Manufacturing method for motion sensor of micro-electro-mechanical system

A motion sensor and micro-electro-mechanical system technology, applied in the field of micro-electro-mechanical systems, can solve problems that threaten the reliability of micro-machines and complex operations, and achieve the effects of low cost, simple preparation process, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

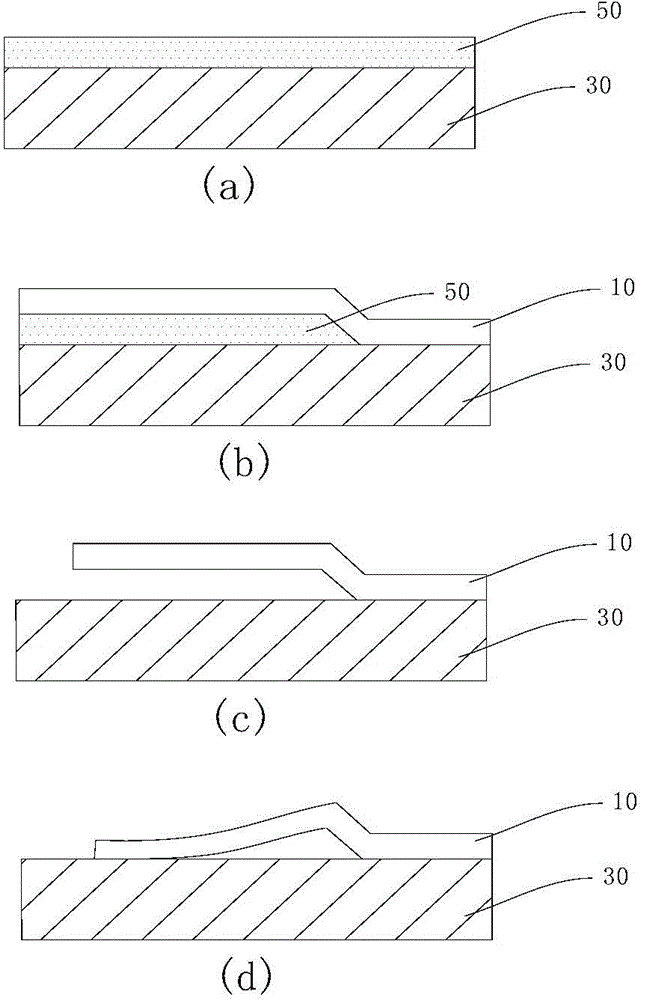

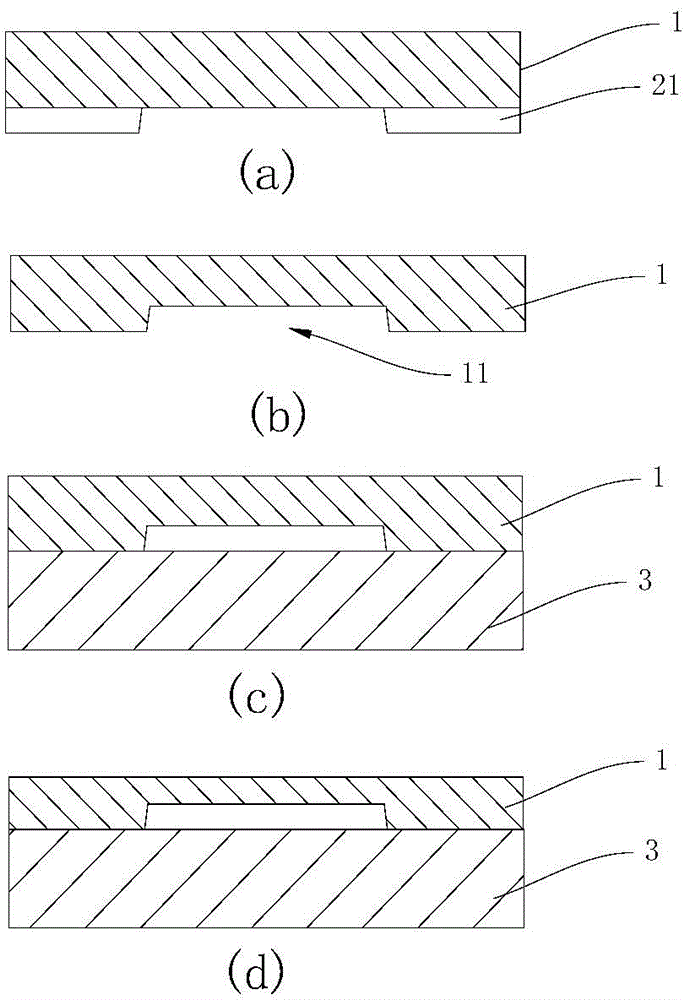

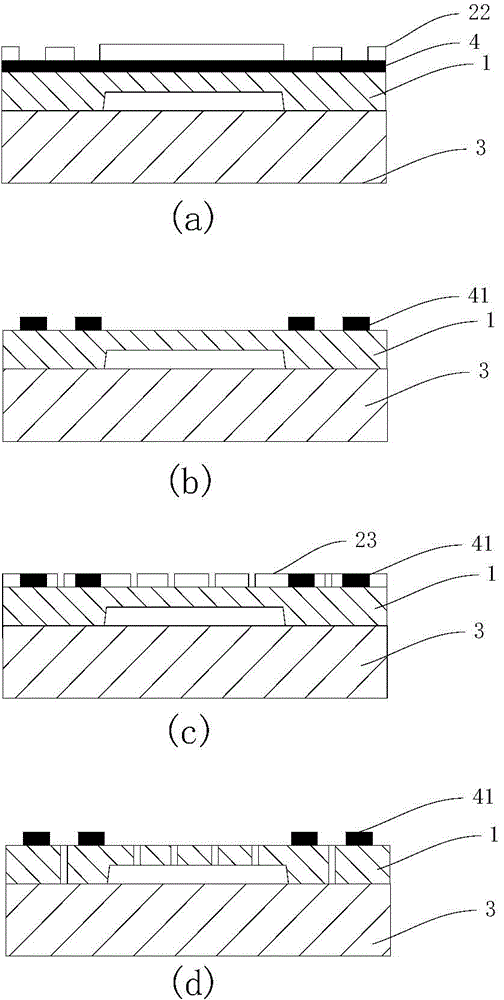

[0022] The present invention provides a method for preparing a micro-electromechanical system motion sensor, for example, it can be used to form a micro-mechanical inertial sensor, and its detailed process is described as figure 2 Shown:

[0023] Step 1: Select a highly doped single crystal silicon wafer 1 as the material of the structural layer. The highly doped single crystal silicon is for improving the conductivity of silicon, and there is no limitation on the doping elements. The fracture strength of single crystal silicon is high, which can make the cantilever beam quality block have good fatigue life when it vibrates. In addition, highly doped silicon also has good electrical conductivity.

[0024] The silicon wafer 1 is cleaned to remove organic pollutants and metal impurities on the surface. Use the photolithography process to carry out t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap