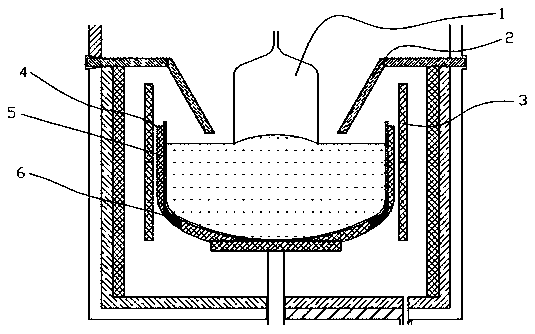

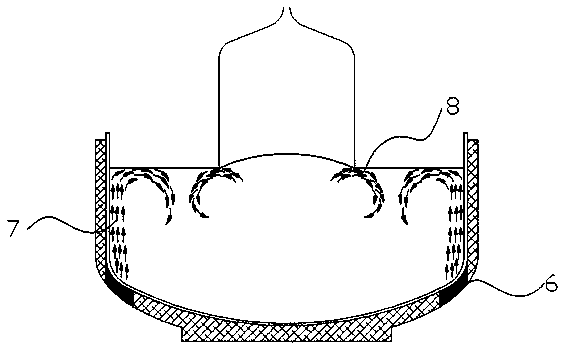

Monocrystalline silicon growth oxygen content control technology

A control technology, a technology of single crystal silicon, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of difficult to obtain high magnetic field strength, large power consumption, huge equipment investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Growth diameter of 2 inches of single crystal silicon. The outer diameter of the quartz crucible is 105 mm, the speed of the crucible is 8 rpm, the width of the oscillating wave input ring is 14 mm, and the weight is 5 kg. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the melt is scanned at a frequency of 1000-5000 Hz with a fixed amplitude, and no resonance frequency is found. Select the frequency of the oscillation wave to be 5000Hz, the amplitude to be 1.0μm, and the oscillation power P to be 0.25W / cm 2 , initial excitation force F 0 for 5t. Before the start of isometric growth after the crystal shoulder is turned, the oscillator wave input is turned on, and the crystal isodiametric growth starts at the same time. During the crystal growth process, according to equations (5) to (8), the excitation force F is continuously adjusted and reduced as the crystal grows, and the input of the oscillatory w...

Embodiment 2

[0039] Growth diameter of 2 inches of single crystal silicon. The outer diameter of the quartz crucible is 155 mm, the speed of the crucible is 6 rpm, the width of the oscillating wave input ring is 17 mm, and the weight is 8 kg. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the melt is scanned at a frequency of 1000-5000 Hz with a fixed amplitude, and no resonance frequency is found. Select the frequency of the oscillation wave to be 1360Hz, the amplitude to be 6.0μm, and the oscillation power P to be 0.67W / cm 2 , initial excitation force F 0 for 4t. Before the start of isometric growth after the crystal shoulder is turned, the oscillator wave input is turned on, and the crystal isodiametric growth starts at the same time. During the crystal growth process, according to equations (5) to (8), the excitation force F is continuously adjusted and reduced as the crystal grows, and the input of the oscillatory w...

Embodiment 3

[0042] Growth diameter of 4 inches of single crystal silicon. The outer diameter of the quartz crucible is 210 mm, the speed of the crucible is 8 rpm, the width of the oscillating wave input ring is 28 mm, and the weight is 11 kg. After the polysilicon is completely melted, stand still for 3h. When the surface of the silicon liquid is still, the melt is scanned at a frequency of 1000-5000 Hz with a fixed amplitude, and no resonance frequency is found. Select the oscillation wave frequency as 3260Hz, the amplitude as 2.0μm, and the oscillation power P as 0.43W / cm 2 , initial excitation force F 0 It is 9t. Before the start of isometric growth after the crystal shoulder is turned, the oscillator wave input is turned on, and the crystal isodiametric growth starts at the same time. During the crystal growth process, according to equations (5) to (8), the excitation force F is continuously adjusted and reduced as the crystal grows, and the input of the oscillatory wave is stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com