Preparation method of low-carbon alkane dehydrogenation catalyst

A technology of dehydrogenation catalyst and low-carbon alkanes, which is applied in the direction of hydrocarbons, hydrocarbons, molecular sieve catalysts, etc., and can solve the problems of no industrialization examples of aerobic dehydrogenation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

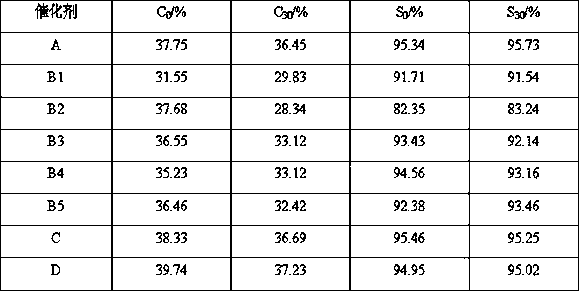

Examples

Embodiment 1

[0036] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 50% and a silicon-aluminum ratio of 100, mix it with 350g of alumina, 25g of turnip powder and 50g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The molded carrier was dried in the shade for 24 hours, then dried in an oven at 110° C. for 12 hours, and then baked in a muffle furnace at 600° C. for 6 hours. After cooling, the broken growth length is 2~5mm, and 50ml of the carrier is measured, impregnated with Sn, the catalyst-promoting component, and tin tetrachloride is selected as the precursor, and the Sn-containing carrier is obtained by drying and roasting. It was placed in a rotary evaporator and vacuumed for 30 min.

[0037] Preparation of impregnating solution: appropriate amount of ZnCl 2 Dissolve in 20ml of deionized water, and dropwise add 6ml of ammonia water with a mass concentration of 25% to it, and stir thoroughl...

Embodiment 2

[0053] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 70% and a silicon-aluminum ratio of 100, mix it with 400g of alumina, 25g of turnip powder and 50g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The formed carrier was dried in the shade for 24 hours, then dried in an oven at 110°C for 10 hours, and then baked in a muffle furnace at 600°C for 7 hours. After cooling, the broken growth length is 2~5mm, and 50ml of the carrier is measured, impregnated with Sn, the catalyst-promoting component, and tin tetrachloride is selected as the precursor, and the Sn-containing carrier is obtained by drying and roasting. It was placed in a rotary evaporator and vacuumed for 30 min.

[0054] Preparation of impregnation solution: appropriate amount of ZnCl 2 Dissolve in 20ml of deionized water, and dropwise add 31ml of ammonia water with a mass concentration of 15% to it, and stir thoroughly a...

Embodiment 3

[0057] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 60% and a silicon-aluminum ratio of 150, mix it with 350g of alumina, 25g of turnip powder and 50g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The formed carrier was dried in the shade for 24 hours, then dried in an oven at 110°C for 10 hours, and then baked in a muffle furnace at 600°C for 7 hours. After cooling, the broken growth length is 2~5mm, and 50ml of the carrier is measured, impregnated with Sn, the catalyst-promoting component, and tin tetrachloride is selected as the precursor, and the Sn-containing carrier is obtained by drying and roasting. It was placed in a rotary evaporator and vacuumed for 60 min.

[0058] Preparation of impregnation solution: appropriate amount of ZnCl 2Dissolve in 25ml of deionized water, and dropwise add 28ml of ammonia water with a mass concentration of 20% to it, and stir thoroughly af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com