Incineration fly ash bi-component heavy metal stabilizer and fly ash treatment method applying same

A heavy metal stabilizer and fly ash incineration technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high price, environmental pollution, high processing cost, etc., to improve stabilization efficiency and reduce The cost of use, the effect of good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

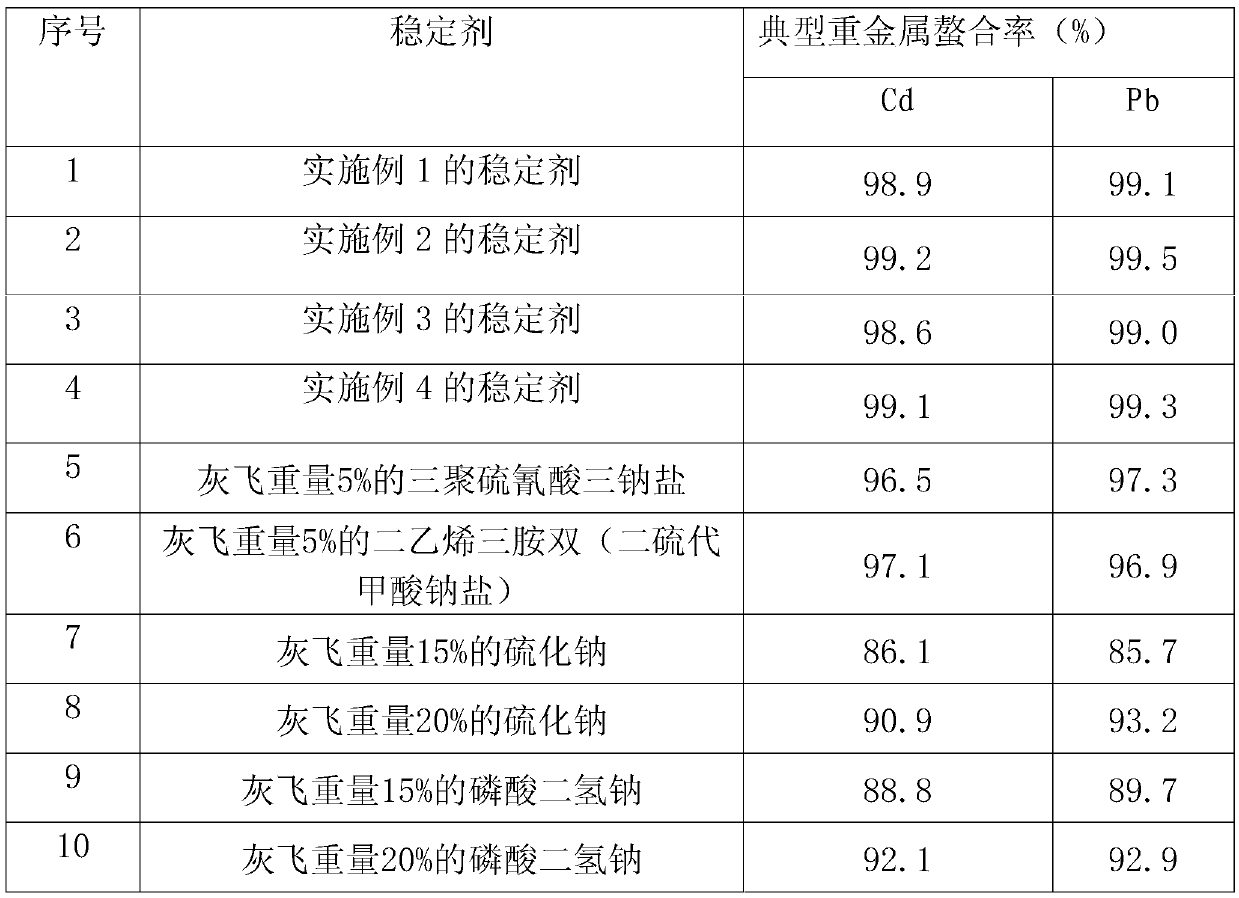

Examples

Embodiment 1

[0027] In the incineration fly ash two-component heavy metal stabilizer of the present embodiment, the A component includes 0.1 part of activator, and the B component is 2 parts of phosphate, 3 parts of organic sulfur and 1 part of inorganic sulfur; adopt this stabilizer to incinerate fly ash Heavy metal stabilization treatment, including the following steps:

[0028] Mix the fly ash with the aqueous solution of component A to activate the reaction for 20 minutes, then add the aqueous solution of component B, mix and stir for 0.5 hours, and finally cure at room temperature for 24 hours. The concentration of the aqueous solution of component A is 10% , And the amount of component A is 0.01% of the weight of fly ash; the concentration of the aqueous solution of component B is 30%, and the amount of component B is 2.1% of the weight of fly ash.

[0029] In this embodiment, the activator is sodium dodecylbenzenesulfonate. In this embodiment, sodium dodecylbenzenesulfonate is repla...

Embodiment 2

[0034] In the incineration fly ash two-component heavy metal stabilizer of the present embodiment, the A component includes 0.1 part of activator, and the B component is 2 parts of phosphate, 2 parts of organic sulfur and 3 parts of inorganic sulfur; Gray heavy metal stabilization treatment, including the following steps:

[0035] Mix the fly ash and the aqueous solution of component A to activate the reaction for 20 minutes, then add the aqueous solution of component B, mix and stir for 0.5 hours, and finally cure at room temperature for 24 hours; the concentration of the aqueous solution of component A is 30% and the concentration of component A The dosage is 1% of the weight of the fly ash; the concentration of the aqueous solution of the B component is 50% and the dosage of the B component is 25% of the weight of the fly ash.

[0036] In this embodiment, the activator is sodium dodecylbenzenesulfonate. In this embodiment, sodium dodecylbenzenesulfonate is replaced by hexad...

Embodiment 3

[0041] The incineration fly ash two-component heavy metal stabilizer of the present embodiment, A component comprises 0.01 part of activator, B component comprises 1 part of phosphate, 0.1 part of organic sulfur and 1 part of inorganic sulfur; Adopt this stabilizer to incinerate fly ash Heavy metal stabilization treatment, including the following steps:

[0042] Mix the fly ash with the aqueous solution of component A to activate the reaction for 0.1 hour, then add the aqueous solution of component B, mix and stir for 0.1 hour, and finally cure at room temperature for 48 hours; the aqueous solution concentration of component A is 20% and component A The dosage is 0.05% of the weight of the fly ash; the concentration of the aqueous solution of the B component is 40% and the dosage of the B component is 10% of the weight of the fly ash.

[0043] In this embodiment, the activator is cetyltrimethylammonium chloride. In this embodiment, cetyltrimethylammonium chloride is replaced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com