A kind of guar gum-chitosan natural flocculant and preparation method thereof

A flocculant and guar gum technology, applied in the field of natural polymers, can solve the problem of less natural flocculants, etc., and achieve the effect of simple preparation method, good safety, and reduced COD efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of guar gum-chitosan natural thing flocculant, concrete steps are as follows:

[0041] (1) Preparation of guar gum emulsion

[0042] At room temperature, dissolve 2 parts of guar gum powder and 1 part of surfactant in 800 parts of water, stir and let stand for 4 hours;

[0043] (2) Chitosan emulsion preparation

[0044] Dissolve 1 part of chitosan powder in 80 parts of acetic acid solution, stir and let stand;

[0045] (3) Preparation of polyelectrolyte gel

[0046] Slowly add the solution obtained in step (2) to the solution in step (1), stir while adding, mix slowly, react at 15-40°C for 4 hours, and slowly add dropwise into the solidification liquid;

[0047] (4) Separation of products

[0048] Slowly add 6 parts of alcohol solvent to the mixed system to precipitate the product, filter it with suction, wash it and dry it.

Embodiment 2

[0050] A kind of preparation method of guar gum-chitosan natural thing flocculant, concrete steps are as follows:

[0051] (1) Preparation of guar gum emulsion

[0052] At room temperature, dissolve 5 parts of guar gum powder and 1 part of surfactant in 1000 parts of water, stir and let stand for 6 hours;

[0053] (2) Chitosan emulsion preparation

[0054]Dissolve 3 parts of chitosan powder in 100 parts of acetic acid solution, stir and let stand;

[0055] (3) Preparation of polyelectrolyte gel

[0056] Slowly add the solution obtained in step (2) to the solution in step (1), stir while adding, mix slowly, continue to react for 6 hours after mixing, and slowly add dropwise to the solidified liquid;

[0057] (4) Separation of products

[0058] Slowly add 8 parts of alcohol solvent to the mixed system to precipitate the product, filter it with suction, wash it and dry it.

Embodiment 3

[0060] A kind of preparation method of guar gum-chitosan natural flocculant, concrete steps are as follows:

[0061] (1) Preparation of guar gum emulsion

[0062] At room temperature, dissolve 10 parts of guar gum powder and 2 parts of surfactant in 1000 parts of water, stir and let stand for 8 hours;

[0063] (2) Chitosan emulsion preparation

[0064] Dissolve 5 parts of chitosan powder in 100 parts of acetic acid solution, leave standstill after stirring;

[0065] (3) Preparation of polyelectrolyte gel

[0066] Slowly add the solution obtained in step (2) to the solution in step (1), stir while adding, mix slowly, and after reacting for 8 hours, slowly add it dropwise into the solidified liquid;

[0067] (4) Separation of products

[0068] Slowly add 10 parts of alcoholic solvent to the mixed system to precipitate the product, filter it with suction, wash it and dry it.

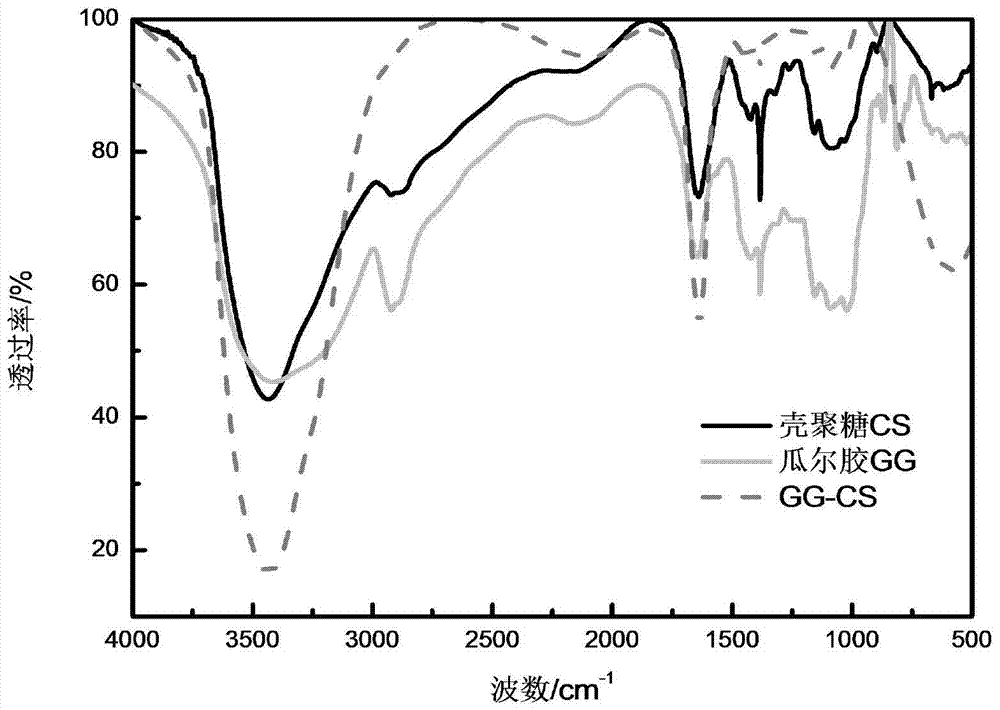

[0069] The carboxymethyl hydroxyethyl guar gum that embodiment 1-3 prepares is analyzed with Fourie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com