Composite adsorption material with MAR and MIL-53 (Al) combined and preparation method thereof

A technology of composite adsorption materials and composite materials, which is applied in the field of air pollutant purification materials, can solve the problems that MOFs cannot be assembled into air filters, molecules are easy to pass through pores, and filtration applications are not good, so as to achieve strong adsorption application potential, The effect of good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

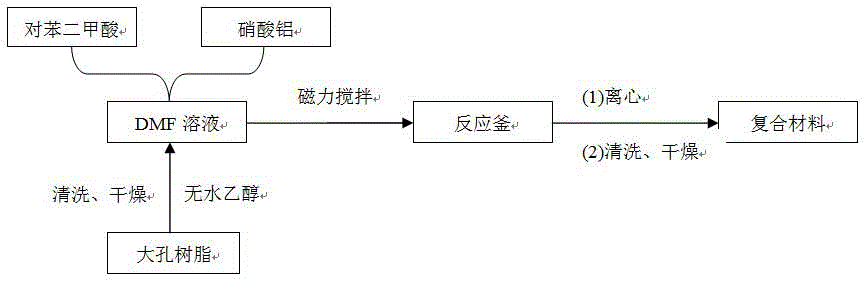

Method used

Image

Examples

Embodiment 1

[0022] Add 1.245g of terephthalic acid and 4.220g of aluminum nitrate into the DMF solution with a volume fraction of 60%, and stir at 80°C until the terephthalic acid and aluminum nitrate are completely dissolved. Then, select the pore diameter of the porous resin to be 120nm, wash with absolute ethanol and a large amount of water, and vacuum-dry, add the dried macroporous adsorption resin to the above solution, and magnetically stir at 65°C for 25h. The mixed solution was transferred to a Teflon-lined reactor and heated at 130° C. for 48 h. After the reaction, the obtained milky precipitate was centrifuged and washed with methanol and dichloromethane to remove unreacted organic ligands. Finally, the obtained sample was vacuum-dried in a vacuum oven at 80°C for 24 hours to obtain a composite adsorbent material combining MAR and MIL-53 (Al).

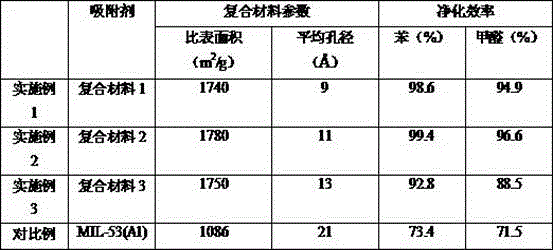

[0023] The prepared composite material 1 was passed through a mixed gas composed of benzene, formaldehyde and nitrogen, and a static a...

Embodiment 2

[0025] Add 1.245g of terephthalic acid and 4.220g of aluminum nitrate into the DMF solution with a volume fraction of 60%, and stir at 80°C until the terephthalic acid and aluminum nitrate are completely dissolved. Then, select the pore diameter of the porous resin to be 200nm, wash with absolute ethanol and a large amount of water, and vacuum-dry, add the dried macroporous adsorption resin to the above solution, and magnetically stir at 65°C for 25h. The mixed solution was transferred to a Teflon-lined reactor and heated at 130° C. for 48 h. After the reaction, the obtained milky precipitate was centrifuged and washed with methanol and dichloromethane to remove unreacted organic ligands. Finally, the obtained sample was vacuum-dried in a vacuum oven at 80°C for 24 hours to obtain a composite adsorbent material combining MAR and MIL-53 (Al).

[0026] The prepared composite material 2 was passed through a mixed gas composed of benzene, formaldehyde and nitrogen, and a static a...

Embodiment 3

[0028] Add 1.245g of terephthalic acid and 4.220g of aluminum nitrate into the DMF solution with a volume fraction of 60%, and stir at 80°C until the terephthalic acid and aluminum nitrate are completely dissolved. Then, select the pore diameter of the porous resin to be 300nm, wash with absolute ethanol and a large amount of water, and vacuum-dry, add the dried macroporous adsorption resin to the above solution, and magnetically stir at 65°C for 25h. The mixed solution was transferred to a Teflon-lined reactor and heated at 130° C. for 48 h. After the reaction, the obtained milky precipitate was centrifuged and washed with methanol and dichloromethane to remove unreacted organic ligands. Finally, the obtained sample was vacuum-dried in a vacuum oven at 80°C for 24 hours to obtain a composite adsorbent material combining MAR and MIL-53 (Al).

[0029] The obtained composite material 3 was passed through a mixed gas composed of benzene, formaldehyde and nitrogen, and a static a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com