A kind of degradable environmental protection coating and preparation method thereof

An environmentally friendly coating and environmental protection technology, applied in the direction of lignin coating, starch derivative coating, coating, etc., can solve the problems such as not easy to clean, and achieve the effect of improving the open time and viscous strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the degradable environmental protection coating described in any of the above embodiments, comprising the following steps:

[0038] 1: Weigh the corresponding water according to the formula and pour it into the reaction kettle, turn on the mixer, adjust the speed to 800r / min, add some low-odor environmental protection additives in turn, and stir for 5 minutes;

[0039] 2: Add titanium dioxide, oxidatively modified tapioca starch, and inorganic filler in turn, adjust the speed to 1200r / min, and stir for 40min;

[0040] 3: Adjust the rotation speed to 800r / min, add natural polar negative ion minerals, stir for 5 minutes, add beating denatured wood pulp solution, oil-resistant plasticizer in turn, and stir for 8 minutes;

[0041] 4: Add another part of low-odor environmental protection additives in sequence, and stir for 20 minutes to prepare the degradable environmental protection coating.

[0042] The above-men...

Embodiment 1

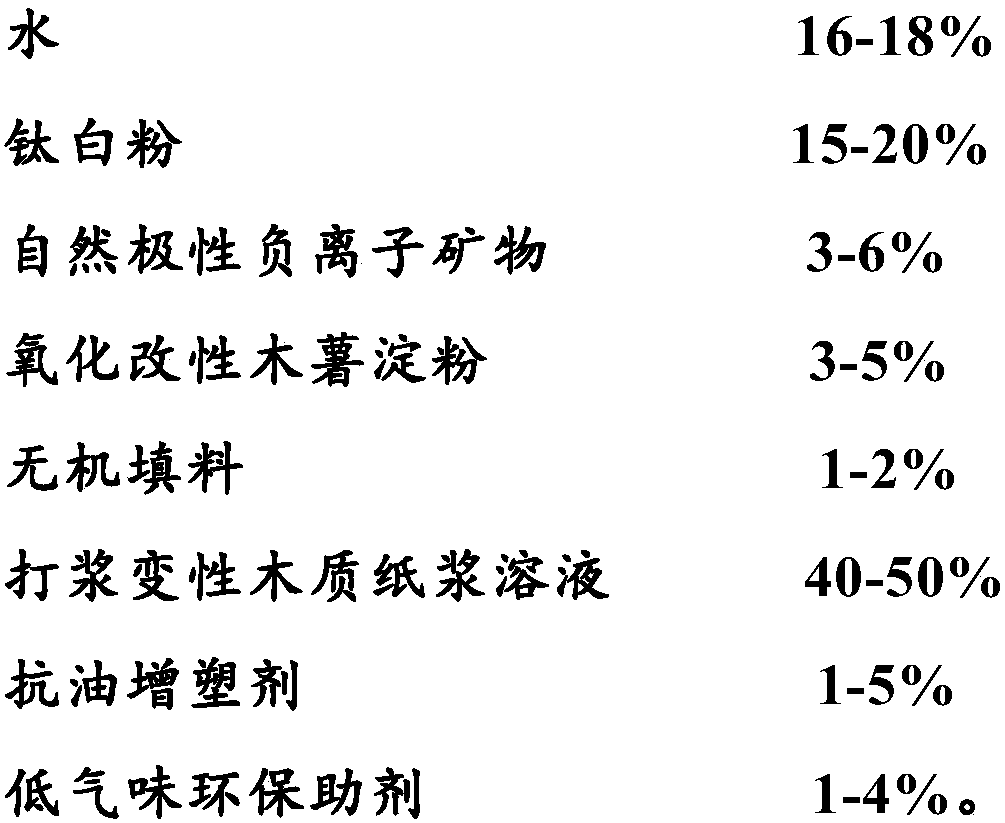

[0045] The mass percentage of the component and component of an embodiment of degradable environmental protection coating of the present invention is:

