A high-concentration full tailings cemented continuous filling device and filling method

A filling device and filling method technology, which is applied in safety devices, fillings, earthwork drilling and mining, etc., can solve the problems of insufficient running time, poor controllability of filling slurry concentration and flow rate, overflow water running and mixing, etc., so as to improve the concentration Controllability of flow rate, improvement of single-day filling capacity, and effect of ensuring filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

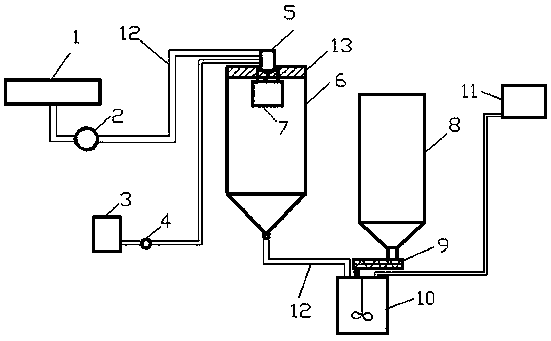

[0019] The present invention includes a concentration tank 1, a flocculation tank 3, a vertical sand bin 6, a cement bin 8, a mixing tank 10, and a high-level pool 11.

[0020] Shown in the figure, thickening pool 1 is connected with the upper end of vertical sand bin 6 by conveying pipeline 12, sand pump 2 is installed in the conveying pipeline 12 that thickening pool 1 is connected with vertical sand bin 6, to vertical sand bin 6 Conveying mortar. The concentration range of tailings in concentration tank 1 is 20%~40%, which can continuously provide 100~120t / h of dry sand.

[0021] As shown in the figure, the flocculation tank 3 is connected to the upper end of the vertical sand bin 6 through a delivery pipe 12, and a screw pump 4 is installed in the delivery pipe 12 connecting the flocculation tank 3 and the vertical sand bin 6. The flocculation tank 3 transports the chemical solution of the flocculation tank to the vertical sand bin 6 through the delivery pipeline 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com