Composite bioactive factor freeze-drying method and composite bioactive factor freeze-dried powder

A bioactive factor and freeze-dried powder technology, which is applied in freeze-dried transportation, powder transportation, drug combination, etc., can solve unfavorable freeze-dried storage of composite bioactive factors, limit the use of composite bioactive factors, and reduce the activity of composite bioactive factors To achieve the effect of delaying skin aging, improving storage conditions, and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

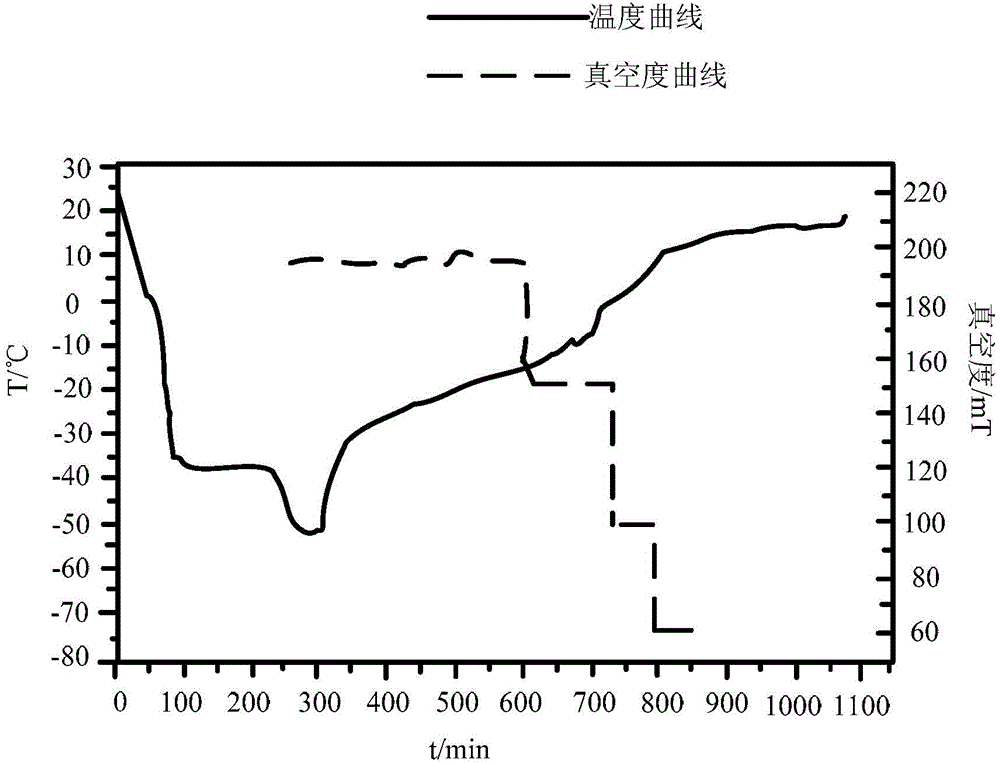

[0088] Take 10 parts of mannitol and mix with 10 parts of compound bioactive factor solution, and add purified water to 100 parts to obtain a mixed solution;

[0089] The mixed solution is sequentially subjected to pre-freezing, enhanced pre-freezing, sublimation drying and analytical drying (the specific process is the same as described above) to obtain the freeze-dried powder of the complex biologically active factor.

