Soldering lug for welding power module

A technology for power modules and solder tabs, which is used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as excessive temperature, and achieve the effects of good heat conduction, enhanced heat dissipation, and high heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

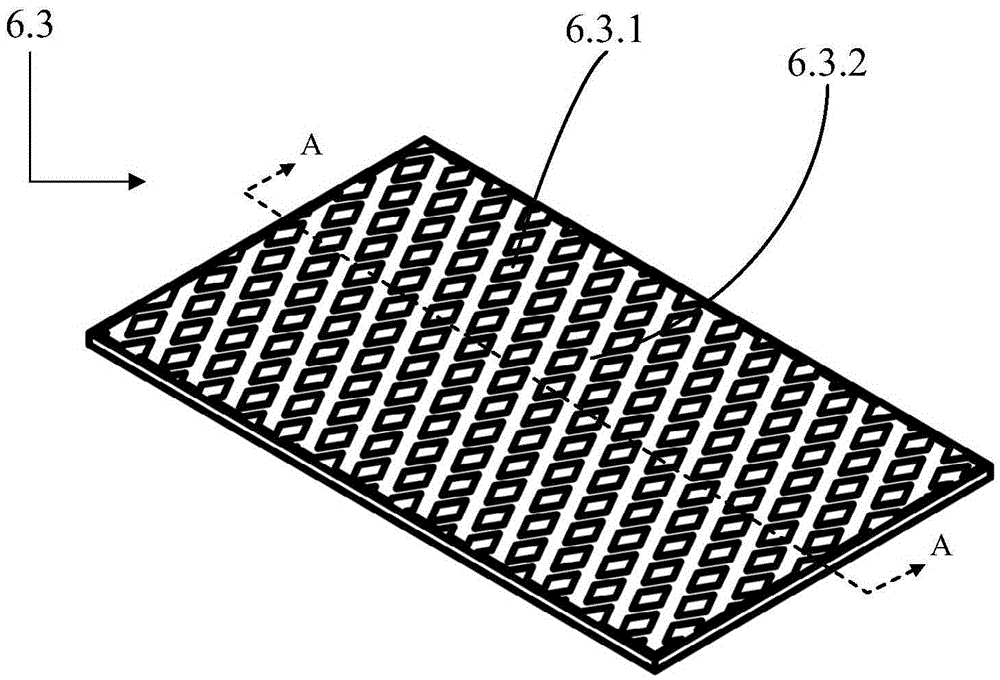

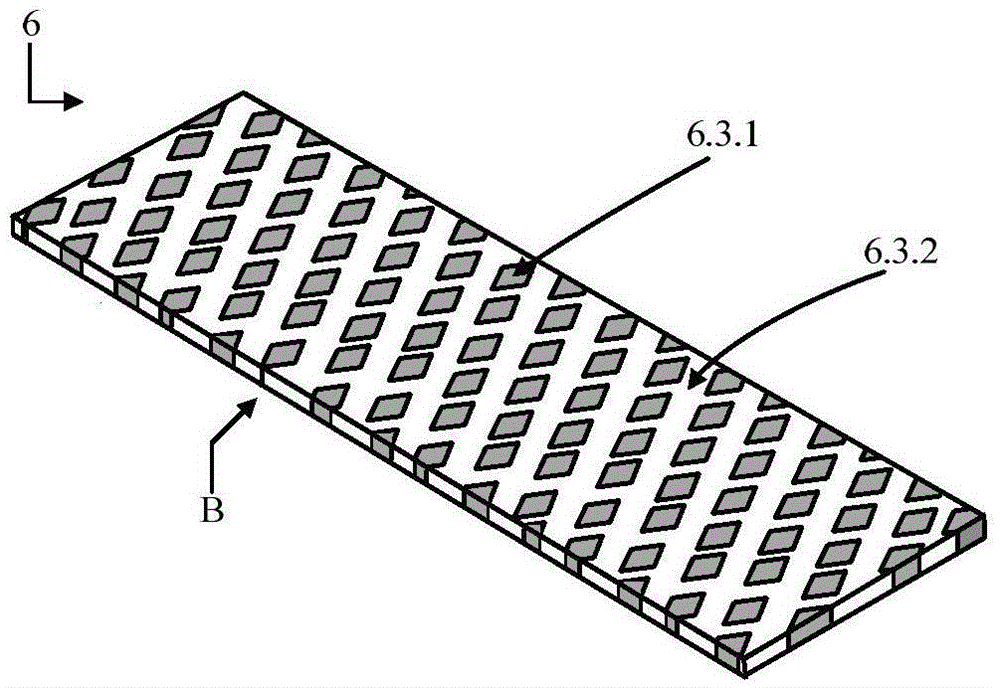

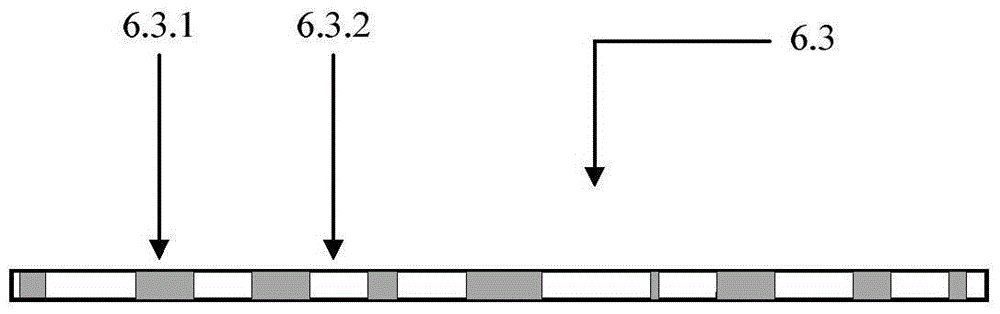

[0022] A solder sheet for power module welding, comprising a metal mesh skeleton 6.3.2, and brazing materials are filled in the meshes of the metal mesh skeleton 6.3.2. In this embodiment, the metal mesh skeleton is a metal material including copper Cu, silver Ag, gold Au or alloys with a liquidus temperature greater than 450°C, and the thermal conductivity of the metal material is better than that of ordinary solder The thermal conductivity of the solder sheet; the brazing material is a brazing material with a liquidus temperature between 150°C and 450°C, including tin Sn, tin-lead alloy, and tin-lead-silver alloy; the thickness of the solder sheet is 80 μm to 110 μm , wherein, the mesh skeleton metal material (6.3.2) is consistent with the thickness of the solder sheet, and the brazing material is filled to 98% to 99% of the mesh inner space.

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific implementation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com