Sulfurgypsum for ceramic mold and preparation method of sulfurgypsum

A ceramic mold and sulfur gypsum technology, which is applied in the field of sulfur gypsum, can solve the problems of high content of impurities in sulfur gypsum waste, and achieve the effect of being suitable for large-scale production, conducive to shaping, and compact in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

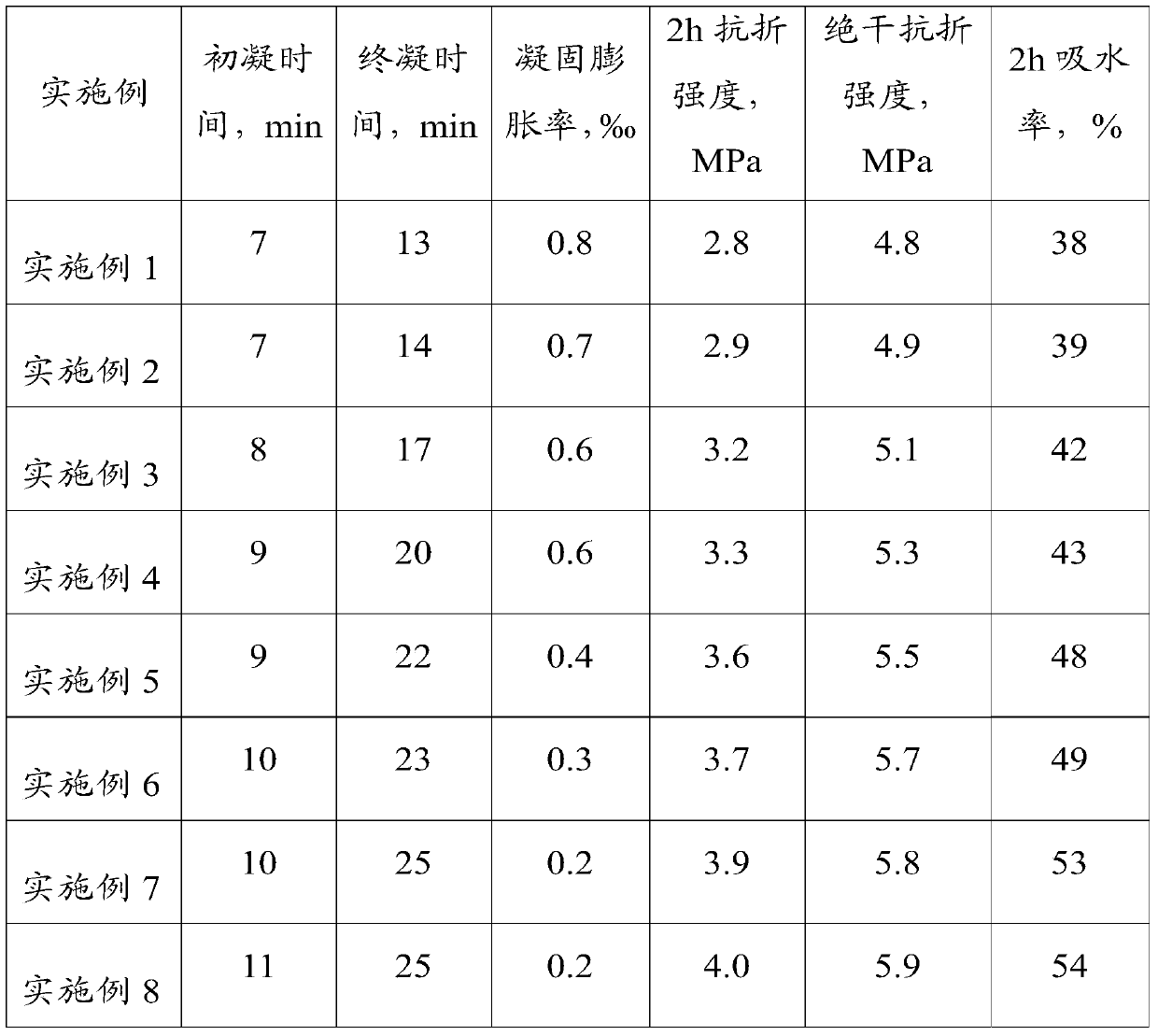

Examples

Embodiment 1

[0056] A preparation method of sulfur gypsum for ceramic mould, comprising the steps:

[0057] (1) Flash burning: in a nitrogen atmosphere, the flue gas temperature is heated to 800°C within 1h, and the sulphur gypsum is calcined at this temperature for 1h;

[0058] (2) desulfurization process: adopt the semi-dry FGD technology of desulfurization in a dry state and regenerate the desulfurizer in a wet state to desulfurize the sulfur gypsum obtained in step (1); the desulfurizer used is activated carbon;

[0059] (3) Adding auxiliary materials: adding citric acid accounting for 0.1% of the mass of the sulfur gypsum to the sulfur gypsum obtained in step (2), stirring and mixing evenly, to obtain a sulfur gypsum for ceramic molds.

Embodiment 2

[0061] A preparation method of sulfur gypsum for ceramic mould, comprising the steps:

[0062] (1) Flash burning: in a nitrogen atmosphere, the flue gas temperature is heated to 900 °C within 1 h, and the sulfur gypsum is calcined at this temperature for 5 h;

[0063] (2) desulfurization process: adopt the semi-dry FGD technology of desulfurization in dry state and regenerate desulfurizer in wet state to desulfurize the sulfur gypsum obtained in step (1); the desulfurizer used is ZSM-5 molecular sieve;

[0064] (3) Adding auxiliary materials: adding tartaric acid, which accounts for 2% of the mass of the sulfur gypsum, to the sulfur gypsum obtained in the step (2), stirring and mixing evenly, to obtain a sulfur gypsum used for a ceramic mold.

Embodiment 3

[0066] A preparation method of sulfur gypsum for ceramic mould, comprising the steps:

[0067] (1) Flash burning: in a nitrogen atmosphere, the flue gas temperature is 860 °C at a heating rate of 20 °C / min, and the sulfur gypsum is calcined at this temperature for 3 hours;

[0068] (2) desulfurization process: adopt water washing mode to carry out desulfurization treatment to the obtained sulphur gypsum in step (1), and the amount of water added is 1 times of the quality of sulphur gypsum; the adopted desulfurizing agent is calcium hydroxide;

[0069] (3) Adding auxiliary materials: adding sodium tartrate accounting for 0.5% of the mass of the thiogypsum to the thiogypsum obtained in step (2), stirring and mixing evenly, to obtain a thiogypsum for ceramic molds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com