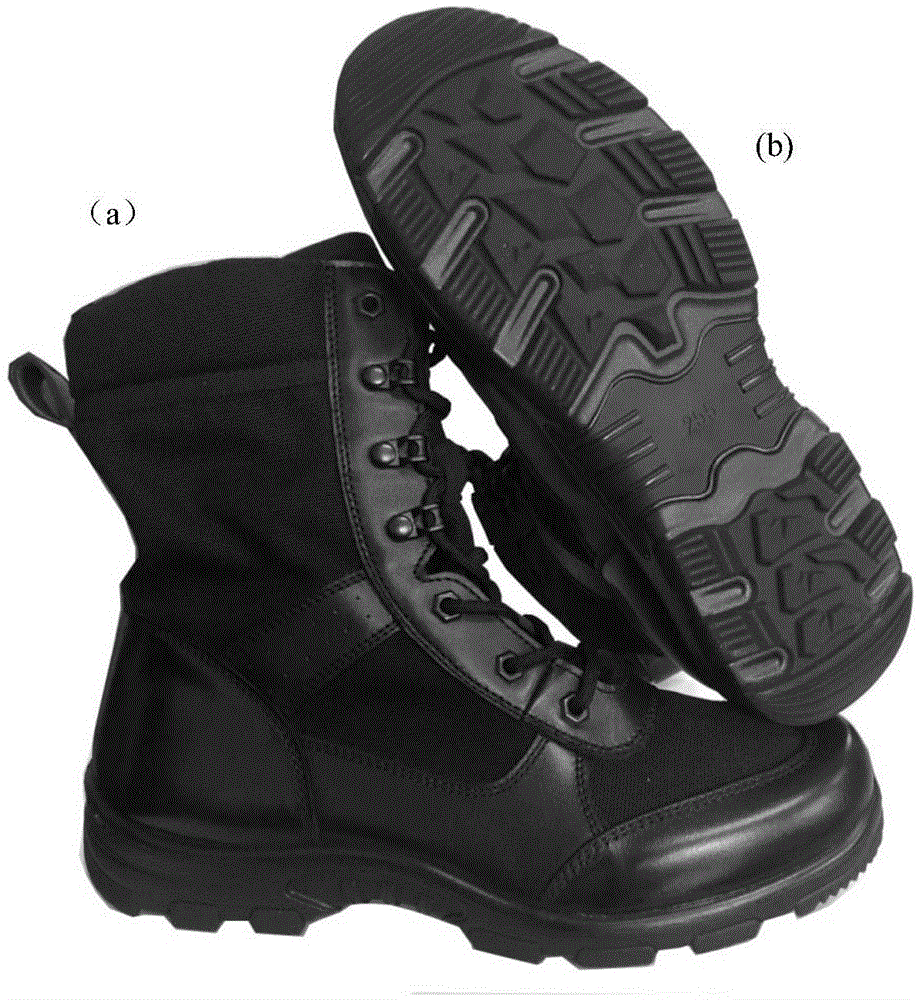

Protective boots and manufacturing method thereof

A technology for protective boots and boots, applied in applications, soles, clothing, etc., can solve the problems of lack of weather resistance, elasticity, durability, etc., and achieve the effect of reducing sole weight, reducing heel weight, and high wearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1, the preparation of end in polyurethane

[0085] 1. Polyurethane material is made of A and B components in the following parts by weight: the specific preparation method is as follows:

[0086] (1) Formula and production process of component A:

[0087] 1. Formula: A: Polyether 1 (Tianjin Petrochemical TED-28, molecular weight 3500-4500) 68.333 parts;

[0088] B: 15.889 parts of polyether 2 (KE-3704 of Kolia chemical, molecular weight is 5500~6500);

[0089] C: 8.111 parts of chain extender (1.4 butanediol);

[0090] D. 0.5 parts of foam stabilizer (Air Chemical LK221);

[0091] E. 2.5 parts of dispersant (n-dodecanethiol);

[0092] F. 1.333 parts of amine catalyst (air chemical industry A33);

[0093] G. 0.333 parts of water;

[0094] 2. Production process: Put the above raw materials into the reaction kettle in order, raise the temperature to 55-70 degrees, keep the temperature for 2 hours, take samples to test the acid value and hydroxyl value of t...

Embodiment 2

[0114] Embodiment 2, the preparation of rubber outsole

[0115] 1. The rubber material is made of the following components in parts by weight: 10 parts of styrene-butadiene solution; 28 parts of Japanese butadiene rubber; 5 parts of Vietnamese standard rubber SVR-3L; 20 parts of carbon black; 2.25 parts of zinc oxide; 0.42 parts of acid; 1.4 parts of active agent; 0.65 parts of accelerator; 0.8 parts of sulfur.

