Coal water slurry gasification process method suitable for treating waste water containing high-concentration ammonia and nitrogen and COD

A process method, coal water slurry technology, applied in chemical instruments and methods, combustible gas purification, water/sewage treatment, etc., to achieve the effects of low power consumption, cheap and suitable materials for equipment selection, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

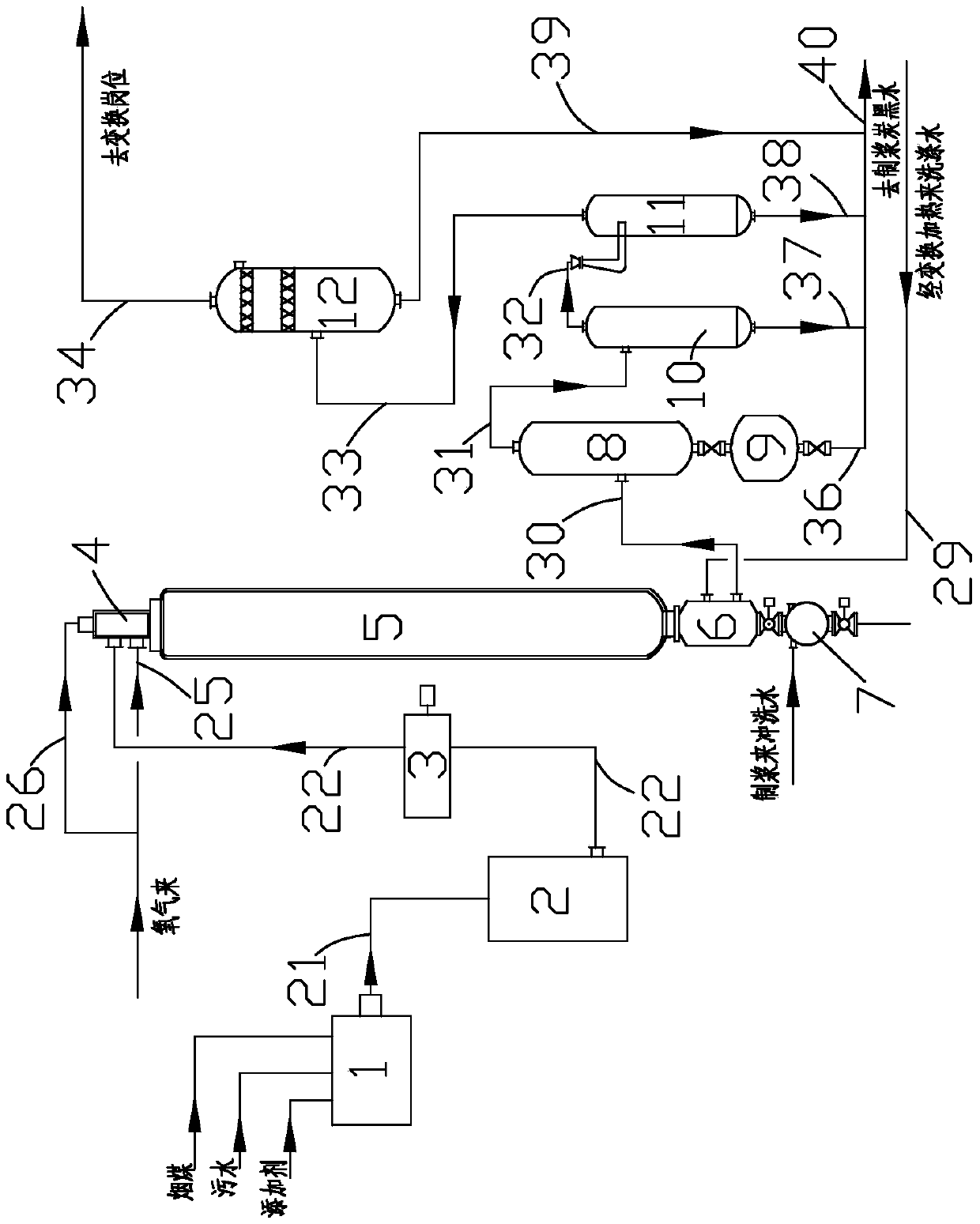

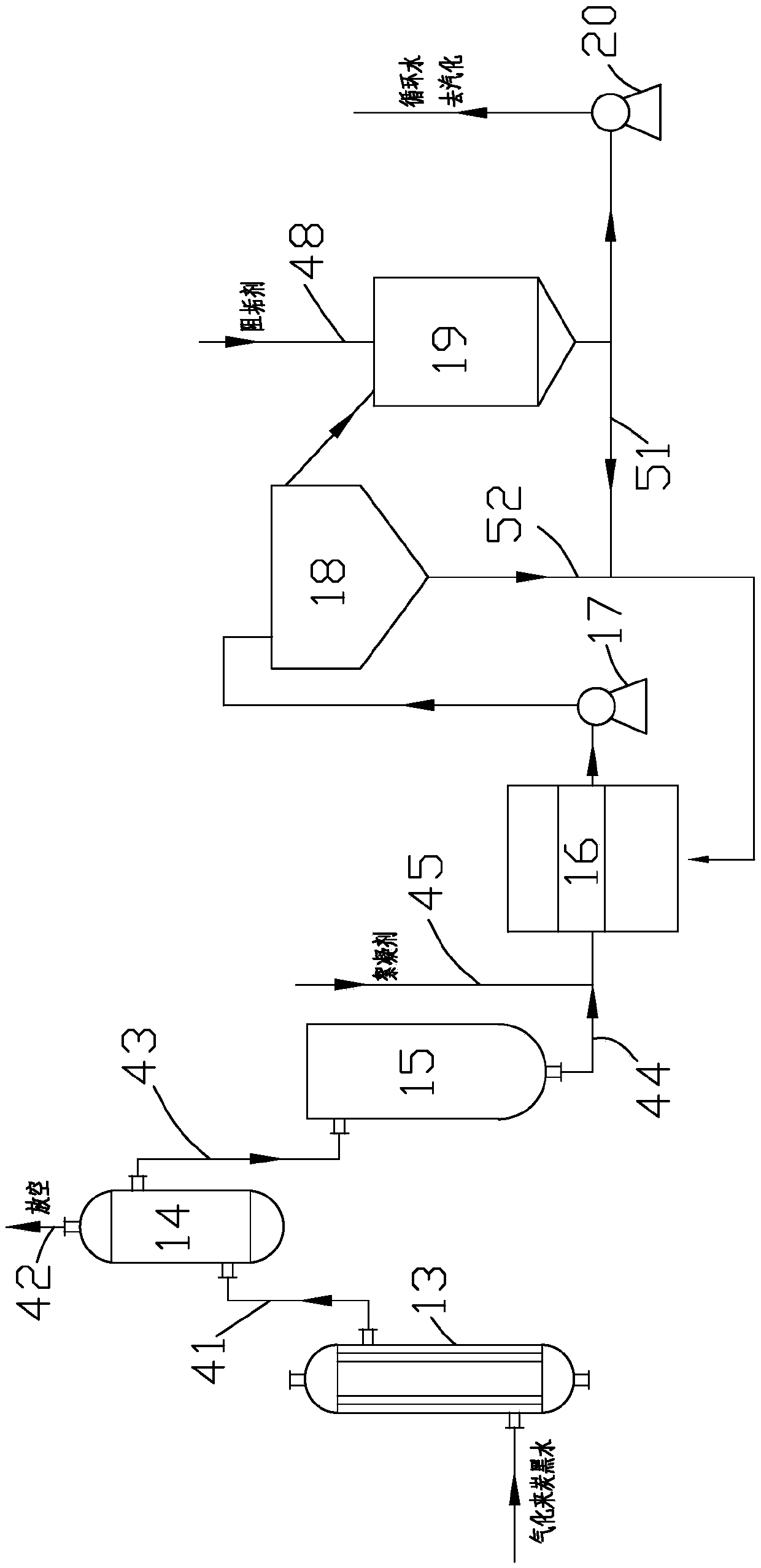

[0039] Such as Figure 1 to Figure 2 Shown, be that the present invention is a kind of coal-water slurry gasification process that is applicable to processing high-concentration ammonia nitrogen, COD sewage, comprises the steps:

[0040] 1) Preparation of coal water slurry

[0041] Grind bituminous coal, high-concentration ammonia nitrogen, COD sewage and additive mixture in ball mill 1 to prepare coal-water slurry, then send the slurry to slurry tank 2 through the first pipeline 21, and then pump the coal-water slurry through the slurry pump 3 The slurry is sent to the gasifier;

[0042] The problem of instability of coal-water slurry containing high-concentration sewage is solved by choosing the proportion of bituminous coal from different mines and the selective quantitative proportion of additives for sewage with different concentrations.

[0043] 2) Combustion in coal water slurry gasifier

[0044] The coal-water slurry enters the nozzle 4 through the second pipeline 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com