Nodular cast iron winding drum high in strength and ductility and preparation method thereof

A ductile iron, high-strength technology, applied in the field of ductile iron materials, can solve the problems of low ductility of castings, achieve the effects of low raw material and production costs, improve strength, and delay spheroidization recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of above-mentioned nodular cast iron reel, comprises the following steps:

[0042] 1) Smelting: heating and melting the mixed material of pig iron, scrap steel, recycled material, ferrosilicon, ferromolybdenum and metallic nickel into molten iron;

[0043] When the temperature of the molten iron reaches 1490°C-1520°C, the composition of the molten iron is adjusted in front of the furnace so that the molten iron includes the following components by weight percentage: 3.0%-3.3% C; 3.8%-4.2% Si; Mn<0.3%; S<0.02 %; P<0.03%; 0.2%-0.3% Mo; 0.12%-0.15% Ni; the balance is Fe and unavoidable impurities;

[0044] When the composition of molten iron is qualified, remove the slag;

[0045] Then, keep warm for 3 minutes to 5 minutes, and then prepare the molten iron to come out of the furnace.

[0046] 2) Spheroidization treatment: place the low-rare-earth magnesium alloy nodulizer on the bottom of the ladle, cover i...

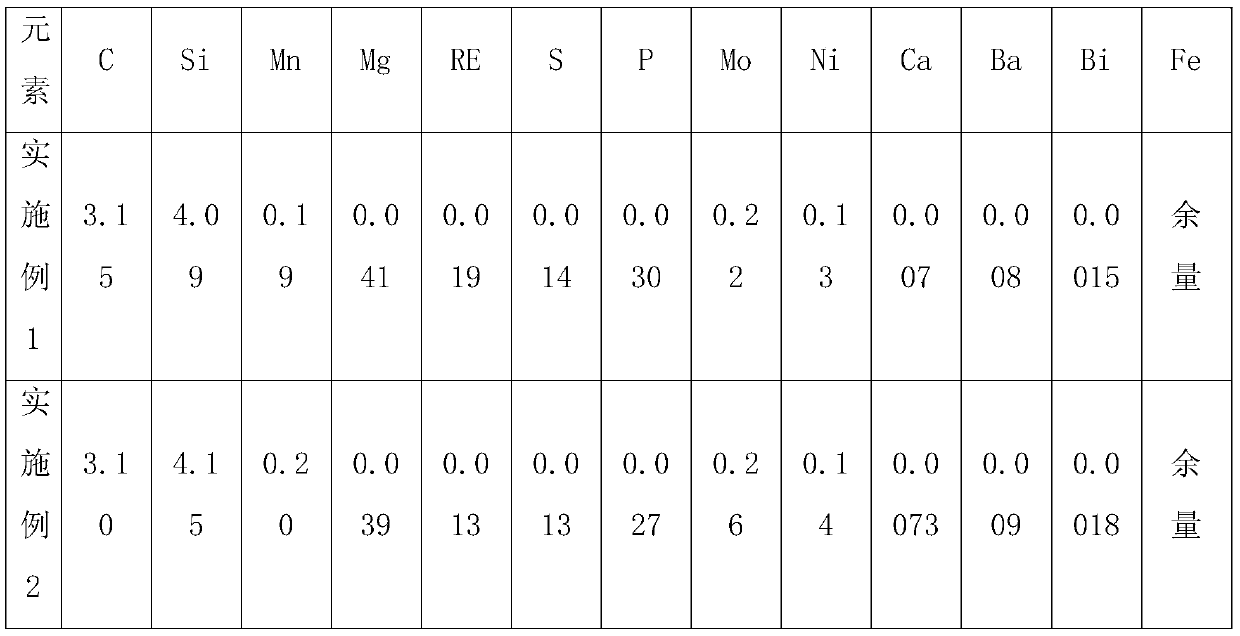

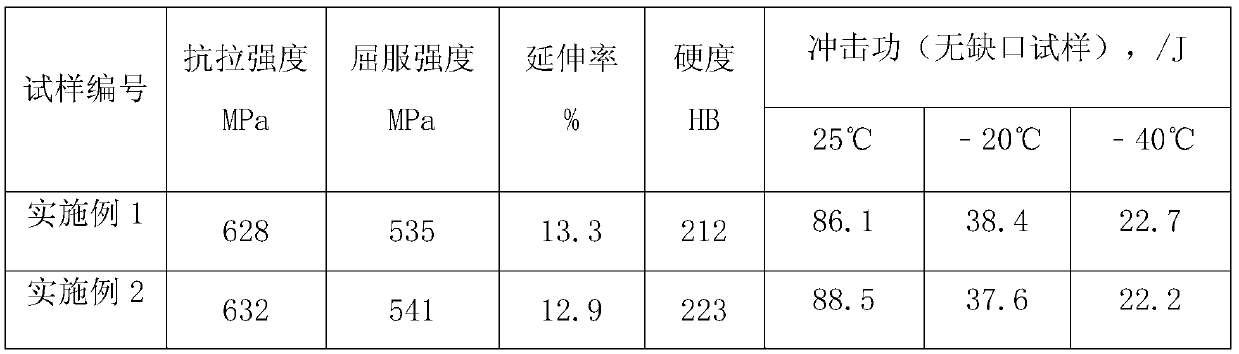

Embodiment 1

[0057] Using a 3-ton intermediate frequency electric furnace to smelt molten iron includes the following steps:

[0058] 1) Smelting: heating and melting the mixed material of pig iron, scrap steel, recycled material, ferrosilicon, ferromolybdenum and metallic nickel into molten iron;

[0059] The weight percent of the added pig iron is 40%, the weight percent of steel scrap is 27.42%, the weight percent of returned charge is 30%, the weight percent of ferrosilicon is 2.0% and the weight percent of silicon in the described ferrosilicon is 75%, The weight percentage of molybdenum iron is 0.4%, and the weight percentage of molybdenum in said molybdenum iron is 60%, and the weight percentage of metal nickel is 0.18%, and its purity is 99.90%.

[0060] When the temperature of the molten iron reaches 1495°C, adjust the composition of the molten iron in front of the furnace so that the molten iron includes the following components in weight percentage: 3.0% C; 4.2% Si; Mn<0.3%; S<0....

Embodiment 2

[0074] Using a 3-ton intermediate frequency electric furnace to smelt molten iron includes the following steps:

[0075]1) Smelting: heating and melting the mixed material of pig iron, scrap steel, recycled material, ferrosilicon, ferromolybdenum and metallic nickel into molten iron;

[0076] The weight percent of the added pig iron is 40%, the weight percent of steel scrap is 25%, the weight percent of returned materials is 32.75%, the weight percent of ferrosilicon is 1.6% and the weight percent of silicon in the described ferrosilicon is 75%, The weight percentage of molybdenum iron is 0.5%, and the weight percentage of molybdenum in the said molybdenum iron is 60%, and the weight percentage of metallic nickel is 0.15%, and its purity is 99.90%.

[0077] When the temperature of the molten iron reaches 1505°C, adjust the composition of the molten iron in front of the furnace so that the molten iron includes the following components in weight percentage: 3.3% C; 3.8% Si; Mn<0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com