Method for preparing double-metal composite material by solid-liquid combination of solid-state copper material and drawing composition

A composite material and solid-liquid compounding technology, which is applied in the preparation of bimetallic composite materials by solid-liquid composite casting and drawing combination of copper materials, and in the field of bimetallic composite materials prepared by solid-liquid composite casting and drawing combination process, which can solve thermal cracking , low performance of interactive bimetal composite materials, composition segregation and other problems, to avoid oxidation slag, improve mechanical properties and physical properties, and improve shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

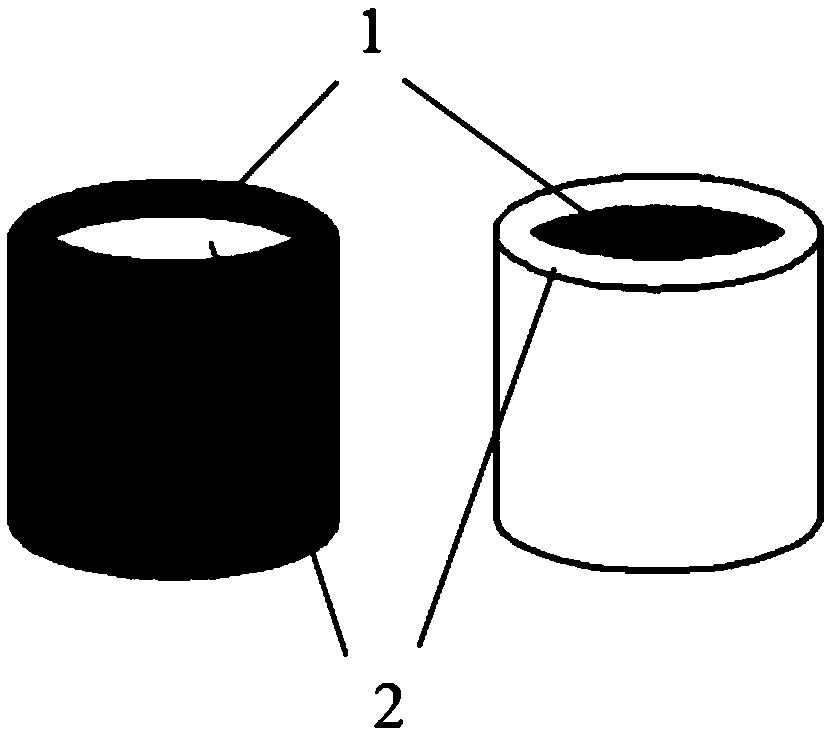

Image

Examples

Embodiment 1

[0031] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid composite and drawing combination of solid copper materials, including the following steps:

[0032] Step 1. Perform thermal spraying zinc surface treatment on the solid Cu-Cr-Zr copper alloy preset material to be connected, and the thickness of the zinc layer is 15 μm;

[0033] Step 2: Pre-position the solid Cu-Cr-Zr copper alloy after surface treatment at the desired position in the mold cavity;

[0034] Step 3: Melting the 6101 extruded aluminum alloy in a resistance furnace and pouring it into the mold cavity, using the metal mold casting process, the pouring temperature is 680°C, so that a metallurgical bond between copper and aluminum is formed;

[0035] Step 4. The obtained Cu-Cr-Zr-6101 copper-aluminum bimetallic drawing blank is annealed before drawing, the annealing temperature is 100°C, the annealing time is 300min, and then the drawing process is continued, and the proce...

Embodiment 2

[0039] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid composite and drawing combination of solid copper materials, including the following steps:

[0040] Step 1. Perform thermal spraying zinc surface treatment on the solid T2 red copper preset material to be connected, and the thickness of the zinc layer is 15 μm;

[0041] Step 2: Preset the solid T2 copper after surface treatment at the desired position in the mold cavity;

[0042] Step 3: Melt the A356 cast aluminum alloy in the resistance furnace and pour it into the mold cavity. Using the squeeze casting process, the pouring temperature is 700°C, and the squeeze casting pressure is 70MPa to form a metallurgical bond between copper and aluminum;

[0043] Step 4. The obtained T2-A356 copper-aluminum bimetallic drawing blank is annealed before drawing, the annealing temperature is 300℃, the annealing time is 50min, and then the drawing process is continued. The process is continuous ...

Embodiment 3

[0047] This embodiment relates to a method for preparing a bimetallic composite material by solid-liquid composite and drawing combination of solid copper materials, including the following steps:

[0048] Step 1. Perform thermal spraying zinc surface treatment on the solid T2 red copper preset material to be connected, and the thickness of the zinc layer is 15 μm;

[0049] Step 2: Preset the solid T2 copper after surface treatment at the desired position in the mold cavity;

[0050] Step 3: Melting the AZ91 magnesium alloy in the resistance furnace and pouring it into the mold cavity, using the squeeze casting process, the pouring temperature is 650℃, and the squeeze casting pressure is 50MPa, so that a metallurgical bond between aluminum and magnesium is formed;

[0051] Step 4. The obtained T2-AZ91 copper-magnesium bimetal is subjected to drawing processing, the process is straight drawing, the drawing temperature is 250°C, the reduction ratio is 40 / 100, and the drawing speed is 20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com