Sulfur arsenic purifying agent and its use

A purifying agent, weight percentage technology, applied in organic chemistry, other chemical processes, adsorption purification/separation, etc., can solve the problems of high industrial application cost, low sulfur arsenic content, high bulk density of sulfur arsenic purifying agent, and achieve industrial application. The effect of low cost, high arsenic content, and improved purification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

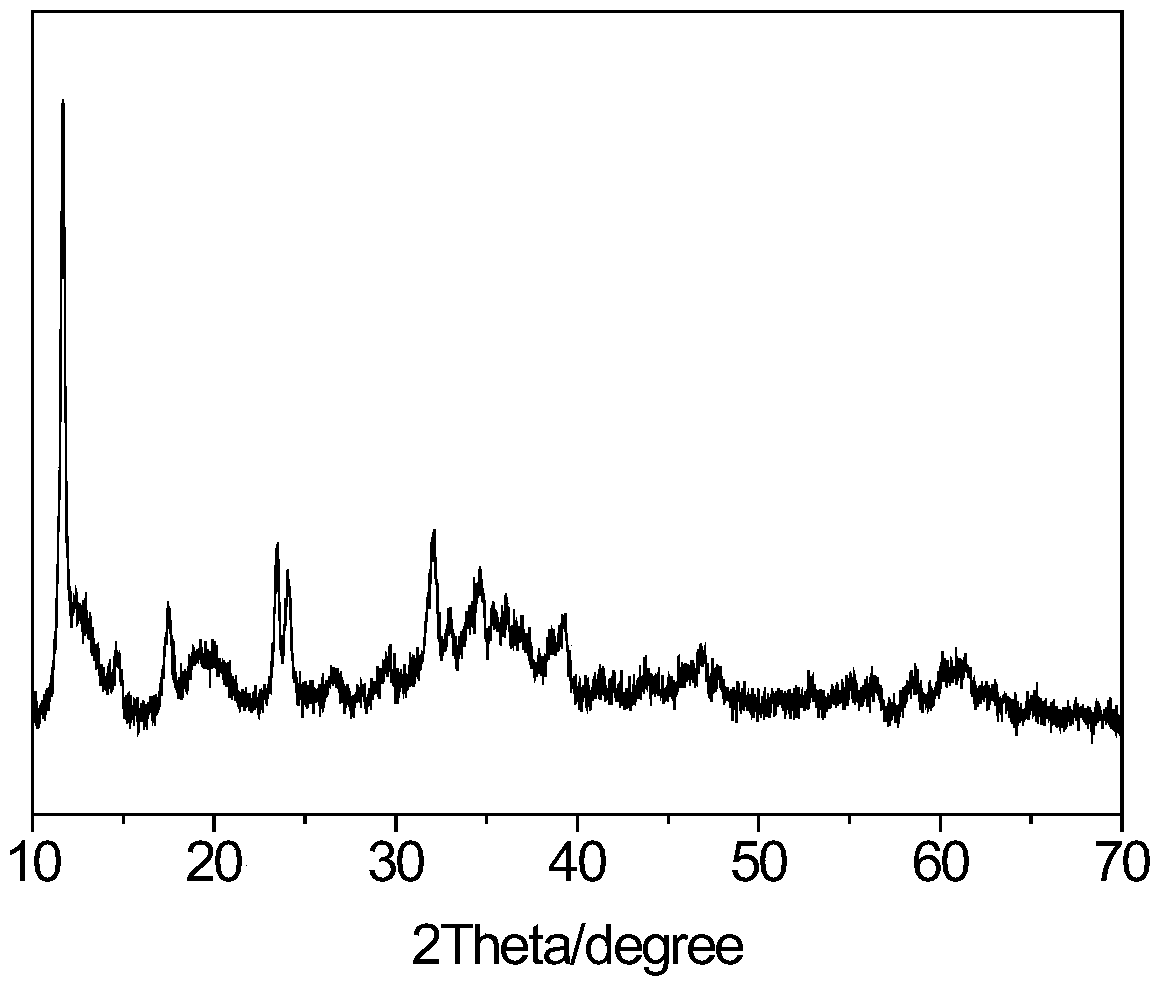

Image

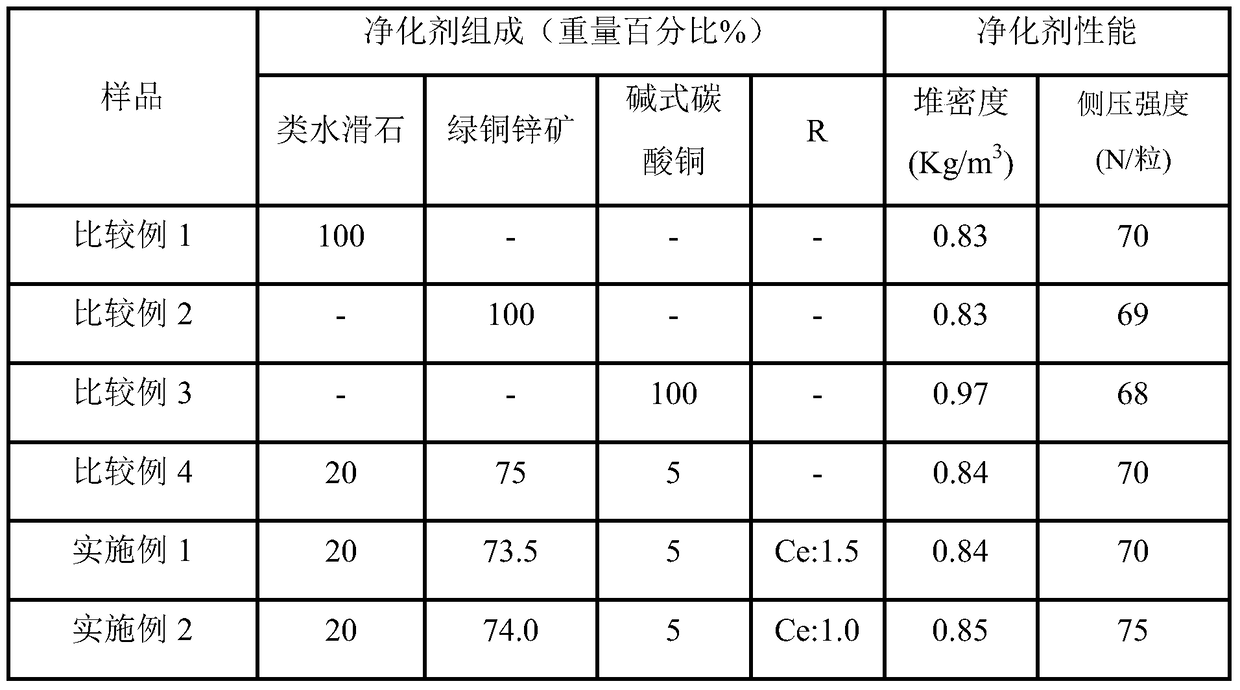

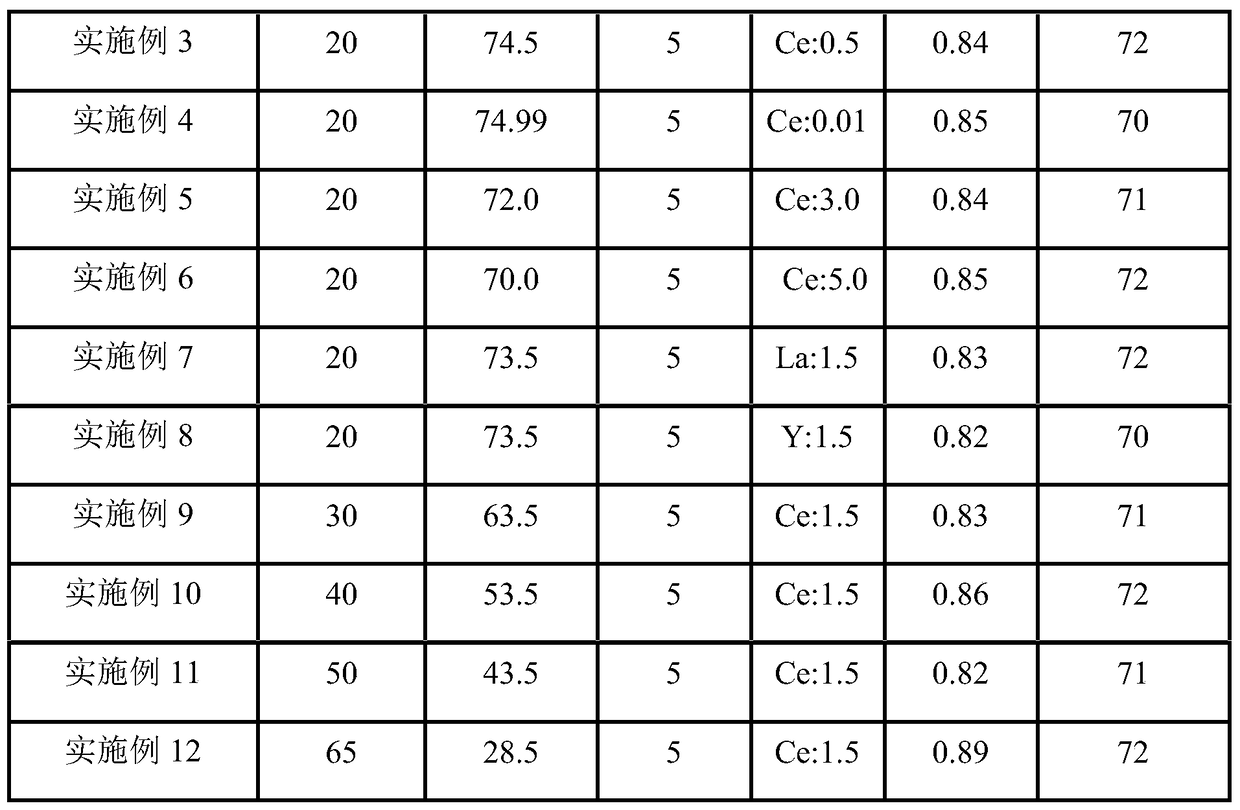

Examples

Embodiment 1

[0033] 55 grams of zinc nitrate, 45 grams of copper nitrate, 12 grams of aluminum nitrate, 1.2 grams of cerium nitrate and 450 grams of water were mixed and stirred evenly to obtain a metal salt solution, and 49 grams of sodium carbonate and 550 grams of water were mixed to obtain a sodium carbonate solution. The sodium solution is fully mixed with the metal salt solution, the pH value of the solution