A kind of high-strength corrosion-resistant zirconium-containing stainless steel and its preparation method

A corrosion-resistant, high-strength technology, applied in the field of materials, can solve the problems of stainless steel strength, corrosion resistance, harsh service environment, cumbersome preparation process, etc., to achieve excellent microstructure, improve mechanical properties and corrosion resistance Obvious effects of performance and tissue refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a method for preparing high-strength corrosion-resistant zirconium-containing stainless steel described in the above technical solution, comprising the following steps:

[0038] (1) The raw materials are smelted multiple times to obtain alloy ingots, the raw materials include C source, Si source, Mn source, Cr source, Ni source, Mo source, Zr source, Hf source, Ti source and Fe source;

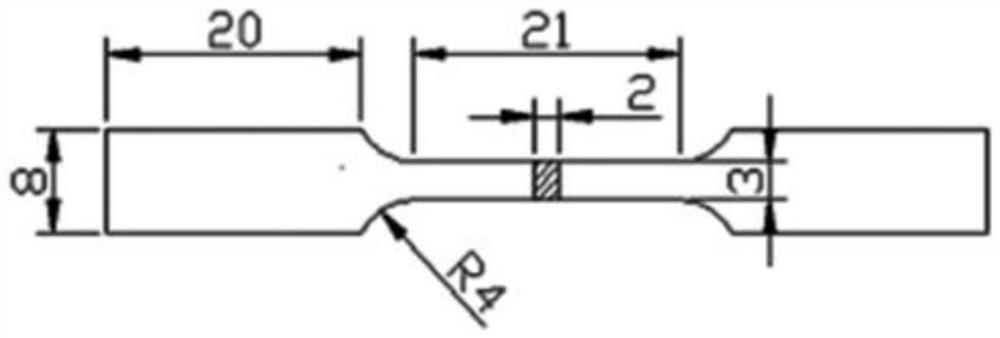

[0039] (2) heating the alloy ingot described in step (1) to the hot rolling temperature for hot rolling treatment to obtain the alloy plate;

[0040] (3) The alloy plate described in step (2) is subjected to solution treatment and then quenched to obtain a high-strength corrosion-resistant zirconium-containing stainless steel.

[0041]In the invention, C source, Si source, Mn source, Cr source, Ni source, Mo source, Zr source, Hf source, Ti source and Fe source are smelted multiple times to obtain alloy ingots. In the present invention, the melting temper...

