Heavy oil catalytic cracking method and device

A technology of catalytic cracking and heavy oil catalysis, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of catalytic cracking technology, such as low yield and no advantage, to improve the total conversion rate, facilitate operation, and increase yield And the effect of liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

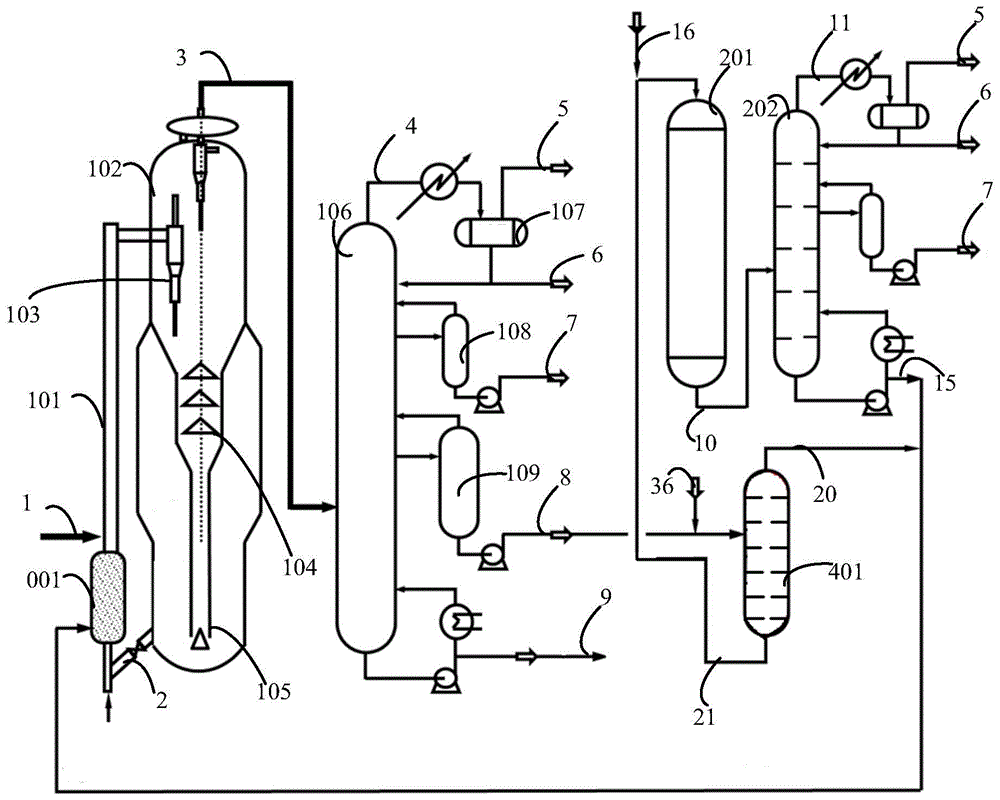

[0058] The heavy oil catalytic cracking method provided in this example uses such as figure 1 device shown. The device includes at least:

[0059] Riser 101, the bottom of the riser 101 is provided with a heavy oil inlet and a riser inlet, and the top is provided with a riser outlet; a fast bed 001, the top of the fast bed 001 is provided with a fast bed outlet, and the bottom is provided with a catalyst inlet and a catalytic hydrogenation heavy oil inlet Oil and gas separation system, the oil and gas separation system includes a settler 102, the stripping section 104 that is arranged below the settler 102 and communicates with it, and the regenerator 105 that communicates with the stripping section 104, and the settler 102 is provided with oil and gas and catalyst mixture material inlet, the top of the oil-gas separation system is also provided with an oil-gas outlet, and the regenerator 105 is provided with a catalyst outlet;

[0060] A main fractionation tower 106, the ma...

Embodiment 2

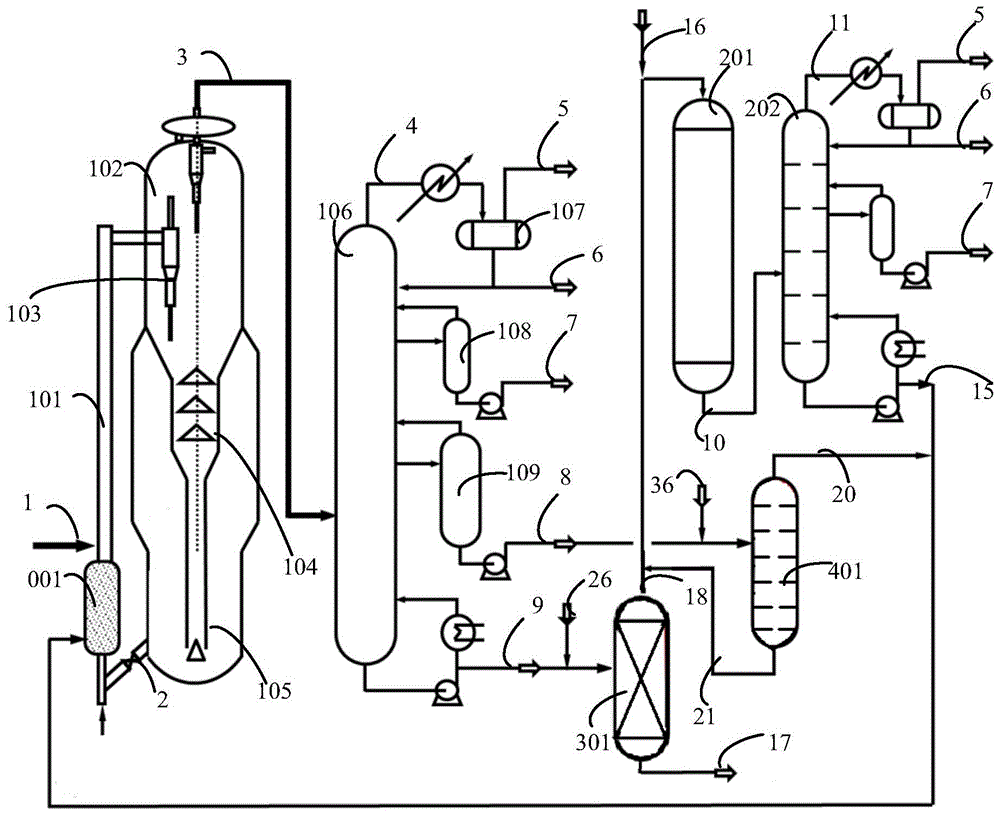

[0085] The heavy oil catalytic cracking method provided in this example uses such as figure 2 device shown. Different from the catalytic cracking device in Example 1, the device of this embodiment also includes: an extraction tower 301, the extraction tower 301 has an extraction tower inlet, a deoiled bitumen outlet and a deasphalted oil outlet, and the extraction tower inlet The oil slurry outlet of the main fractionation tower 106 is connected, and the deasphalted oil outlet is connected with the inlet of the catalytic hydroprocessing unit 201 .

[0086] The difference between the method for heavy oil catalytic cracking using the device provided in this example and the method in Example 1 is that after the oil slurry 9 is drawn from the bottom of the main fractionation tower 106, it is used for the extraction of asphaltenes in the oil slurry. After the solvent 26 is mixed, it enters the extraction tower 301 for deasphalting treatment. The extraction solvent 26 is selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com