is adjusted to 7.0 with 1% by weight of sodium carbonate, reacted at 70° C. for 1 hour, the precipitate is washed and dried, and then 10 grams of aluminum oxide and 1 gram of graphite are added to mix and roll. Based on the total weight percentage of the precipitate and graphite, 30% by weight of water was added, granulated, dried, and pressed into tablets to obtain the sample composition shown in Table 1.

Embodiment 2

[0035] 55 grams of zinc nitrate, 45 grams of copper nitrate, 12 grams of aluminum nitrate, 0.8 grams of cerium nitrate and 450 grams of water were mixed and stirred evenly to obtain a metal salt solution, and 49 grams of sodium carbonate and 550 grams of water were mixed to obtain a sodium carbonate solution. The sodium solution is fully mixed with the metal salt solution, the pH value of the solution is adjusted to 7.0 with 1% by weight of sodium carbonate, reacted at 70° C. for 1 hour, the precipitate is washed and dried, and then 10 grams of aluminum oxide and 1 gram of graphite are added to mix and roll. Based on the total weight percentage of the precipitate and graphite, 30% by weight of water was added, granulated, dried, and pressed into tablets to obtain the sample composition shown in Table 1.

Embodiment 3

[0037] 55 grams of zinc nitrate, 45 grams of copper nitrate, 12 grams of aluminum nitrate, 0.4 grams of cerium nitrate and 450 grams of water were mixed and stirred to obtain a metal salt solution, and 49 grams of sodium carbonate and 550 grams of water were mixed to obtain a sodium carbonate solution. The sodium solution is fully mixed with the metal salt solution, the pH value of the solution is adjusted to 7.0 with 1% by weight of sodium carbonate, reacted at 70° C. for 1 hour, the precipitate is washed and dried, and then 10 grams of aluminum oxide and 1 gram of graphite are added to mix and roll. Based on the total weight percentage of the precipitate and graphite, 30% by weight of water was added, granulated, dried, and pressed into tablets to obtain the sample composition shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com