Iron-aluminum composite metal oxide micro-nano material and preparation method thereof, and degradation method for polybrominated diphenyl ethers

A polybrominated diphenyl ether and composite metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve a simple and easy preparation method, low cost and low reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides an iron-aluminum composite metal oxide micro-nano material, a preparation method and a polybrominated diphenyl ether degradation method. The iron-aluminum composite metal oxide micro-nano material is a micron particle composed of nanoparticles, and its phase is composed of iron and aluminum A composite metal oxide, wherein the atomic ratio of iron and aluminum is 1-10:1-10. The iron-aluminum composite metal oxide micro-nano material of the invention can degrade polybrominated diphenyl ethers stably, efficiently, quickly and at low temperature, the material is beneficial to recovery, and the preparation method is simple and easy, and the cost is low.

[0024] According to one embodiment of the present invention, the iron-aluminum composite metal oxide micro-nano material is a micron particle composed of nanoparticles, and its phase is a composite metal oxide composed of iron and aluminum, wherein the atomic ratio of iron and aluminum The particle s...

Embodiment approach

[0025] According to one embodiment of the present invention, the preparation method of iron-aluminum composite metal oxide micro-nano material comprises:

[0026] S1, dissolve iron salt and aluminum salt in water, add urea to the solution, mix and stir, transfer the solution to a stainless steel reactor for hydrothermal reaction, wherein the atomic ratio of iron and aluminum is 0.1~ 10;

[0027] S2, cool the solution to room temperature, collect the precipitate, wash the precipitate with distilled water and absolute ethanol and centrifuge, and dry in an oven to obtain the iron-aluminum composite metal oxide micro / nano material, wherein the drying temperature is 60°C, and the drying time is For 6 ~ 8h.

[0028] According to one embodiment of the present invention, iron salt and aluminum salt are nitrate or oxalate, can be Al(NO 3 ) 3 ·6H 2 O, the iron salt can be ferric ammonium oxalate.

[0029] According to one embodiment of the present invention, the concentration of ir...

Embodiment 1

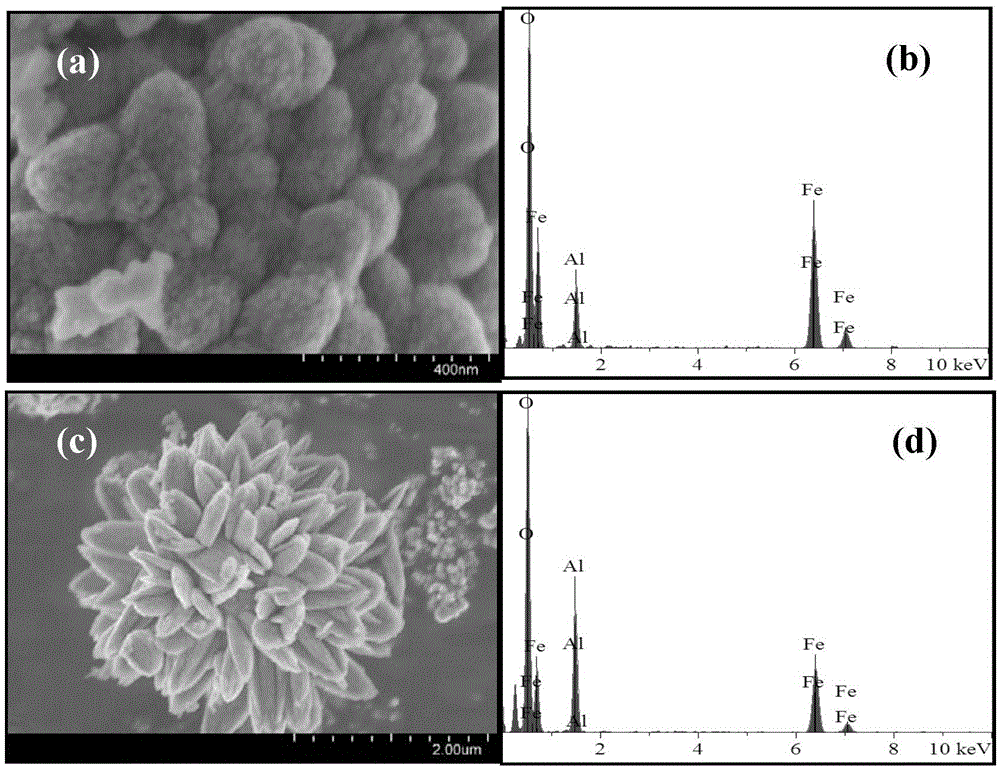

[0034] Take Al(NO 3 ) 3 ·6H 2 O0.9634g, ferric ammonium oxalate 0.7467g, urea 9mmol and distilled water 40mL were placed in a 100mL beaker, electromagnetically stirred at room temperature for 30min, and then transferred to a 50mL stainless steel reaction kettle. Put the reactor into an oven at 180°C for 12 hours. After the reaction was completed, it was cooled to room temperature, and the precipitate was collected. The precipitate was washed with distilled water and absolute ethanol, and dried at 60°C for several hours. The iron-aluminum composite micro / nano metal oxide can be obtained. Its SEM and EDX characterization results are as follows figure 1 As shown, the SEM images of (a) and (c) show that the prepared material is a spherical and flower-like micro-nano structure material, and the EDX characterization results of (b) and (d) show that it contains two metal elements, iron and aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com