Preparation method of molybdenum disulfide-silver sulfide composite nano-grade adsorption-photocatalyst

A molybdenum disulfide and nano-adsorption technology, applied in the field of nano-materials, can solve the problems of hindering development and low utilization rate of visible light, and achieve the effects of low cost, excellent photocatalytic performance, and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

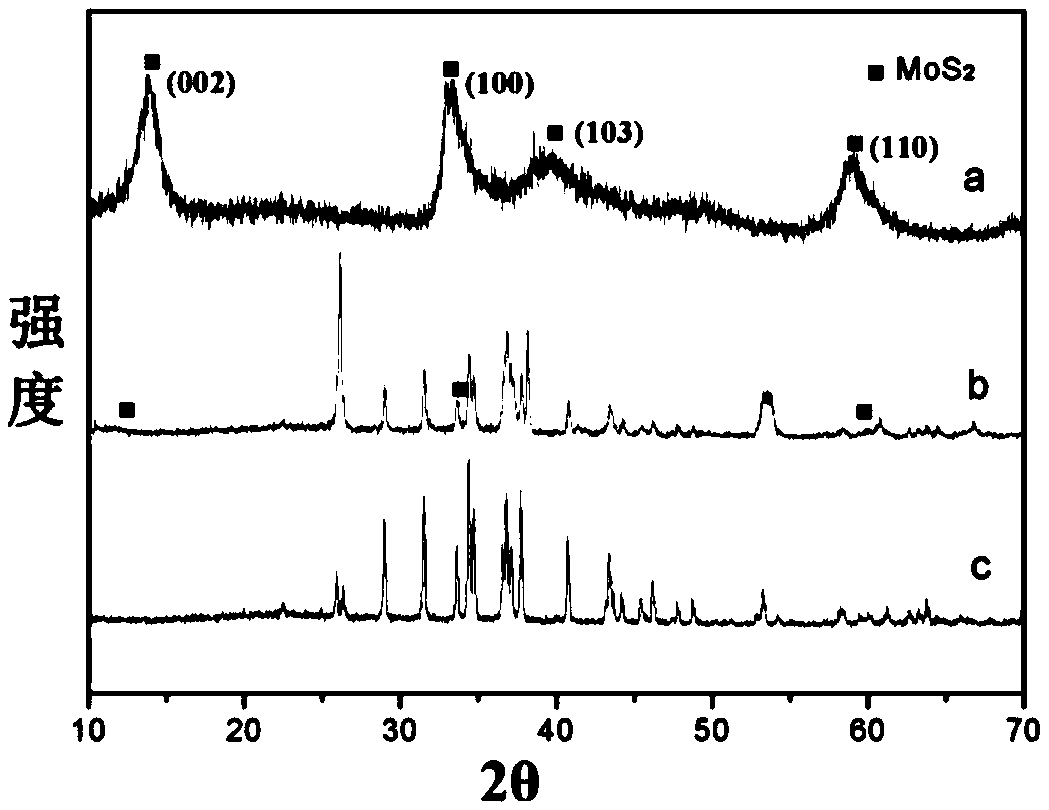

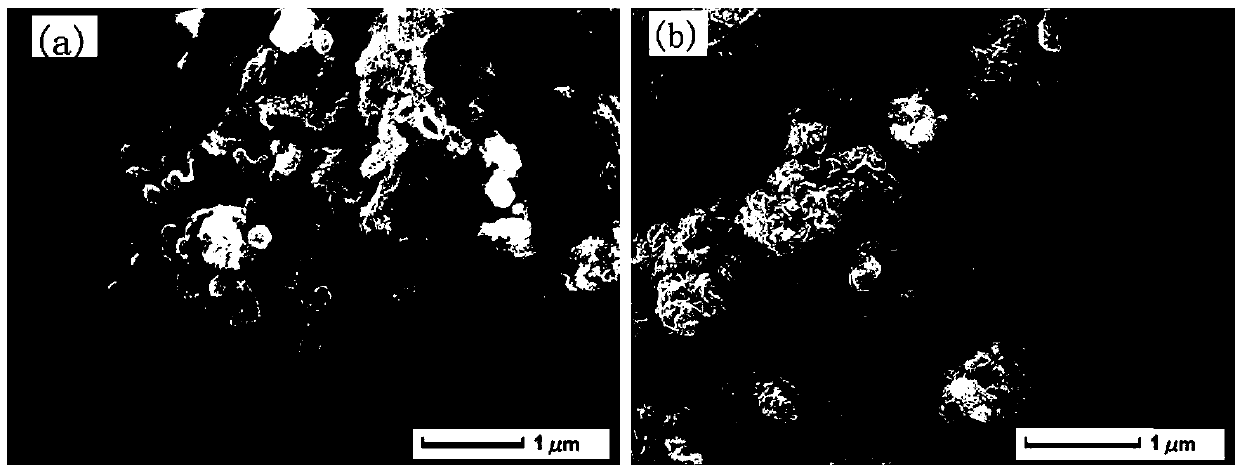

[0019] 0.24g (NH 4 ) 2 MoO 4 , 0.32gKSCN and 0.28gNH 2 OH·HCl was dissolved in 60 mL of deionized water. After completely dissolving, continue to stir for 30 min, then transfer the mixture to a 100 mL stainless steel reaction kettle, place it in a vacuum drying oven at 180°C for 24 h, and cool to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, that is, molybdenum disulfide nanoflowers.