Embodiment 1

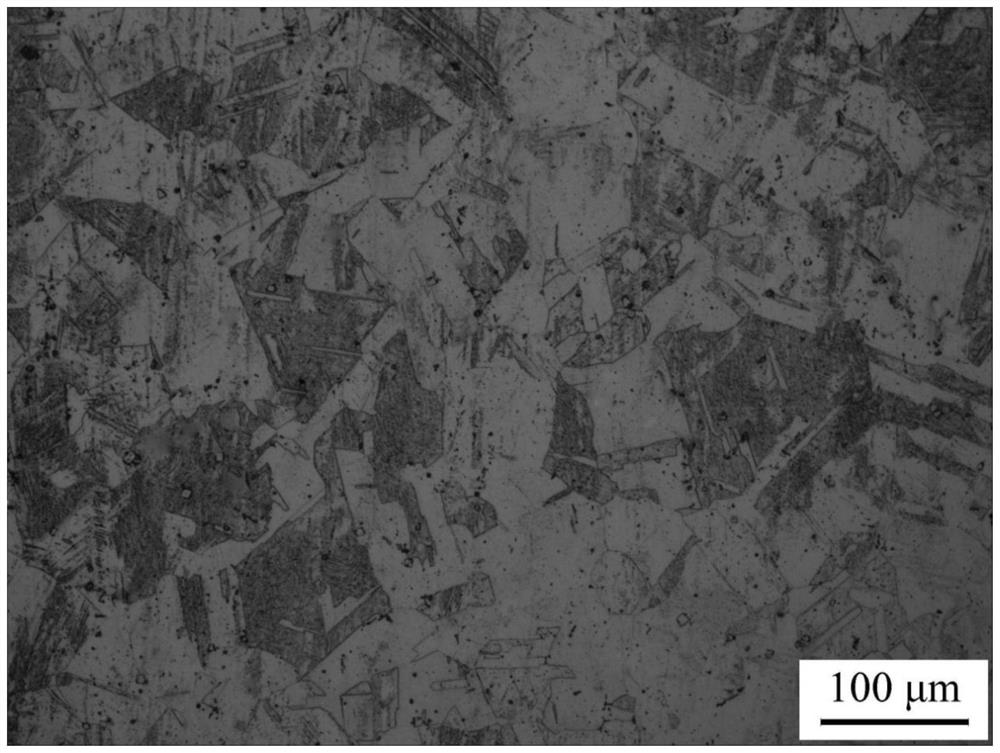

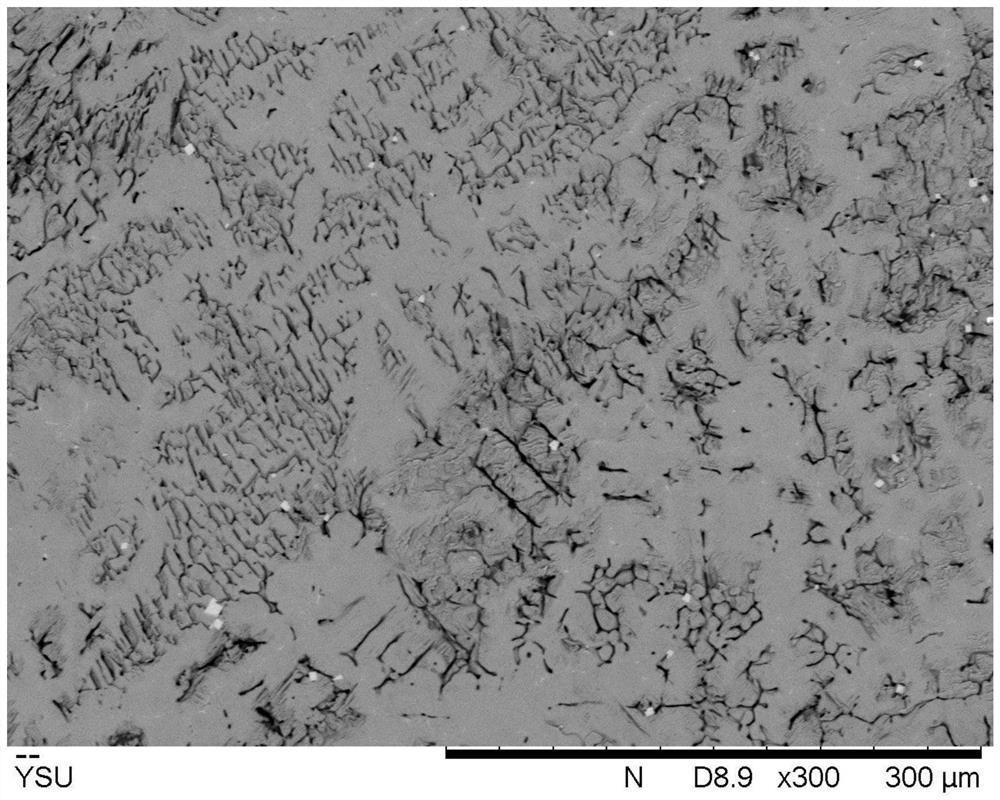

[0053] The high-strength corrosion-resistant zirconium-containing stainless steel provided in Example 1 includes the following components in mass percentage: 0.5% zirconium, 0.5% titanium, 0.01% hafnium, 0.3% carbon, 0.7% silicon, 1.8% manganese, 17% chromium, and 15% nickel %, molybdenum 2.3%, the balance iron. After the above mass percentages of zirconium, titanium, hafnium, carbon, silicon, manganese, chromium, nickel, molybdenum and iron are ultrasonically cleaned in acetone and alcohol, the raw materials are sequentially cleaned of Fe, Al , Mn, C, Ni, Si, Ti, Cr, Hf, Mo were placed in the water-cooled copper crucible of the non-consumable vacuum arc melting furnace that had been polished and scrubbed in advance, and the vacuum degree in the furnace cavity was set to 2×10 -2 Pa, filled with high-purity argon as a protective gas before smelting, and added magnetic suspension stirring to make it evenly mixed. Repeated smelting and flipping the ingot five times to obtain an ...

Embodiment 2

[0057] The high-strength corrosion-resistant zirconium-containing stainless steel provided in Example 2 includes the following components in mass percentage: 3% zirconium, 1.5% titanium, 0.1% hafnium, 0.3% carbon, 0.7% silicon, 1.8% manganese, 17% chromium, and 15% nickel %, molybdenum 2.3%, the balance iron. After the above mass percentages of zirconium, titanium, hafnium, carbon, silicon, manganese, chromium, nickel, molybdenum and iron are ultrasonically cleaned in acetone and alcohol, the raw materials are sequentially cleaned of Fe, Al , Mn, C, Ni, Si, Ti, Cr, Hf, Mo were placed in the water-cooled copper crucible of the non-consumable vacuum arc melting furnace that had been polished and scrubbed in advance, and the vacuum degree in the furnace cavity was set to 1.4×10 - 2 Pa, filled with high-purity argon as a protective gas before smelting, and added magnetic suspension stirring to make it evenly mixed. Alloy ingots were obtained by repeatedly smelting and turning th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com