Cutting process simulation process for brittle materials

A simulation method and technology of brittle materials, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as mesh distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

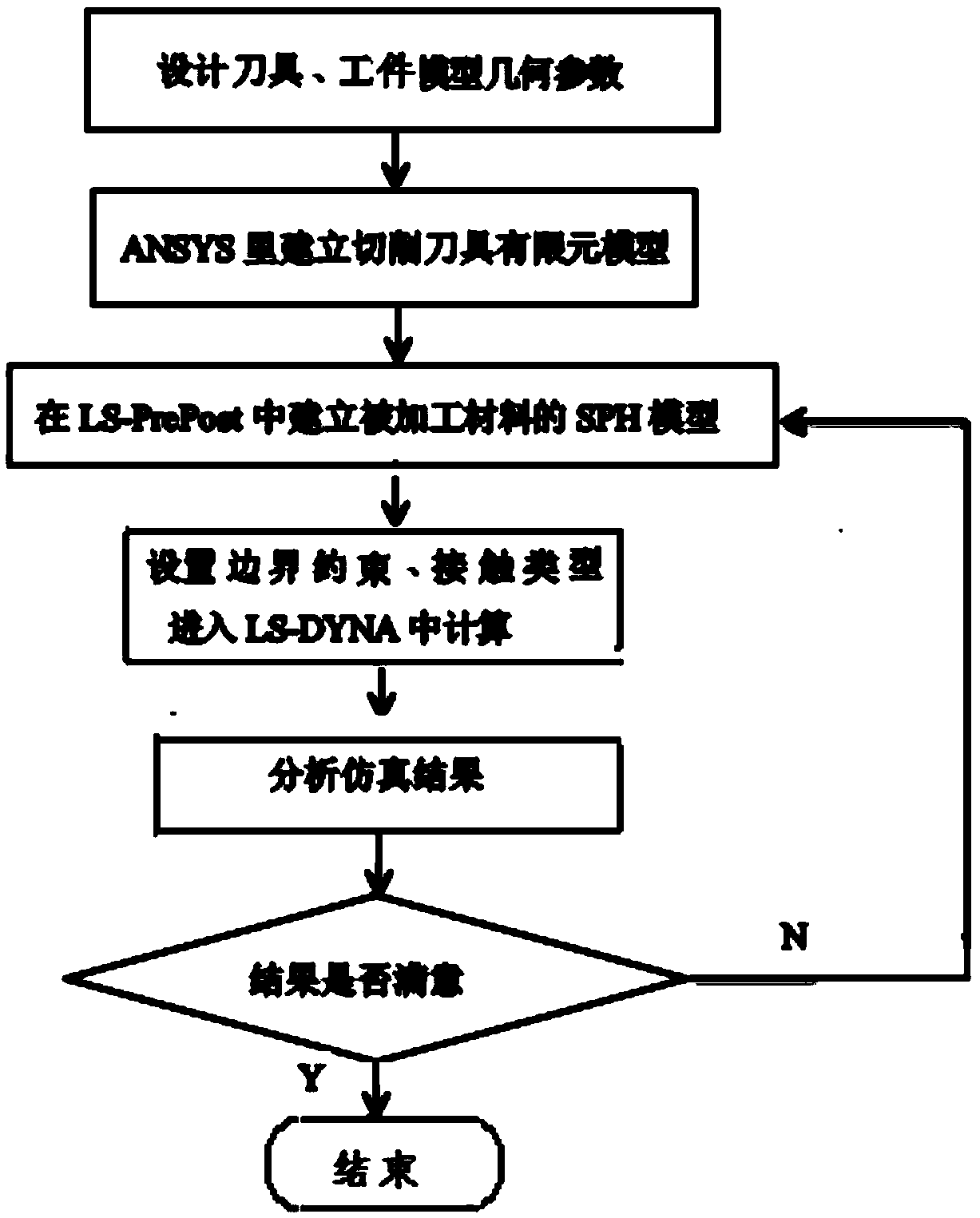

[0048] attached figure 1 It is a flow chart of the implementation process of the present invention. Taking quartz glass as an example, the simulation method of cutting process of brittle materials based on SPH algorithm is explained in detail. Specific steps are as follows:

[0049] Step 1: Set the dimensions of the tool and workpiece material. The tool material is diamond with a density of 3.51g / cm 3 , Elastic modulus 1141GPa, Poisson's ratio 0.07, tool rake angle 10°, relief angle 10°, cutting speed 10m / s. The quartz glass workpiece is designed to be 5×3×0.5μm 3 cube.

[0050] Step 2: Establish a 3D tool finite element model in ANSYS. Since the hardness of diamond is much higher than that of quartz glass, and the research focuses on the processing performance of quartz glass, the diamond tool is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com