[0116] 2. Production process of rubber outsole:

[0117] 2.1. Weighing

[0118] Weigh all raw materials except adding accelerator according to the designed formula;

[0119] 2.2 Mixing

[0120] Mix the accurately weighed solution polystyrene butadiene, butadiene rubber and standard rubber SVR-3L raw materials, start the internal mixer to mix the materials evenly, add 2 / 3 of the amount of carbon black, and continue the internal mixing, rubber and carbon black Mix and re-agglomerate, when the temperature reaches 100°C, add all the remaining raw materials (E-I) and t...

Embodiment 3

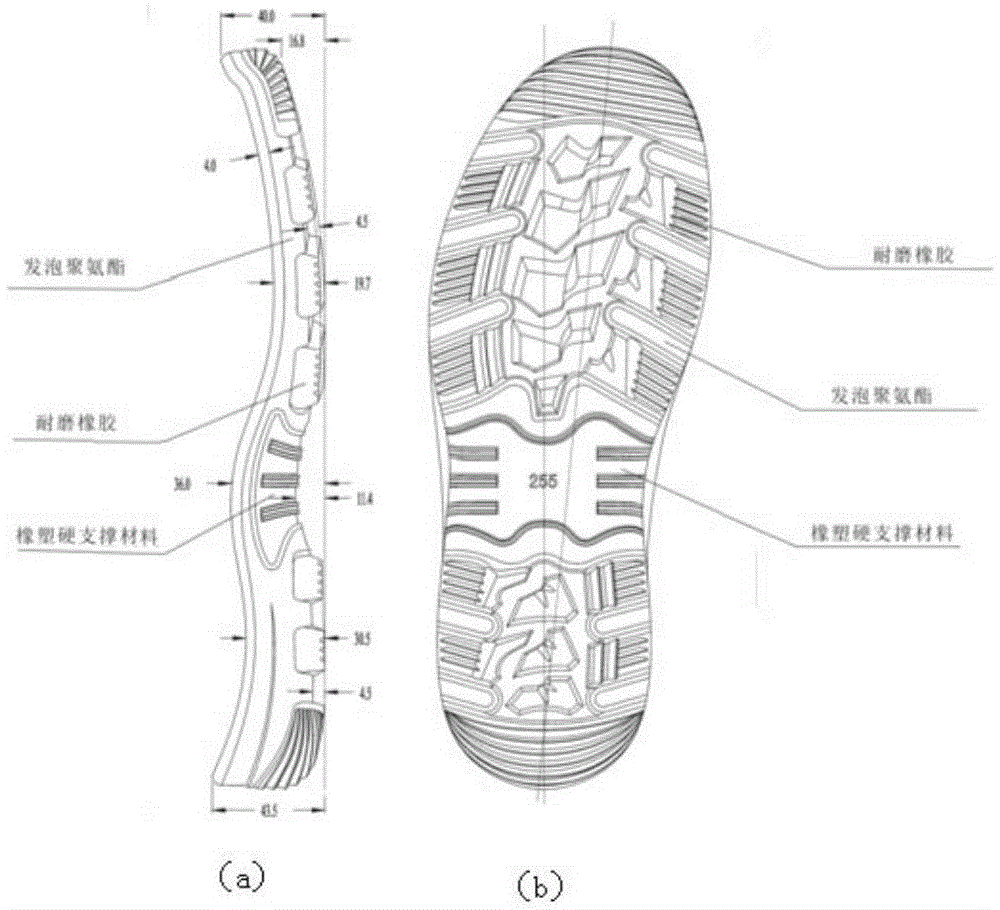

[0146] Embodiment 3, the preparation of protective boots

[0147] A preparation method for protective boots, comprising the steps of:

[0148] 1) Bonding of rubber outsole and waist support;

[0149] 2) The upper of the shoe is fluffed, the depth should not exceed 1 / 4 of the leather thickness, the upper is brushed with glue twice, and dried at 60°C for 2 to 3 minutes;

[0150] 3) Paste the shank on the waist of the shoe upper, and paste the polyurethane foam filler on the heel, which should be glued straight and firmly;

[0151] 4) Dry the shoe upper treated in step 2) at 80°C for 1 to 2 minutes, heat the rubber outsole at 80°C for 1 to 2 minutes, put the upper on the shoe last, straighten and flatten it;

[0152] 5) Apply glue evenly to the polyurethane film, and let it dry naturally at 25°C for 3-5 minutes;

[0153] Put the rubber outsole in the mold first, spread the polyurethane film on the outsole of the shoe, and lay it flat without wrinkles; the polyurethane film is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com