[0046]

[0047] The degradable environmental protection coating is prepared by the following steps:

[0048] 1: Weigh the corresponding water according to the formula and pour it into the reaction kettle, turn on the mixer, adjust the speed to 800r / min, add some low-odor environmental protection additives in turn, and stir for 5 minutes;

[0049] 2: Add titanium dioxide, oxidatively modified tapioca starch, and inorganic filler in turn, adjust the speed to 1200r / min, and stir for 40min;

[0050]3: Adjust the rotation speed to 800r / min, add natural polar negative ion minerals, stir for 5 minutes, add beating denatured wood pulp solution, oil-resistant plasticizer in turn, and stir for 8 minutes;

[0051] 4: Add another part of low-odor environmental protection additives in sequence, and stir for 20 minutes to prepare the de...

Embodiment 2

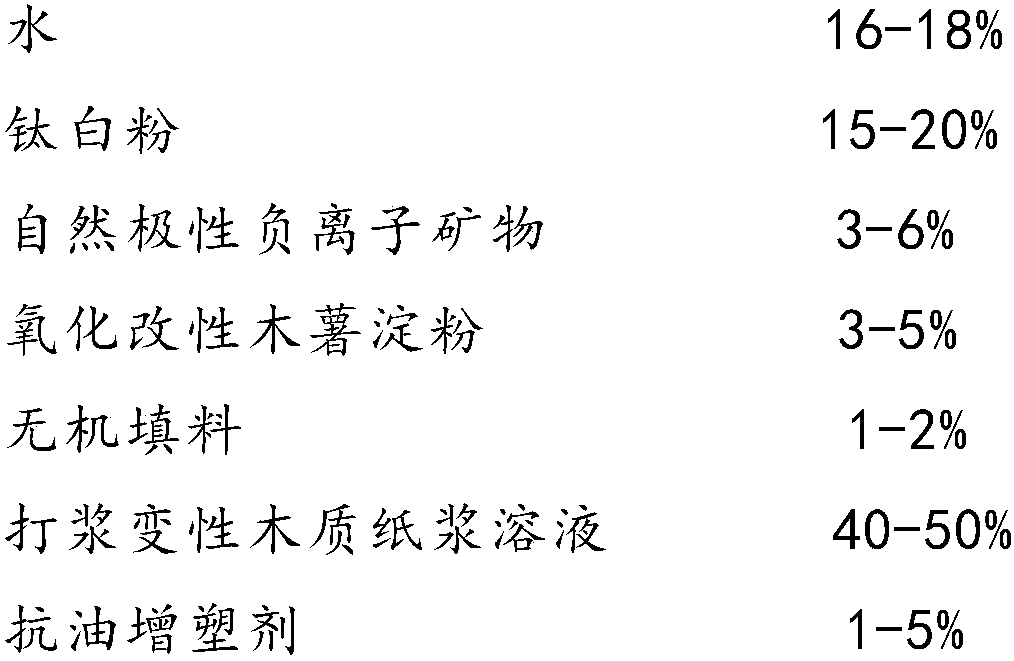

[0071] The mass percentage of the component and component of another embodiment of the degradable environmental protection coating of the present invention is:

[0072]

[0073] The preparation method of the degradable environmentally friendly coating is the same as that of Example 1, and will not be repeated. The degradable environmentally friendly coating has been tested, and the indicators are as follows:

[0074] 1. Contrast ratio: 0.94

[0075] 2. Scrub resistance: >1000 times

[0076] 3. Low temperature stability: no deterioration

[0077] 4. Alkali resistance: no abnormality within 24 hours

[0078] 5. The state in the container: uniform without lumps

[0079] 6. Appearance of coating film: normal

[0080] 7. Constructability: two coats without barriers

[0081] 8. Volatile organic compounds (VOC): not detected

[0082] 9. Total of glycol ethers and their esters (ethylene glycol methyl ether, ethylene glycol methyl ether acetate, ethylene glycol ethyl ether, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com