A method for preparing a high-temperature-resistant high-damping composite coating on the surface of an aerospace alloy

An aerospace alloy and composite coating technology, which is applied to the surface coating liquid device, metal material coating process, coating, etc., can solve the problems of increased thermal stress and reduced processing efficiency, and achieves increased elastic modulus, Effect of improving bonding strength and improving elastic recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

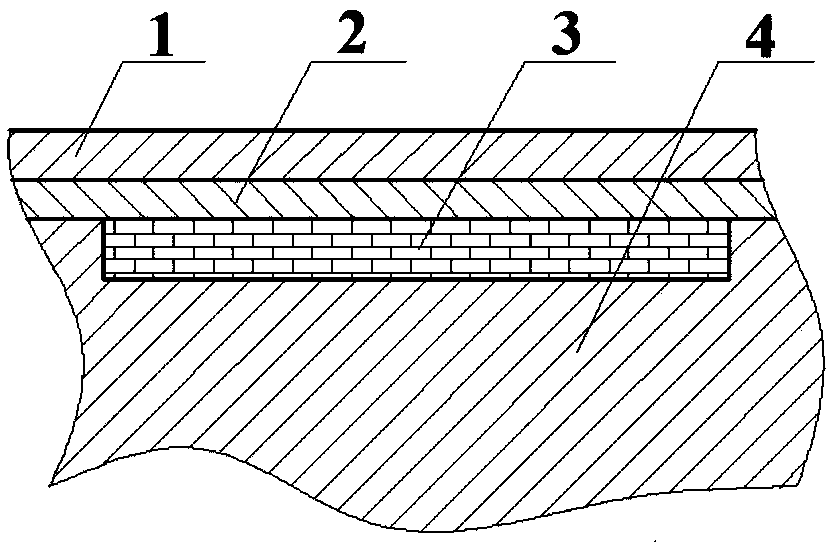

Image

Examples

Embodiment 1

[0032] Step 1: Grind and polish the surface of the TC6 titanium alloy sample (120mm×25mm×2mm), and use alcohol as a solvent to clean it ultrasonically for 20 minutes, then take it out and dry it naturally;

[0033] Step 2: Mix butyl rubber and chlorinated butyl rubber according to a certain ratio for 90 seconds, then add various auxiliary materials and mix for 120 seconds, and finally add sulfur, mix for 60 seconds to vulcanize and form, and refine to form a viscoelastic high-damping coating; The viscoelastic high damping coating is coated on the surface of the sample as an absorbing layer, and K9 glass is used as a constrained layer for laser micro-modeling. The micro-modeling area is 100mm×15mm and the depth is 80um. The pit is a square with a side length of 100um, and the overlap rate is 10%;

[0034] Step 3: Repeatedly coat the viscoelastic high damping paint on the laser micro-sculpting area with a coating thickness of 80um, keep the coated surface smooth and clean, and t...

Embodiment 2

[0040] Step 1: Grind and polish the surface of the 2024-T351 aluminum alloy sample (120mm×25mm×2mm), and use alcohol as a solvent to clean it ultrasonically for 20 minutes, then take it out and dry it naturally;

[0041] Step 2: Mix polyurethane and chlorinated butyl rubber according to a certain ratio for 120s, then add various auxiliary materials and mix for 120s, finally add sulfur, knead for 60s to vulcanize and form, and refine to form a viscoelastic high-damping coating; The prepared viscoelastic high damping coating is coated on the surface of the sample as an absorbing layer, and K9 glass is used as a constrained layer for laser micro-modeling. The micro-modeling area is 100mm×20mm and the depth is 50um. Among them, the micro-pit It is a circle with a diameter of 100um, and the overlap rate is 50%;

[0042] Step 3: Repeatedly coat the viscoelastic high damping paint on the laser micro-sculpting area with a coating thickness of 50um, keep the coated surface smooth and c...

Embodiment 3

[0048] Step 1: Grind and polish the surface of the IN718 nickel-based alloy sample (120mm×25mm×2mm), and use alcohol as a solvent to clean it ultrasonically for 20 minutes, then take it out and dry it naturally;

[0049] Step 2: Mix polyurethane and butyl rubber according to a certain ratio for 90s, then add various auxiliary materials and mix for 120s, and finally add sulfur, knead for 90s to vulcanize and form, and refine it into a viscoelastic high-damping coating; The viscoelastic high-damping coating is coated on the surface of the sample as an absorbing layer, and K9 glass is used as a constrained layer for laser micro-modeling. The micro-modeling area is 100mm×20mm and the depth is 100um. The micro-pit is 100um ×50um rectangle, the overlap rate is 20%;

[0050] Step 3: Repeatedly coat the viscoelastic high damping paint on the laser micro-sculpting area with a coating thickness of 100um, keep the coated surface smooth and clean, and then let it dry naturally;

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com