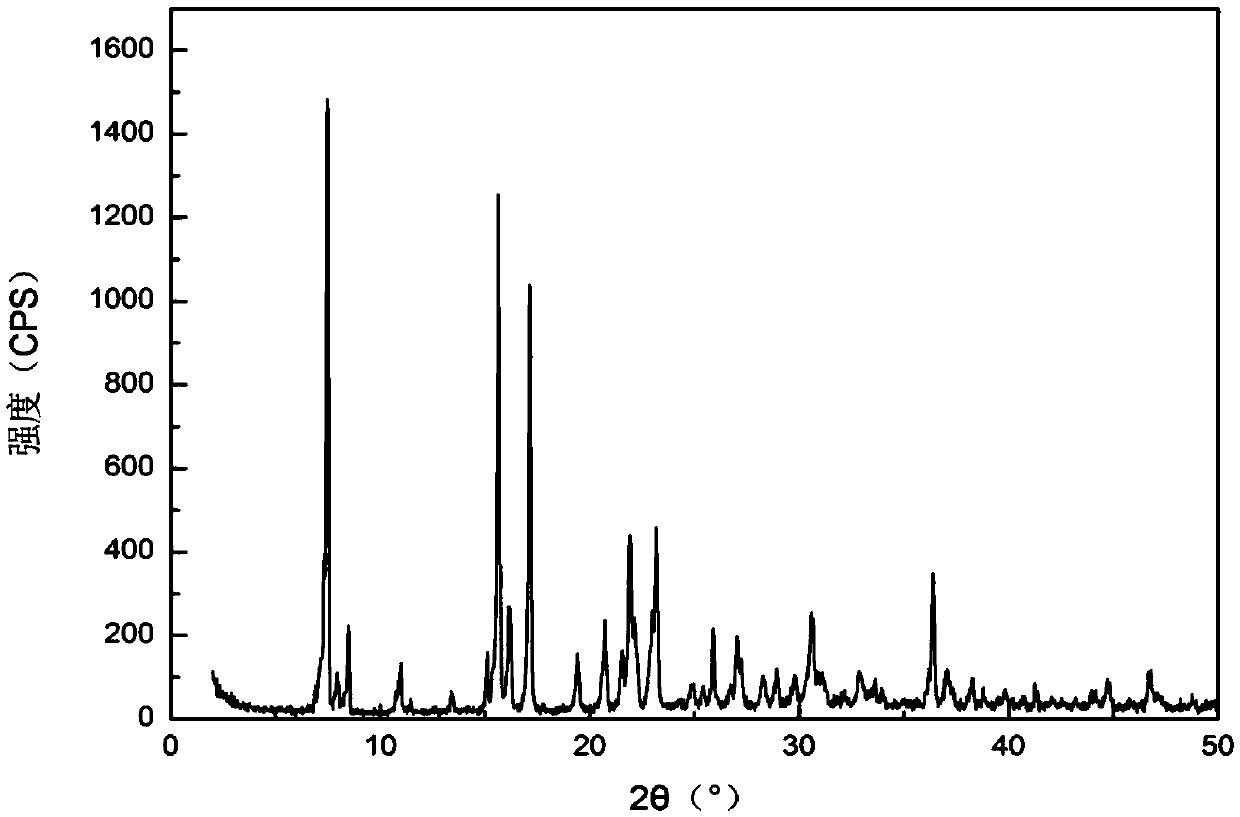

[0051] 4) Suction filtration, washing the filter cake with 95% ethanol, and drying at normal temperature and pressure for 1 hour. 12.2 g of the I+G mixed crystal product was obtained with a yield of 80.9%. After measurement, the bulk density of the product is 0.81g / ml. The detection result of the Malvern particle size analyzer is d(50)=360 ...

Embodiment 2

[0054] 1) Take 30.45g of crude disodium inosinate and 32.05g of crude disodium guanylate, add them to 250ml of pure water, keep the solution at 45°C, start stirring at 600rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 8.5.

[0055] 2) Adjust and stir at 400rpm, add 25ml of anhydrous methanol (V=10%V) within 30min 水 ), after mixing evenly, add 6.25 g of I+G seed crystals (w=0.5% I+G crude product), and grow the crystals for 30 minutes.

[0056] 3) Continue to add 225ml of methanol dropwise, the time for adding the first 150ml is 3h, and the time for adding the last 75ml is 1h.

[0057] 4) Suction filtration, the filter cake was washed with 95% ethanol, and dried at normal temperature and pressure for 3 hours to obtain 64.76 g of I+G mixed crystal product with a yield of 94.2%. After measurement, the bulk density of the product is 0.77g / ml. The detection result of the Malvern particle size analyzer was d(50)=244 μm.

[00...

Embodiment 3

[0060] 1) Take 18.75g of crude disodium inosinate and 18.75g of crude disodium guanylate, add them into 250ml of pure water, keep the solution at 35°C, start stirring at 300rpm to dissolve it. Solid sodium hydroxide was added to adjust the pH of the aqueous I+G solution to 8.0.

[0061] 2) Add 65ml of absolute ethanol (V=26%V) within 30min 水 ), after mixing evenly, add 2.0 g of I+G seed crystals (w=5.3% I+G crude product), and grow the crystals for 30 minutes.

[0062] 3) Continue to add 255ml of ethanol dropwise, the time for adding the first 65ml is 2h, and the time for adding the last 115ml is 2h.

[0063] 4) Suction filtration, the filter cake was washed with 95% ethanol, and dried at normal temperature and pressure for 1 h to obtain 37.95 g of I+G mixed crystal product with a yield of 96.1%. After measurement, the bulk density of the product is 0.86g / ml. The detection result of the Malvern particle size analyzer was d(50)=419 μm.

[0064] The product appearance obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com