Blue-light-barrier anti-dazzle optical film and preparation method therefor

A technology for blocking blue light and optical film, applied in the direction of film/flake adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problems of retinal damage, visual fatigue, human eyesight damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

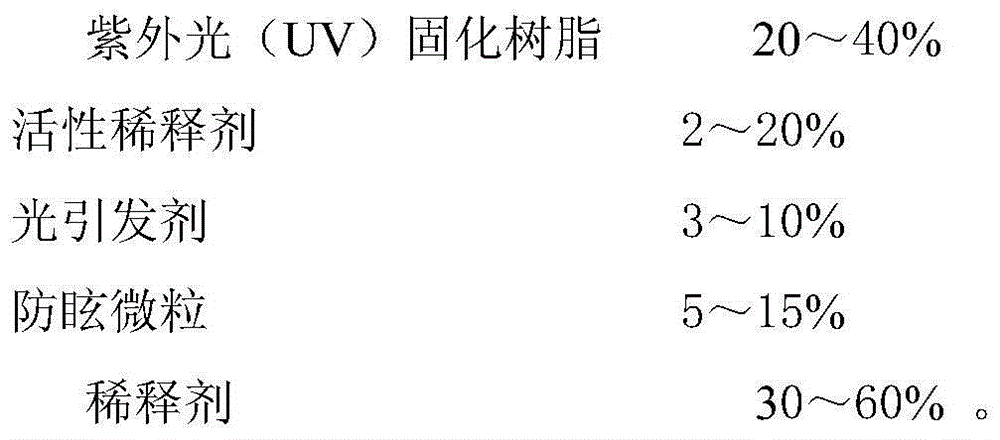

[0024] Preparation of anti-glare and scratch-resistant coating coating solution: polyurethane acrylate resin, 25%; silicone modified acrylate resin, 5%; tripropylene glycol diacrylate TPGDA, 2%; polymethyl methacrylate resin particles 10 %; Irgacure 184, 8%; 1 / 1 Toluene / Propylene Glycol Methyl Ether, 50%.

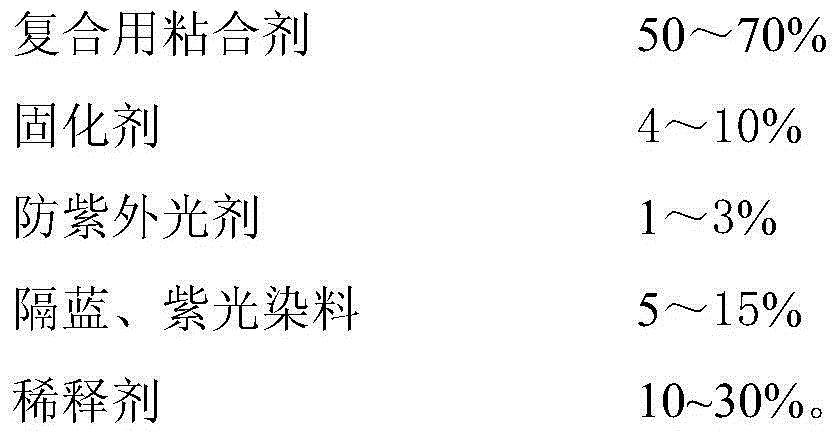

[0025] Prepare composite adhesive layer coating solution: polyurethane composite adhesive, 60%; HDI trimer, 6%; anti-ultraviolet light agent, 3%; blue and purple dyes, 8%; ethyl acetate, 23%.

[0026] Prepare the pressure-sensitive adhesive layer coating solution: silicone pressure-sensitive adhesive, 70%; ultraviolet light absorber, 1%; 1 / 1 toluene / butanone, 29%.

[0027] Preparation method: Using precision coating equipment, in a thousand-class clean environment, a roll-type clean transparent film is coated with anti-glare and scratch-resistant coating liquid through precision coating equipment, and dried by hot air at 70 ° C to 100 ° C. Energy 100~500mj / cm 2 After the ...

Embodiment 2

[0029] Prepare anti-glare and scratch-resistant coating coating solution: polyurethane acrylate resin, 20%; silicone modified acrylate resin, 8%; pentaerythritol triacrylate PETA, 3%; polystyrene resin particles 12%; Irgacure184, 7%; 1 / 1 toluene / butyl acetate, 50%.

[0030] Preparation of composite adhesive layer coating solution: polyurethane composite adhesive, 60%; HDI biuret, 6%; anti-ultraviolet light agent, 3%; blue and purple dyes, 8%; ethyl acetate, 23%.

[0031] Prepare the pressure-sensitive adhesive layer coating solution: silicone pressure-sensitive adhesive, 70%; ultraviolet light absorber, 1%; 1 / 1 toluene / butanone, 29%.

[0032] The preparation method is as in Example 1. The thickness of the anti-glare layer is 5 μm, that of the composite adhesive layer is 25 μm, and that of the pressure-sensitive adhesive layer is 20 μm.

Embodiment 3

[0034] Prepare anti-glare and scratch-resistant coating coating liquid: polyurethane acrylate resin, 20%; polyester acrylate resin, 5%; tripropylene glycol diacrylate TPGDA, 2%; polymethyl methacrylate resin particles 15%; Irgacure 184, 8%; 1 / 1 toluene / propylene glycol methyl ether, 50%.

[0035] Prepare composite adhesive layer coating solution: polyurethane composite adhesive, 55%; HDI trimer, 6%; anti-ultraviolet light agent, 3%; blue and purple dyes, 11%; ethyl acetate, 25%.

[0036] Prepare the pressure-sensitive adhesive layer coating solution: silicone pressure-sensitive adhesive, 70%; ultraviolet light absorber, 1%; 1 / 1 toluene / butanone, 29%.

[0037] The preparation method is as in Example 1. The thickness of the anti-glare layer is 5 μm, that of the composite adhesive layer is 15 μm, and that of the pressure-sensitive adhesive layer is 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com