Production method for kitasamycin solid micro-capsules for feed

A technology for the production of kitasamycin and its production method, which is applied in the field of production of kitasarmycin solid microcapsules for feed, can solve the problems of affecting the effect, difficulty in contact, complex components, etc., and achieves inhibition of dissolution, improvement of stability, and taste Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

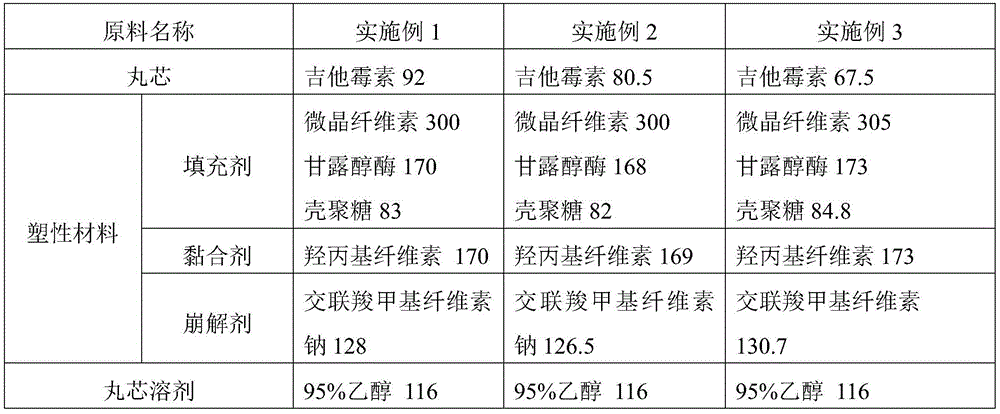

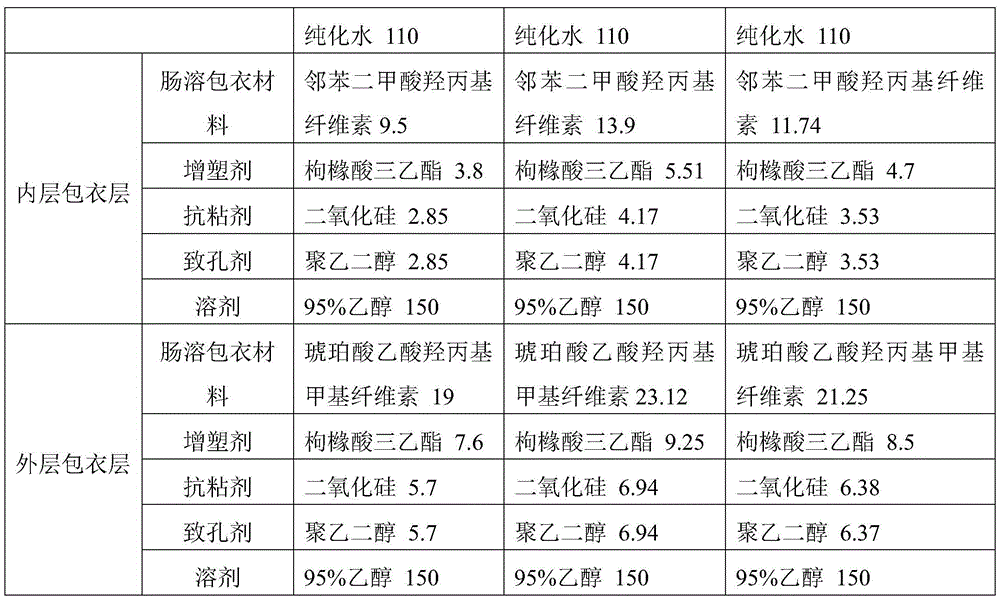

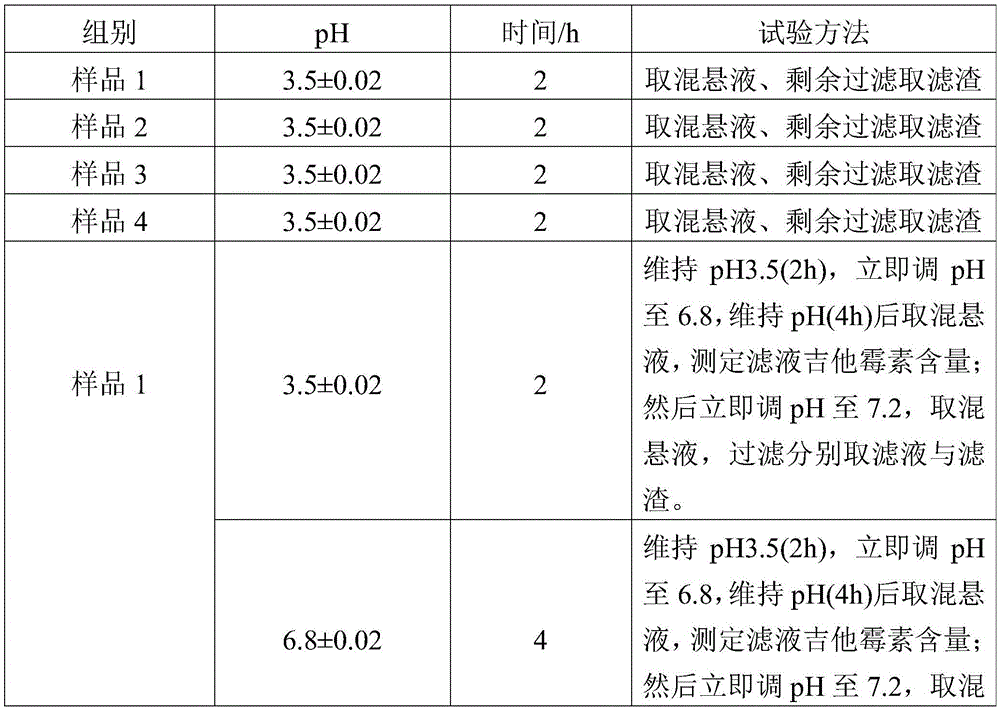

[0036] Each raw material consumption of embodiment 1~3 is as shown in table 1:

[0037] Table 1 (unit: kg)

[0038]

[0039]

[0040] The above-mentioned 95% ethanol is the weight fraction.

[0041] The preparation technology of embodiment 1~3 is:

[0042] (1) Accurately weigh kitasamycin, plastic material, 95% ethanol and purified water separately.

[0043] (2) Mix 95% ethanol and purified water evenly, set aside. Dissolve the plastic material in the above ethanol solution.

[0044] (3) Turn on the high-speed mixing granulator, add the raw materials of the ball core, mix well, slowly add the raw materials into the high-speed mixing granulator, and mix well to obtain a soft material.

[0045] (4) Put the soft material in the extruder, select a screen with an aperture of 1.0mm, and extrude strips with uniform thickness and length.

[0046] (5) Place the strips in a spheronizer, adjust the spheronization frequency to 20 Hz, and spheronize for 15 minutes. Under the joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com