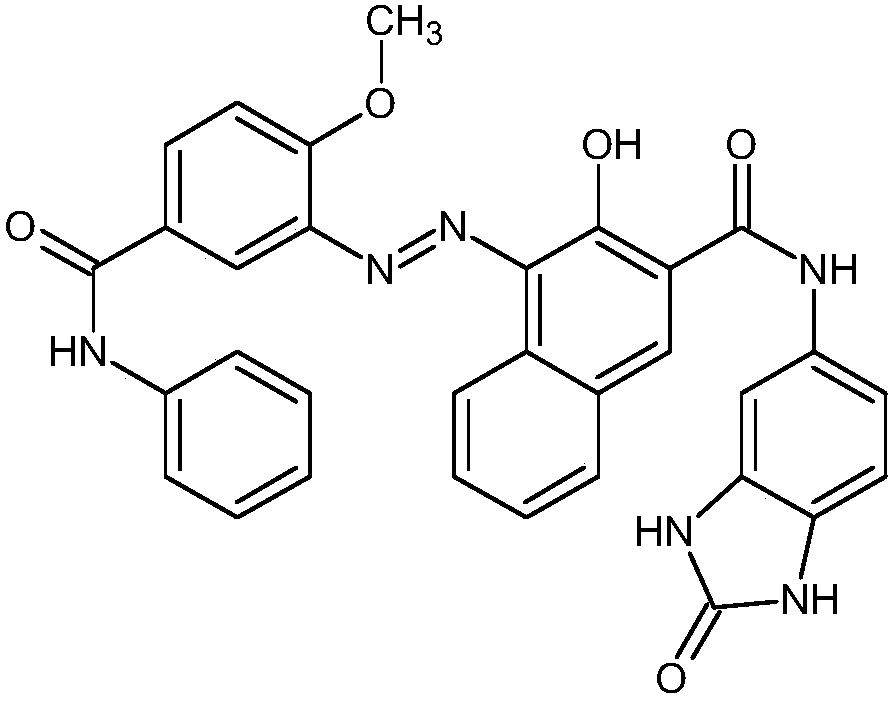

A kind of preparation method of c.i. pigment red 176

A technology of pigment red and methoxyanilide, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of reducing pigment application performance and increasing costs, and achieve excellent dispersibility, improve quality, and The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Add 1000kg of water and 160kg of 30% hydrochloric acid into the diazo pot, add 150kg of dried 3-amino-4-methoxyanilide under stirring, beat for 1 hour, cool down to below 0°C with ice, and adjust the volume to 2500L. Add 40% sodium nitrite dissolved in advance (dry 42.5kg sodium nitrite plus 64kg water), measure the end point to keep the potassium iodide starch test paper slightly blue, keep the temperature at 5-10°C, stir for 30 minutes, add 20kg diatomaceous earth, After stirring for 20 minutes, the diazonium salt solution was obtained by filtration.

[0051] Add a small amount of water into the coupling pot, start stirring, and add 186.5kg of 5-(2'-hydroxy-3'-naphthylcarboxamido)-2-benzimidazolone into the coupling pot with water through a colloid mill, and add 0.6kg Stearyl polyoxyethylene ether, beat for 0.5 hours, adjust the volume to 1500L, and adjust the temperature to 0-10°C.

[0052] The diazonium salt solution is slowly added to the beaten 5-(2'-hydroxyl-3'-...

Embodiment 2

[0055] Add 1000kg of water and 220kg of 30% hydrochloric acid into the diazo pot, add 150kg of dried 3-amino-4-methoxyanilide under stirring, beat for 1 hour, cool down to below 0°C with ice, and adjust the volume to 2500L. Add 40% sodium nitrite dissolved in advance (45kg dry sodium nitrite plus 68kg water), measure the end point to keep the potassium iodide starch test paper slightly blue, keep the temperature at 5-10°C, stir for 1 hour, add 20kg diatomaceous earth, stir After 20 minutes, the diazonium salt solution was obtained by filtration.

[0056] Add a small amount of water into the coupling pot, start stirring, add 200kg of 5-(2'-hydroxy-3'-naphthylcarboxamido)-2-benzimidazolone into the coupling pot through a colloid mill, and add 1kg of methyl Sodium naphthalenesulfonate formaldehyde condensate MF, beat for 0.5 hours, adjust the volume to 1500L, and adjust the temperature to 0-10°C.

[0057] The diazonium salt solution is slowly added to the beaten 5-(2'-hydroxyl-3...

Embodiment 3

[0060] Add 1000kg of water and 200kg of 30% hydrochloric acid into the diazonium pot, add 150kg of dried 3-amino-4-methoxyanilide under stirring, beat for 1 hour, cool down to below 0°C with ice, adjust the volume to 2500L, Add 40% sodium nitrite dissolved in advance (43kg dry sodium nitrite plus 65kg water), measure the end point to keep the potassium iodide starch test paper slightly blue, keep the temperature at 5-10°C, stir for 1 hour, add 20kg diatomaceous earth, stir After 20 minutes, the diazonium salt solution was obtained by filtration.

[0061] Add a small amount of water into the coupling pot, start stirring, add 190kg of dried 5-(2'-hydroxy-3'-naphthylcarboxamido)-2-benzimidazolone into the coupling pot through a colloid mill, add 0.8kg of octane Base phenol polyoxyethylene ether emulsifier OP, beat for 0.5 hours, adjust the volume to 1500L, and adjust the temperature to 0-10°C.

[0062] The diazonium salt solution is slowly added to the beaten 5-(2'-hydroxyl-3'-n...

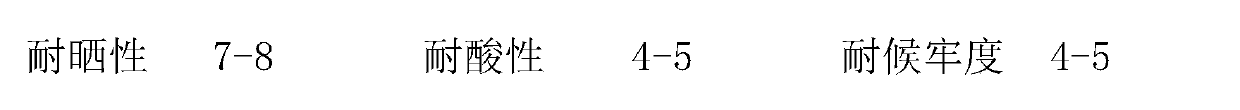

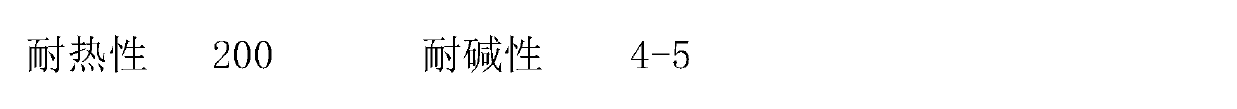

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| photostability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com