Sleeve type lumbar puncture needle and use method thereof

A lumbar puncture and sleeve-type technology, applied in the direction of puncture needle, trocar, application, etc., can solve life-threatening, inaccurate pressure measurement, cerebrospinal fluid ejection and other problems, and achieve long service life, precise control and precise adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

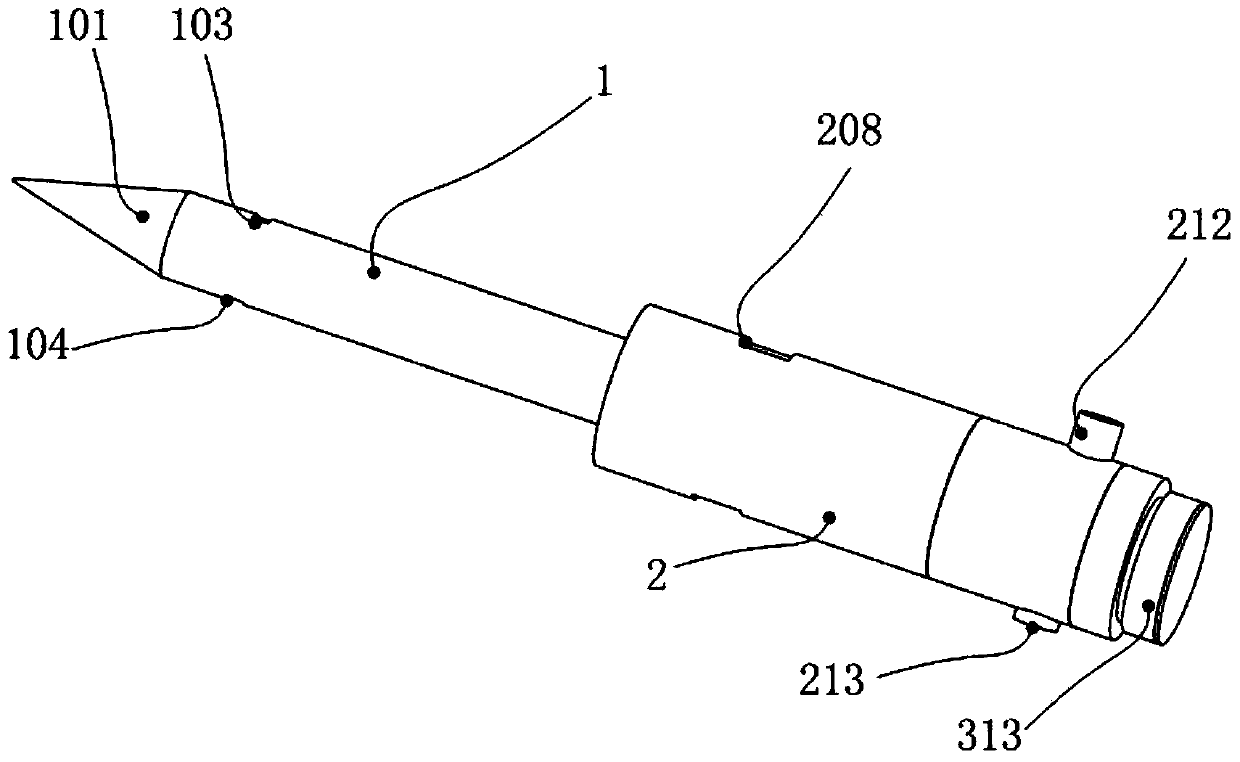

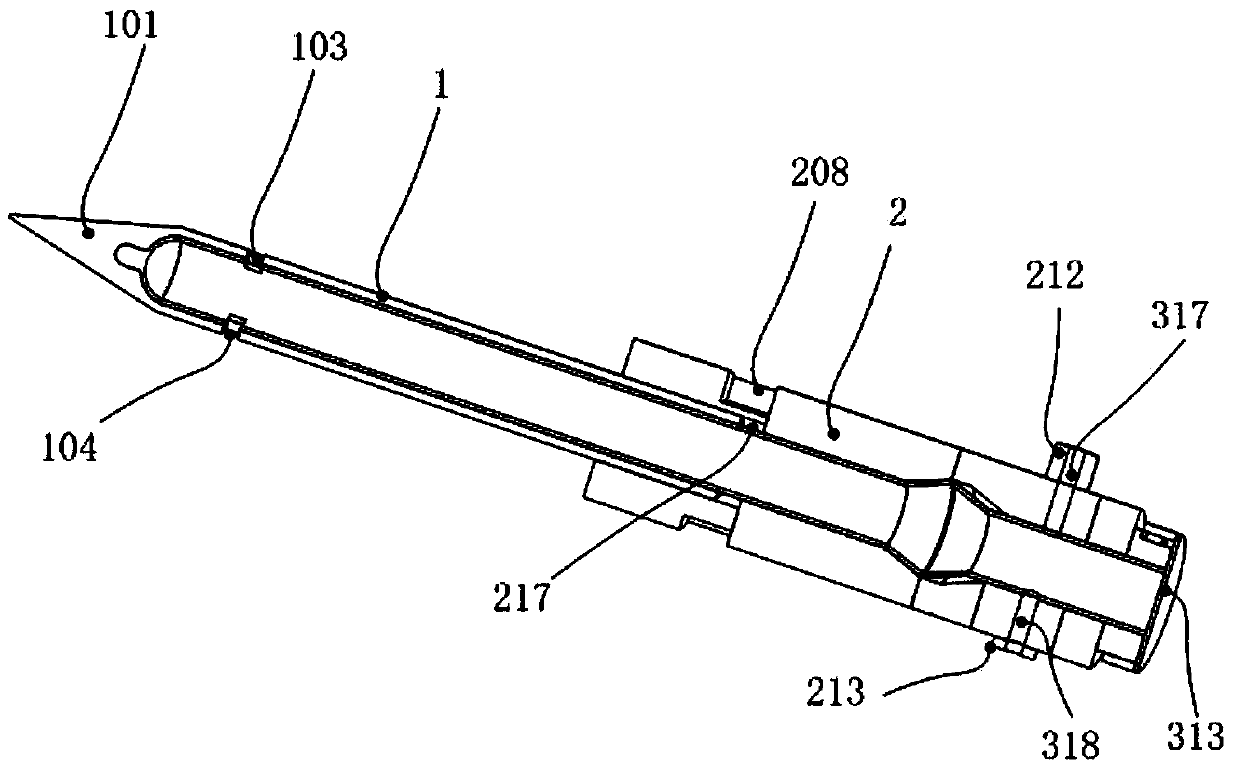

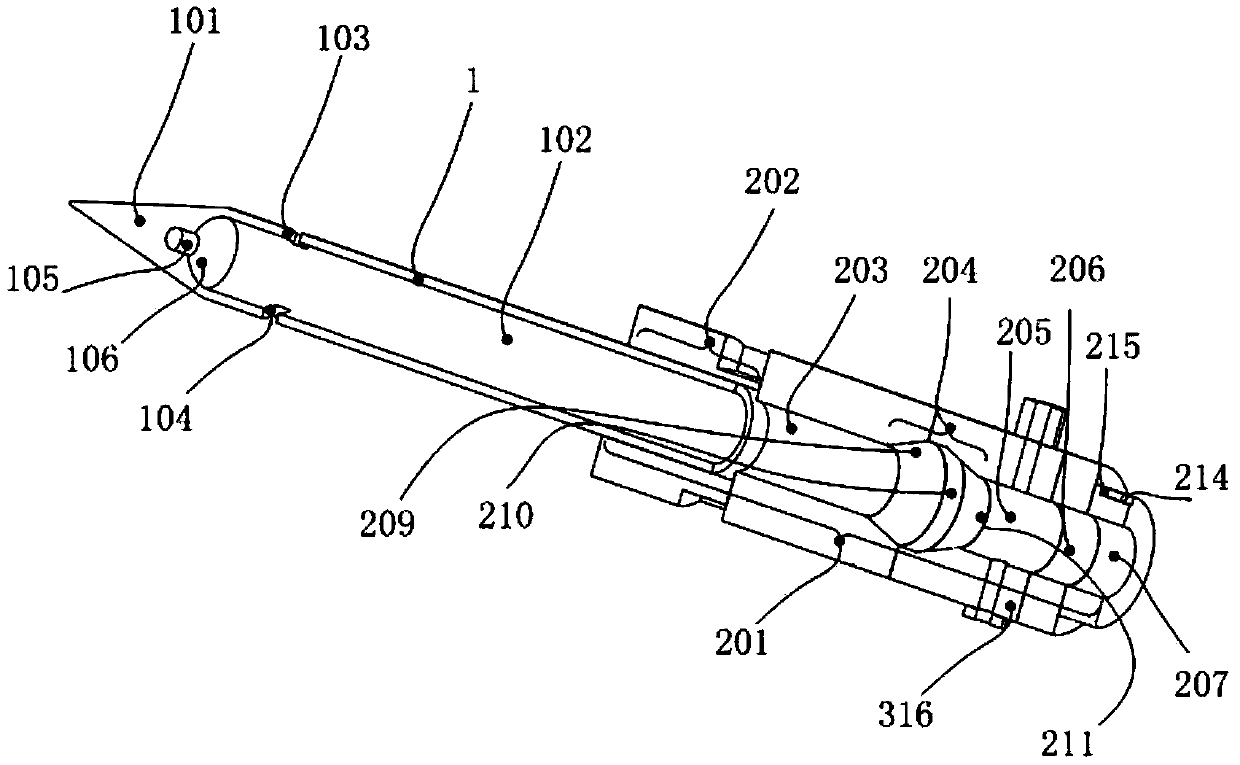

[0038] A sleeve-type lumbar puncture needle, comprising a cylindrical needle 1 with an inner cavity, a handle 2 with a through-tube cavity 201, and a trocar 3. One end of the needle 1 has a sharp head 101, and the other end Opening, the opening communicates with the hollow sleeve 102 provided inside the needle head 1, the needle head 1 is provided with a first liquid outlet hole 103 and a second liquid outlet hole 104 at one end close to the head, wherein the first liquid outlet hole The liquid outlet hole 103 and the second liquid outlet hole 104 are symmetrically arranged on the same cross-section along the needle head 1 and have the same size. The central