Horizontal sublimation system

A horizontal, solid technology, applied in the direction of gas fuel, waste fuel, fuel, etc., can solve problems such as increasing fuel cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following description of illustrated embodiments, reference is made to the accompanying drawings which form a part hereof, and in which are shown by way of illustration various embodiments in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural and functional changes may be made without departing from the scope of the present invention.

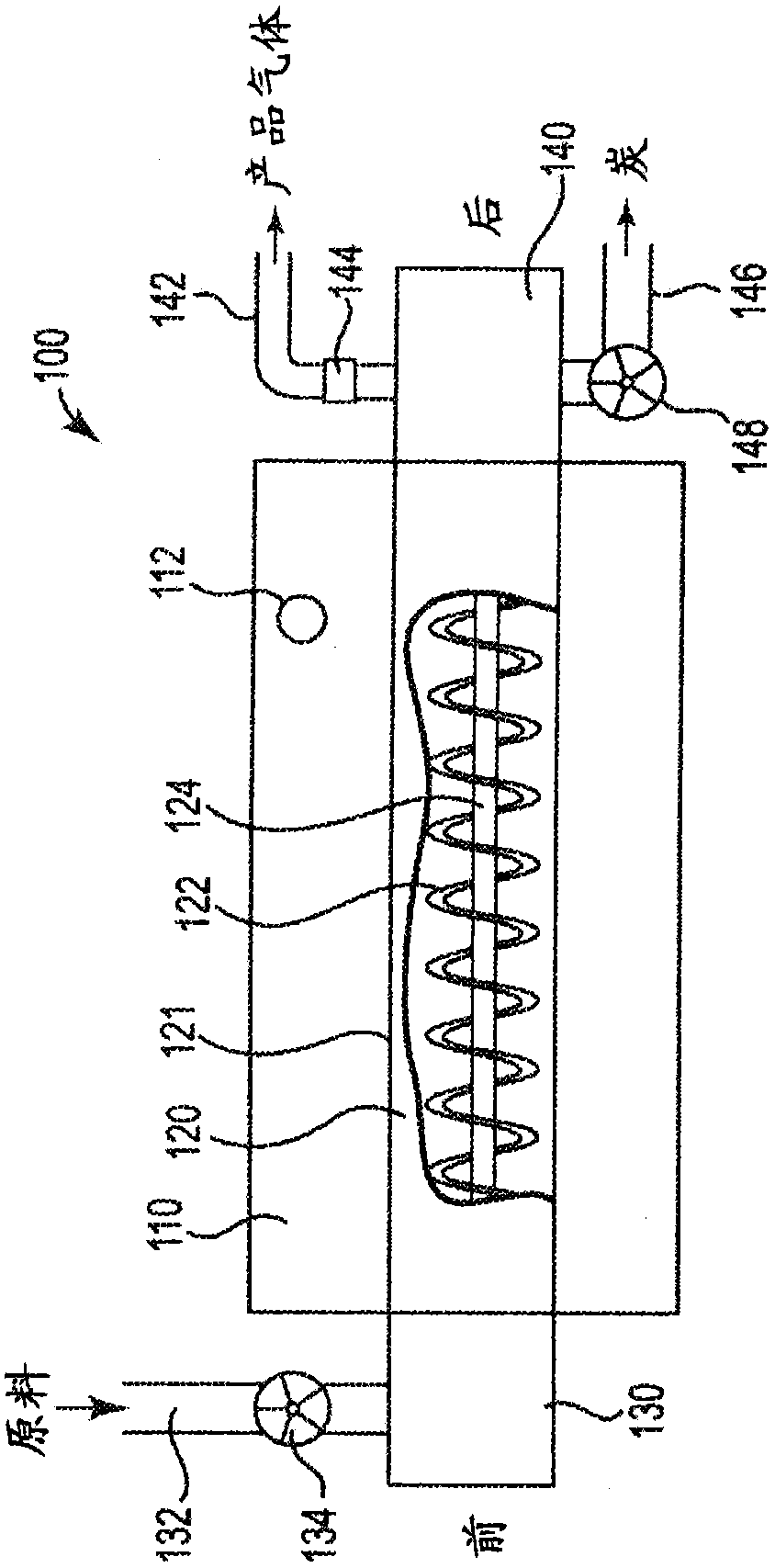

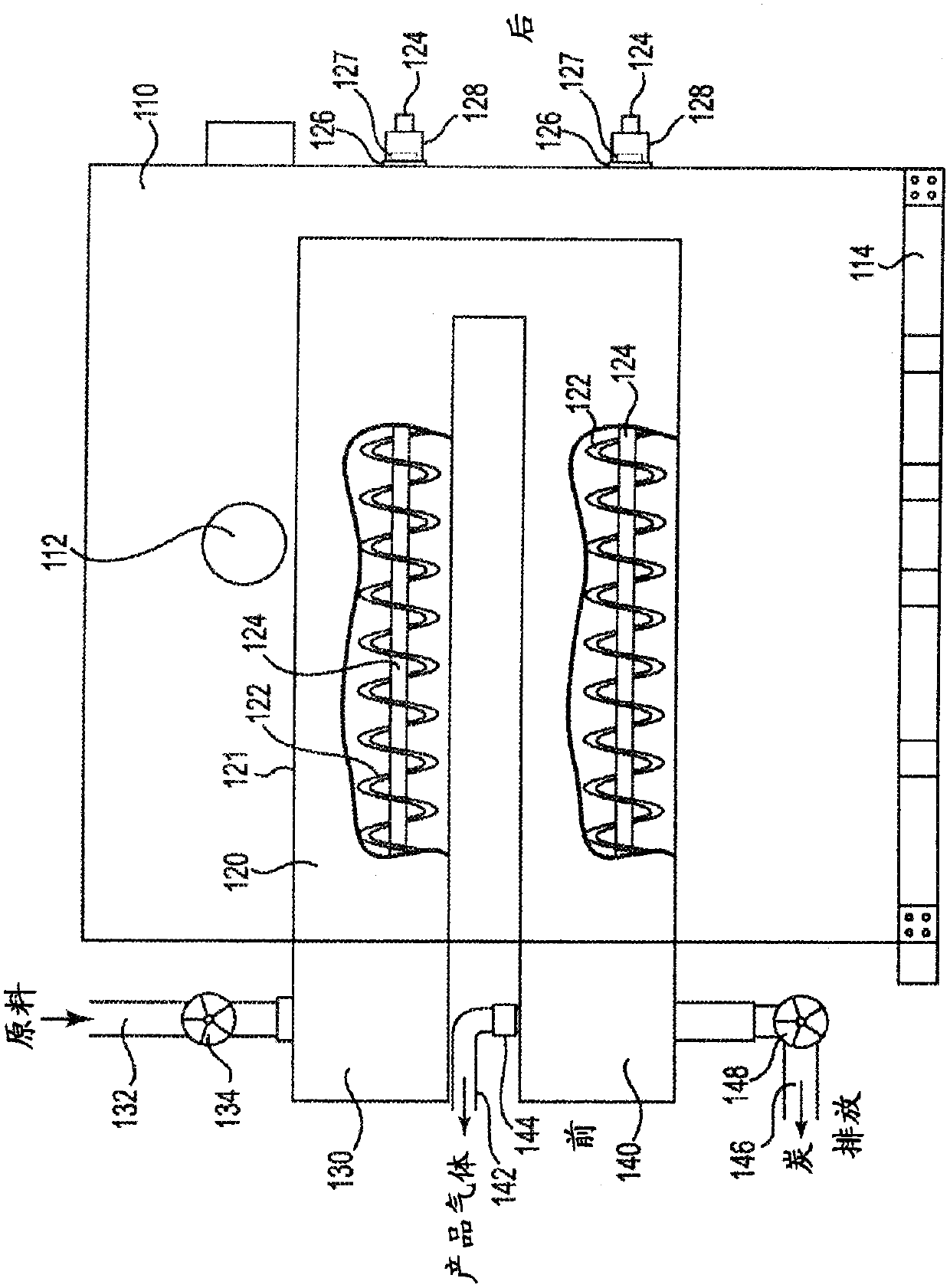

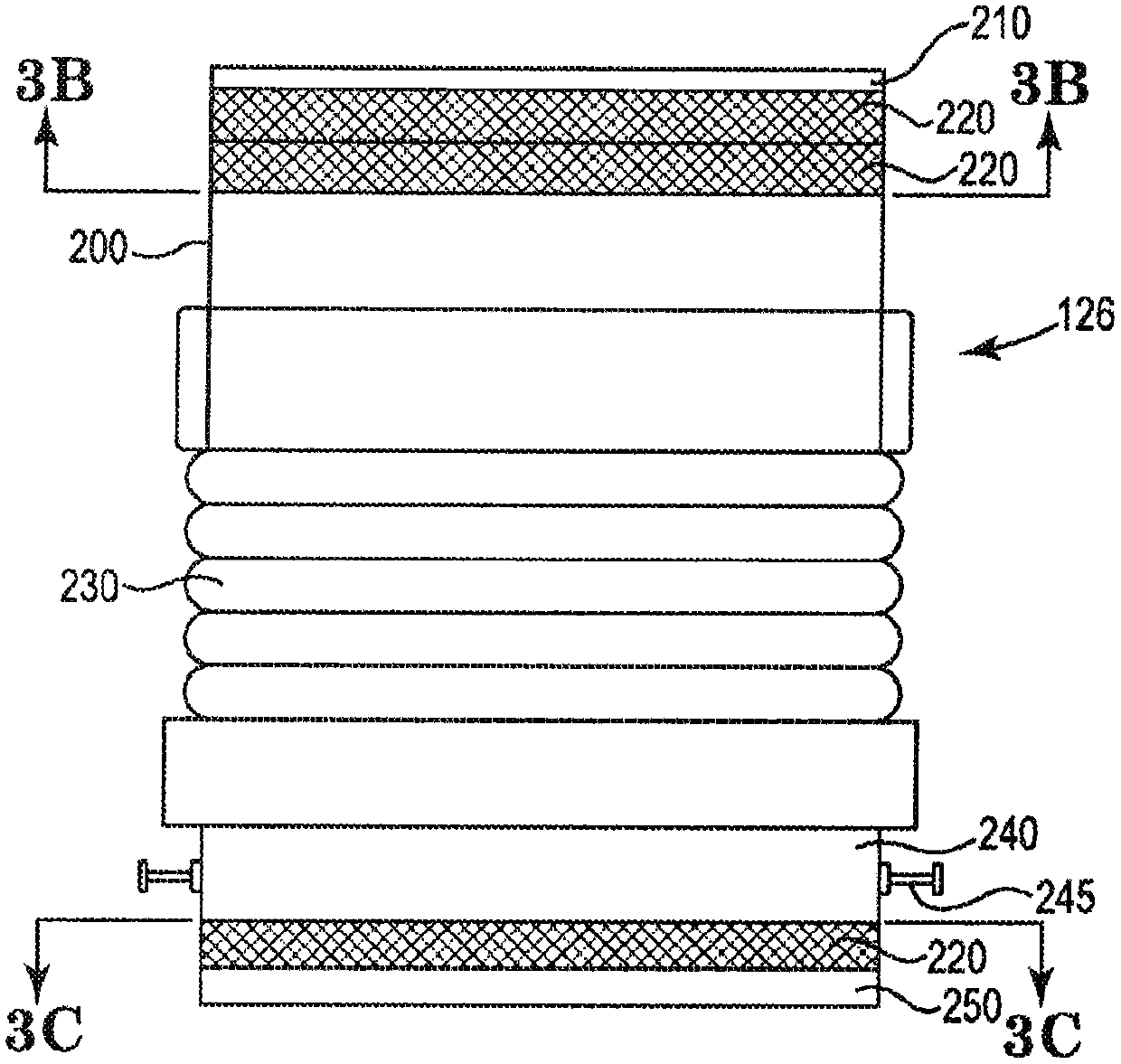

[0029] The following description relates to the process of processing a solid carbonaceous feedstock by a sublimation mechanism to a gaseous product fuel and a residual solid char fuel. The gaseous fuel is primarily methane, but can also include ethane, propane, and butane, depending on the nature of the solid carbonaceous feedstock and the residence time employed during the sublimation process. Solid charcoal fuels are solid carbon-based residues that cannot be converted into gaseous product fuels. For the purposes of this document, solid carbonaceous feedstocks exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com