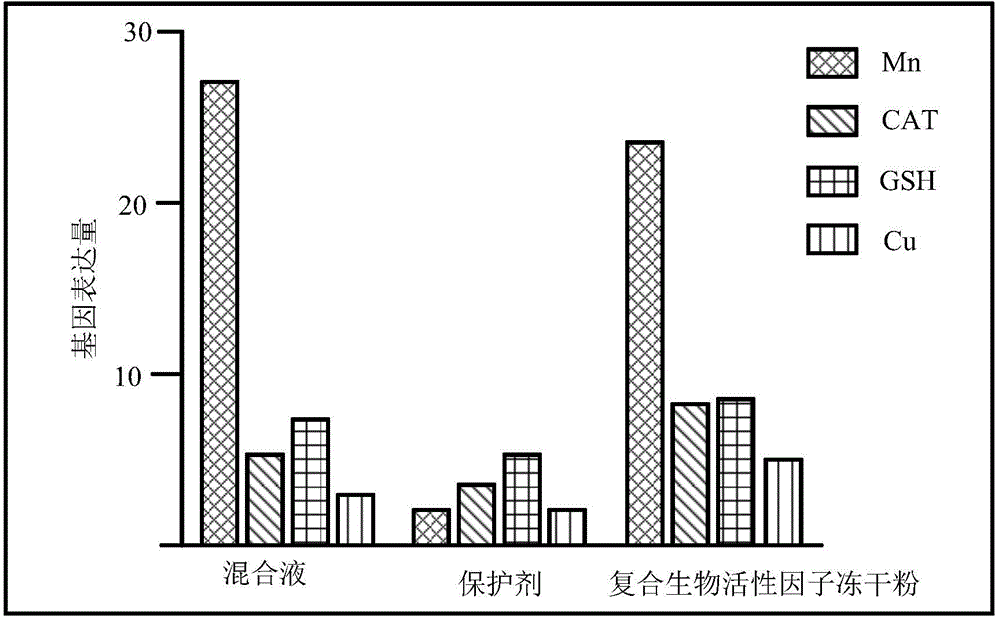

[0090] In conclusion, the obtained composite bioactive factor lyophilized powder comprises 10 parts of mannitol, 0.01 part of composite bioactive factor, and the composite bioactive factor keeps the activity of more than 75% of the bioactive factor in the composite bioactive factor solution in the gained freeze-dried powder, mainly are EGF, BFGF, VEGF, IGF1, IGF2, TGF-B1, TGF-B2, PDGF and KGF.

[0091] The obtained composite bioactive factor freeze-dried powder can be stored for 2 years at 2-8°C, and can be stored for 1-2 years at room temperature.

Embodiment 2

[0093] Mix 5 parts of sorbitol with 5 parts of complex bioactive factor solution, and add purified water to 100 parts to obtain a mixed solution;

[0094] The mixed solution is sequentially subjected to pre-freezing, enhanced pre-freezing, sublimation drying and analytical drying (the specific process is the same as described above) to obtain the freeze-dried powder of the complex biologically active factor.

[0095] Conclusion, gained compound bioactive factor freeze-dried powder comprises 5 parts of sorbitol, 0.005 part of compound biologically active factor, compound biologically active factor keeps the activity of more than 72% of the biologically active factor in the compound biologically active factor solution in the gained freeze-dried powder, mainly are EGF, BFGF, VEGF, IGF1, IGF2, TGF-B1, TGF-B2, PDGF and KGF.

[0096] The obtained composite bioactive factor freeze-dried powder can be stored at 2-8°C for 2 years, and stored at room temperature for 1-2 years.

Embodiment 3

[0098] Take 8 parts of the mixture of sorbitol and mannitol (the specific ratio can be arbitrary), 0.5 part of trehalose, 0.6 part of dextran 40, mix with 5 parts of the compound biologically active factor solution, and add purified water to 100 parts to obtain a mixed solution ;

[0099] The mixed solution is sequentially subjected to pre-freezing, enhanced pre-freezing, sublimation drying and analytical drying (the specific process is the same as described above) to obtain the freeze-dried powder of the complex biologically active factor.

[0100] In conclusion, the obtained composite bioactive factor lyophilized powder contains 8 parts of sorbitol and mannitol, 0.5 part of trehalose, 0.6 part of dextran 40, and 0.005 part of the composite bioactive factor, and the composite bioactive factor in the obtained freeze-dried powder maintains the composite biological activity More than 78% of the biologically active factors in the factor solution are mainly EGF, BFGF, VEGF, IGF1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com