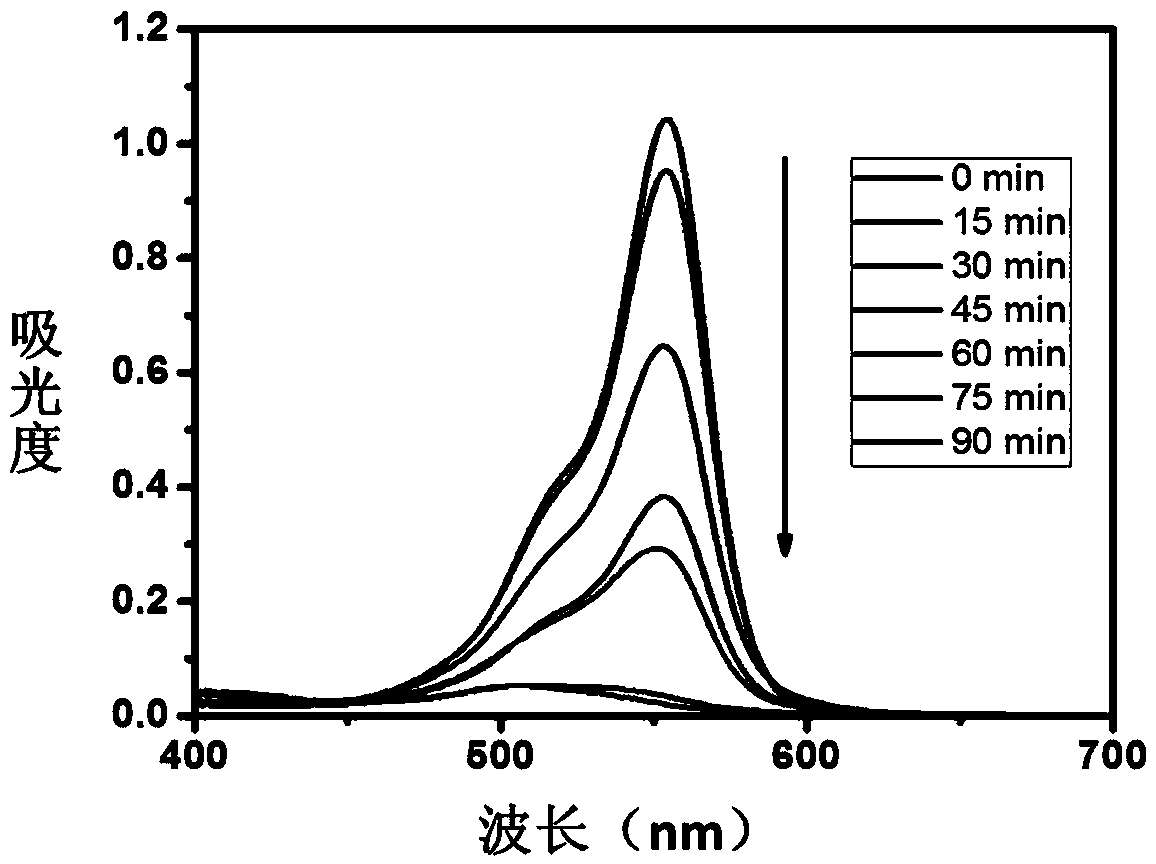

[0020] 0.85gAgNO 3 and 0.16g of molybdenum disulfide were dispersed in 60mL of deionized water, and after stirring for 30min, the mixture was transferred to a 100mL stainless steel reaction kettle, placed in a vacuum oven at 160°C for 24h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and final...

Embodiment 2

[0023] 0.24g (NH 4 ) 2 MoO 4 , 0.32gKSCN and 0.28gNH 2 OH·HCl was dissolved in 60 mL of deionized water. After completely dissolving, continue to stir for 30 min, then transfer the mixture to a 100 mL stainless steel reaction kettle, place it in a vacuum drying oven at 180°C for 24 h, and cool to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, that is, molybdenum disulfide nanoflowers.

[0024] 0.17gAgNO 3 and 0.16g of molybdenum disulfide were dispersed in 60mL of deionized water, and after stirring for 30min, the mixture was transferred to a 100mL stainless steel reaction kettle, placed in a vacuum oven at 160°C for 24h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and final...

Embodiment 3

[0027] 0.24g (NH 4 ) 2 MoO 4 , 0.32gKSCN and 0.28gNH 2 Dissolve OH·HCl in 60 mL of deionized water. After completely dissolving, continue to stir for 30 min, then transfer the mixture to a 100 mL stainless steel reaction kettle, place it in a vacuum oven at 320°C for 18 h, and cool to room temperature. After the reaction product was separated by centrifugation, it was repeatedly washed with deionized water and absolute ethanol, and finally dried at 80° C. for 10 h under vacuum to obtain a gray-black product powder, that is, molybdenum disulfide nanoflowers.

[0028] 0.54gAgNO 3 and 0.16g of molybdenum disulfide were dispersed in 60mL of deionized water, and after stirring for 30min, the mixture was transferred to a 100mL stainless steel reaction kettle, placed in a vacuum oven at 120°C for 24h, and cooled to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com