angles of the first liquid outlet hole 103 and the second liquid outlet hole 104 are both 30°, which 1. The width in the axial direction is 4 mm. The handle 2 is made of transparent plastic material. The through-pipe cavity 201 includes a connecting cavity 202, a transition cavity 203, a limiting cavity 204, a functional ca...

Embodiment 2

[0050] Except that the outer wall of the multifunctional ledge 212 can be connected with a liquid medicine injection device in addition to the pressure measuring device, and the medicine liquid injection device is connected with the multifunctional ledge 212 through a rubber sealing device, the rest is the same as that of the first embodiment.

[0051] Method of use When it is necessary to use a syringe to inject medicine, it is necessary to push the back seat 313 into the liquid stop groove 214 in advance, insert the nipple at the front end of the syringe cylinder into the multifunctional protrusion 212, seal it with a rubber sealing strip, and then pull out the back seat 313 to use it. It enters the liquid discharge tank 215, rotates the rear seat 213, and opens between the third liquid inlet 314 and the first liquid outlet 103 or between the first liquid inlet 303 and the second liquid inlet 304 and the first liquid outlet respectively as required. The channel between the ho...

Embodiment 3

[0053] The rest is the same as that of Embodiment 2 except that the liquid-taking platform 213 is provided with a liquid-taking device.

[0054] The method of use is as follows:

[0055] Step 1: Ask the patient to lie on his side on a hard board bed, with his back perpendicular to the bed surface, his head forward, his chest bent, and his hands hugging his knees close to his abdomen so that his trunk is arched for easy needle insertion;

[0056] Step 2: Determine the puncture point, usually in the spinous process space of the 3rd to 4th lumbar vertebrae, sometimes in the previous or next lumbar vertebral space;

[0057] Step 3: After routine disinfection of the skin, wear sterile gloves and a hole patch, and use 2% lidocaine for local anesthesia from the skin to the intervertebral ligament;

[0058] Step 4: Before use, insert the sliding card 319 of the present invention into the stopper groove 214, hold the lumbar puncture needle of the present invention, and insert the need...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com