A kind of preparation method of high-strength, low-density lightweight bicycle frame

A low-density, bicycle technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of tearing, easy peeling of products, poor plastic deformation ability of magnesium alloys, etc., to ensure the strength and avoid peeling. and tearing, the effect of good hysteresis shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

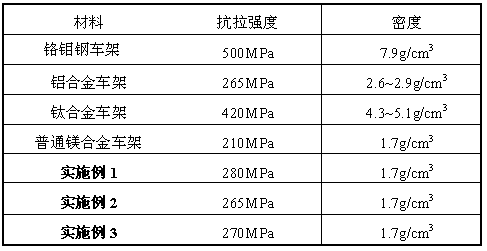

Examples

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of high-strength, low-density lightweight bicycle frame, comprises the following steps:

[0044] ⑴ Preparation of magnesium alloy ingot:

[0045] Preheat magnesium ingot 940kg, aluminum ingot 7kg, zinc ingot 21kg, Al-20Ti master alloy 12kg, Mg-50Nd master alloy 4.2kg, Mg-50Y master alloy 7.5kg, Mg-50Ce master alloy 1.4kg to 100~130 ℃, then put the magnesium ingot, aluminum ingot and zinc ingot in CO 2 Melted in a furnace protected by mixed gas with Ar; after melting, keep it at 650~690°C for 45 minutes, then raise the temperature to 760~790°C, at this time, add Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy, Mg-50Ce master alloy, after the Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy and Mg-50Ce master alloy are melted, the magnesium liquid is heated to 770~800°C and kept for 50 minutes; then cooled to 650~ 700°C, after standing for 20 minutes, cast with a steel mold pre-heated to 150-200°C ...

Embodiment 2

[0064] Embodiment 2 A preparation method of a high-strength, low-density lightweight bicycle frame, comprising the following steps:

[0065] ⑴ Preparation of magnesium alloy ingot:

[0066] Preheat magnesium ingot 960kg, aluminum ingot 57kg, zinc ingot 18kg, Al-20Ti master alloy 10kg, Mg-50Nd master alloy 3.6kg, Mg-50Y master alloy 7.0kg, Mg-50Ce master alloy 1.2kg to 130~160 ℃, then put the magnesium ingot, aluminum ingot and zinc ingot in CO 2 Melted in a furnace protected by mixed gas with Ar; after melting, keep it at 690~730°C for 35 minutes, then raise the temperature to 790~820°C, at this time, add Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy, Mg-50Ce master alloy, after the Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy and Mg-50Ce master alloy are melted, the magnesium liquid is heated to 800~830℃ and kept for 40 minutes; then cooled to 700~ 750°C, after standing for 15 minutes, cast with a steel mold preheated to 200~250°C to obt...

Embodiment 3

[0085] Embodiment 3 A preparation method of a high-strength, low-density lightweight bicycle frame, comprising the following steps:

[0086] ⑴ Preparation of magnesium alloy ingot:

[0087] Preheat 980kg of magnesium ingot, 3kg of aluminum ingot, 15kg of zinc ingot, 8kg of Al-20Ti master alloy, 3.0kg of Mg-50Nd master alloy, 6.5kg of Mg-50Y master alloy, and 1.0kg of Mg-50Ce master alloy to 160~180 ℃, then put the magnesium ingot, aluminum ingot and zinc ingot in CO 2 Melted in a furnace protected by mixed gas with Ar; after melting, keep it at 730~760°C for 25 minutes, then raise the temperature to 820~840°C, at this time, add Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy, Mg-50Ce master alloy, after the Al-20Ti master alloy, Mg-50Nd master alloy, Mg-50Y master alloy and Mg-50Ce master alloy are melted, the magnesium liquid is heated to 830~860°C and kept for 30 minutes; then cooled to 750~ 800°C, after standing for 10 minutes, cast with a steel mold pre-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| traction force | aaaaa | aaaaa |

| traction force | aaaaa | aaaaa |

| traction force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com