Preparing method for improving Mo alloy performance by adding Ti

A performance and alloy technology, applied in the preparation field of adding Ti to improve the performance of Mo alloy, can solve the problems of low strength, less follow-up processing, high material utilization rate, etc., achieve high tensile strength, increase tensile strength, and refine particles organization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: a kind of preparation method that adds Ti to improve Mo alloy performance, comprises the following steps:

[0017] (1) Ingredients: Mo powder, oxygen content is 0.13%, high-purity TiH 2 pink,;

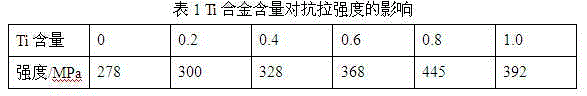

[0018] (2) Make mixed powder: add TiH to Mo powder 2 The powder is made into Mo-Ti mixed powder, and the Ti mass fraction is 0.6~1% Mo-Ti mixed powder;

[0019] (3) Under the pressure of 300MPa, it is formed by steel mold pressing;

[0020] (4) Pre-sintering: in H 2 Under atmosphere, pre-fire at 1000°C for 2h;

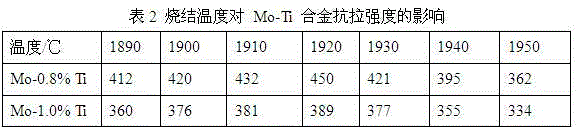

[0021] (5) High temperature sintering: in H 2 Carry out high-temperature sintering under protection, the sintering temperature is 1890~1950°C, and the holding time is 3h.

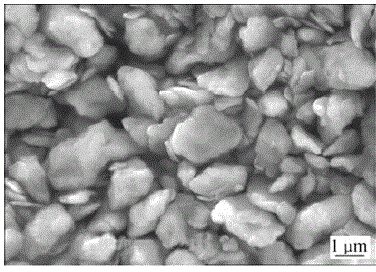

[0022] The particle size of the Mo powder used in the step (1) is below 3.5 μm.

[0023] The particle size of the TiH2 powder used in the step (1) is below 50 μm.

[0024] In the step (2), Ti-Mo mixed powder with a mass fraction of Ti of 0.8% is added.

[0025] In the step (2), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com